Veepeatus šabloonis

Formwork water stop products are essential for creating waterproof barriers in concrete construction, preventing water leakage through joints in concrete structures. These products are designed to be used in conjunction with other formwork accessories like tie rods and wing nuts to ensure a seamless and durable construction process. As a trading company, we offer one-to-one customer service, fast delivery cycles, and provide various quality inspection reports to ensure the highest standard for our customers. Whether you need advice on product specifications or timely delivery, we are committed to meeting your needs with efficiency and reliability.

Formwork water stop products are vital for waterproofing and maintaining structural integrity in concrete construction. These components work alongside formwork accessories like tie rods and wing nuts to prevent water seepage and protect concrete structures. Let’s explore how these elements work together and why they matter for your construction projects.

Understanding Formwork Water Stops

When building with concrete, you’ll inevitably deal with joints between different sections – these appear due to practical necessities like construction breaks or using separate mold sections. Since concrete is naturally porous, these joints can become weak points where water might penetrate. That’s where water stops come in.

Water stops are made from materials that can flex and move with the concrete – typically PVC, rubber, or special hydrophilic compounds. The key is choosing something that will maintain its effectiveness as the concrete settles and responds to environmental changes. You’ll need to install these before pouring concrete, creating a physical barrier against water infiltration. This is especially crucial for structures like basements, tunnels, and dams where water pressure is a constant concern.

The Role of Tie Rods in Formwork Applications

Tie rods (or formwork ties) are the unsung heroes of concrete construction. These steel components hold formwork panels steady while concrete is being poured and cured. By threading through the panels and securing with wing nuts at each end, they provide the tension needed to keep everything stable under the immense pressure of wet concrete.

The relationship between water stops and tie rods is crucial – they need to work together seamlessly. While tie rods maintain the formwork’s position, water stops ensure joint impermeability. Getting this combination right prevents water infiltration and costly future repairs. After the concrete sets, workers remove the tie rods and wing nuts, leaving behind properly waterproofed joints.

The Importance of Wing Nuts in Formwork Construction

Wing nuts might seem simple, but they’re essential for fine-tuning formwork installation. Their design allows workers to adjust tie rod tension by hand, making it easy to maintain proper panel alignment during concrete pours. This precise control helps prevent panel movement that could compromise the final structure.

These components also play a key role in water stop effectiveness. When tie rods are properly tensioned with wing nuts, they keep formwork panels and water stops exactly where they need to be. Without proper wing nut adjustment, movement during pouring could create gaps that allow water penetration.

Benefits of Formwork Water Stops in Waterproofing Concrete

For structures that face constant moisture exposure – like foundations and underground tunnels – proper waterproofing is non-negotiable. Water stops offer several