Zvedací řetěz ze slitiny třídy 80 Chian

1. Krátkočlánkový zvedací řetěz DIN En818-2 G80 je vyroben z legované oceli a je to všeobecně použitelný řetěz pro zvedání nad hlavou nebo tažení.

2. Řetěz G80 má dlouhý a krátký článek. Řetěz s dlouhým článkem má větší vnitřní délku, aby se snížila hmotnost a náklady. Obecně jsou řetězy s krátkými články pružnější než řetězy s dlouhými články.

| Chain Size (in) | Spec. 8 Drum Stock No. | Feet Per Drum | Material Size (in) | Working Load Limit (lb)* | Maximum Inside Length (in) | Maximum Inside Width (in) | Maximum Length 100 Links (in) | Weight Per 100 Feet (lb) |

|---|---|---|---|---|---|---|---|---|

| 9/32 (1/4) | 273527 | 500 | 0.276 | 3500 | 0.87 | 0.42 | 90 | 72 |

| 5/16 | 273536 | 500 | 0.343 | 4500 | 1.01 | 0.49 | 100 | 114 |

| 3/8 | 273545 | 500 | 0.394 | 7100 | 1.23 | 0.58 | 125 | 148 |

| 1/2 | 273554 | 300 | 0.512 | 12000 | 1.57 | 0.77 | 164 | 243 |

| 5/8 | 273563 | 200 | 0.63 | 18100 | 1.93 | 0.9 | 202 | 351 |

| 3/4 | 273572 | 100 | 0.787 | 28300 | 2.42 | 1.14 | 252 | 584 |

| 7/8 | 273581 | 100 | 0.866 | 34200 | 2.66 | 1.26 | 277 | 705 |

| 1 | 273590 | 75 | 1.024 | 47700 | 3.28 | 1.54 | 328 | 1041 |

| 1-1/4 | 273599 | 66 | 1.26 | 72300 | 4.03 | 1.89 | 403 | 1478 |

Grade 80 alloy chains are a staple in lifting and rigging operations that demand high strength, safety, and resilience. Known for their exceptional load-bearing capacity and durability, Grade 80 chains are engineered from a special alloy steel, ensuring high tensile strength and flexibility, even in challenging environments. These chains are designed to perform consistently under demanding conditions, making them an invaluable asset in heavy-duty lifting, material handling, and transport sectors.

The meticulous manufacturing of Grade 80 chains begins with alloy steel, which is heat-treated to provide an optimal balance of hardness and ductility. The material composition allows the chain to withstand the impact, bending, and stress associated with high-weight applications without compromising its structural integrity. This durability ensures a longer lifespan, which can reduce replacement frequency and maintenance costs, making these chains a practical and cost-effective choice. For buyers, this balance between strength and longevity is essential, particularly in environments where reliability can directly impact productivity and safety.

Short link chain

| Model | Stock No. | Chain Dia. (mm) | Link Dimensions (mm) | Breaking Load (t) | Hmotnost (kg) | Standard Length (m) | ||

|---|---|---|---|---|---|---|---|---|

| Pitch | Width | Trawlex® | Grade 80 | |||||

| TRAW-SL | 2781650 | 10 | 30 | 14 | 15.5 | 12 | 2.2 | 200 |

| TRAW-SL | 2781652 | 13 | 39 | 18.1 | 26.5 | 20 | 3.61 | 150 |

| TRAW-SL | 2781635 | 16 | 48 | 22.4 | 41 | 30 | 5.41 | 110 |

| TRAW-SL | 2781644 | 19 | 57 | 26.6 | 57 | 45 | 7.81 | 75 |

Mid link chain

| Model | Stock No. | Chain Dia. (mm) | Link Dimensions (mm) | Breaking Load (t) | Hmotnost (kg) | Standard Length (m) | ||

|---|---|---|---|---|---|---|---|---|

| Pitch | Width | Trawlex® | Grade 80 | |||||

| TRAW-SL | 2781650 | 10 | 30 | 14 | 15.5 | 12 | 2.2 | 200 |

| TRAW-SL | 2781652 | 13 | 39 | 18.1 | 26.5 | 20 | 3.61 | 150 |

| TRAW-SL | 2781635 | 16 | 48 | 22.4 | 41 | 30 | 5.41 | 110 |

| TRAW-SL | 2781644 | 19 | 57 | 26.6 | 57 | 45 | 7.81 | 75 |

Long link chain

| Model | Stock No. | Chain Dia. (mm) | Link Dimensions (mm) | Breaking Load (t) | Hmotnost (kg) | Standard Length (m) | ||

|---|---|---|---|---|---|---|---|---|

| Pitch | Width | Trawlex® | Grade 80 | |||||

| TRAW-LL | 2781699 | 9 | 53 | 15 | 12.5 | 10 | 1.36 | 200 |

| TRAW-LL | 2781706 | 11 | 63 | 18 | 18.5 | 15 | 2.03 | 150 |

| TRAW-LL | 2781715 | 13 | 80 | 22 | 26.5 | 20 | 2.83 | 150 |

| TRAW-LL | 2781720 | 13 | 80 | 22 | 26.5 | 20 | 2.83 | 600 |

| TRAW-LL | 2784339 | 16 | 100 | 24.5 | 40 | 30 | 4.34 | 100 |

| TRAW-LL | 2784348 | 16 | 100 | 24.5 | 40 | 30 | 4.34 | 600 |

| TRAW-LL | 2781724 | 16 | 100 | 24.5 | 40 | 30 | 4.34 | 100 |

| TRAW-LL | 2784320 | 16 | 100 | 24.5 | 40 | 30 | 4.34 | 600 |

| TRAW-LL | 2784357 | 19 | 100 | 25 | 57 | 45 | 6.31 | 108 |

| TRAW-LL | 2781733 | 19 | 100 | 25 | 57 | 45 | 6.31 | 108 |

| TRAW-LL | 2781742 | 22 | 120 | 35.5 | 70 | 60 | 8.74 | 70 |

| TRAW-LL | 2781751 | 28 | 150 | 46 | 105 | 95 | 14.41 | 50 |

Applications and Performance Characteristics

The versatility of Grade 80 alloy chains makes them ideal for a variety of industrial settings. These chains are especially popular in construction, mining, and maritime operations, where they encounter challenging conditions such as abrasion, extreme loads, and varying weather. Because these applications require equipment that can withstand intense wear and harsh environments, Grade 80 chains are engineered to meet these specific challenges with minimal degradation over time.

Each Grade 80 chain is typically rated for specific working load limits (WLL), a parameter that determines how much weight the chain can safely bear without risk of failure. The high WLL of these chains provides operational flexibility, allowing them to be used in dynamic environments with changing load demands. Understanding the importance of precise load ratings, our team at Qingdao H&F provides detailed product information and test reports to assure buyers that each chain meets their required standards. Additionally, we ensure rapid delivery to keep supply lines moving, a crucial advantage for clients operating under tight project deadlines.

To ensure compatibility and longevity, Grade 80 alloy chains undergo rigorous testing, with each chain meticulously examined to detect imperfections. By offering various inspection reports, Qingdao H&F helps clients maintain a high level of safety in their operations. Each inspection includes proof testing to verify the chain’s strength under typical and peak load conditions, ensuring a product that lives up to its reputation for reliability. This level of testing not only confirms the chain’s performance but also helps buyers manage long-term costs, as dependable chains reduce the need for frequent replacements.

Why Choose Qingdao H&F for Grade 80 Alloy Chains?

Qingdao H&F stands out as a trusted supplier of Grade 80 alloy chains for our commitment to quality, transparency, and service. Our company focuses on building lasting relationships with our buyers, prioritizing their operational needs and offering tailored solutions to meet even the most complex project requirements. With our one-on-one customer service, each client benefits from personalized guidance throughout the buying process, from initial inquiry to post-purchase support.

In addition to providing top-tier products, our quick delivery cycle enables clients to keep their schedules on track without waiting for long lead times. This rapid turnaround time is especially important in industries where downtime can significantly impact productivity and profitability. Furthermore, by providing a comprehensive set of quality inspection reports, we allow buyers to verify product integrity and performance before deployment. This focus on quality and transparency ensures our clients can have complete confidence in the chains they purchase.

In every aspect of our business, from product development to customer relations, Qingdao H&F aims to exceed industry standards. We invest in quality assurance at every stage to ensure that our Grade 80 alloy chains offer a long service life and robust performance. As your partner, we take pride in delivering not just products, but a premium purchasing experience that brings peace of mind and confidence, so you can focus on your core operations.

Co nás odlišuje

1. Specializovaný individuální zákaznický servis 24/7

Náš tým je nepřetržitě k dispozici, aby vám poskytl individuální podporu a okamžitě řešil jakékoli dotazy nebo problémy, a zajistil tak bezproblémové a spolehlivé služby.

2. Rozsáhlé skladové zásoby, konkurenceschopné ceny a vzorky zdarma

Udržujeme rozsáhlé skladové zásoby, které umožňují rychlé a spolehlivé plnění. Naše konkurenceschopné ceny a bezplatné vzorky vám umožní posoudit kvalitu z první ruky a zajistí včasné a spolehlivé dodání v rámci každého projektového cyklu.

3. Důsledná kontrola kvality a komplexní inspekční zprávy

Náš přísný proces kontroly kvality zajišťuje, že všechny výrobky splňují nejvyšší standardy. Každá objednávka je podložena podrobnými zkušebními protokoly, které zajišťují klid a trvalou záruku kvality.

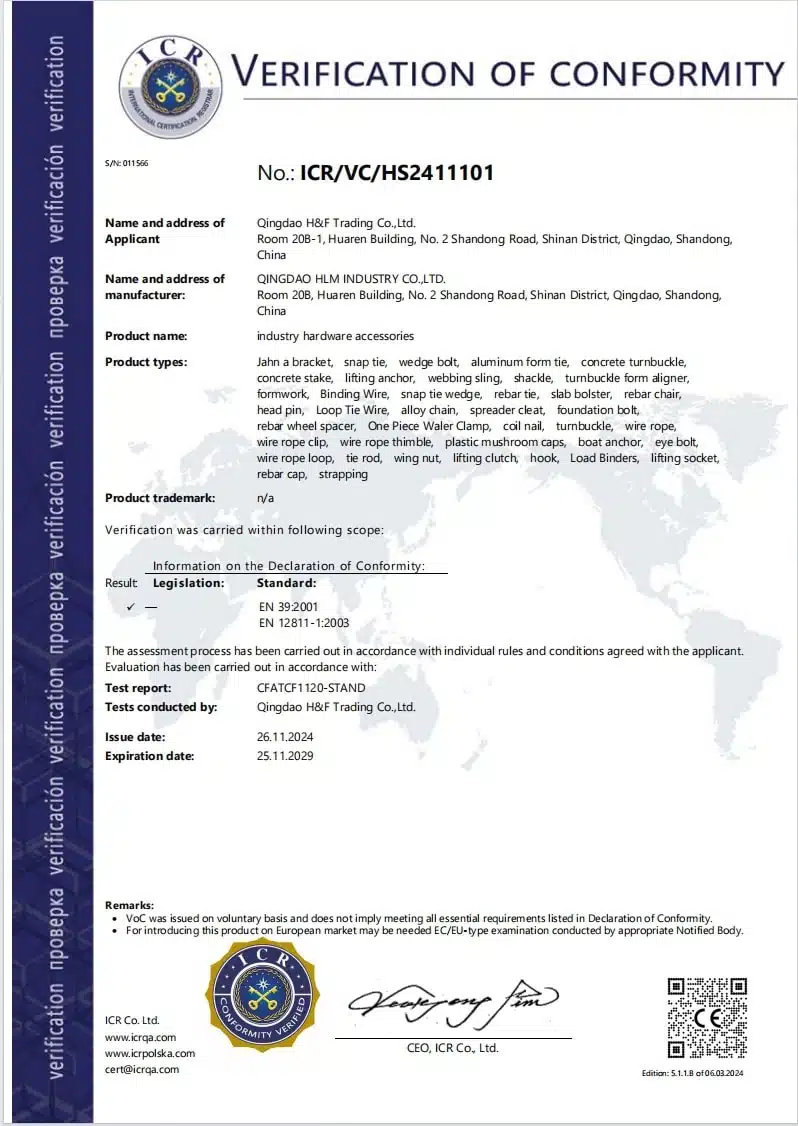

4. Certifikovaná excelence: Pro spolehlivé partnerství: CE a více

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Související produkty

-

Kotevní řetěz bez závitů

$0.01 -

Tažný řetěz s hákem J

$0.01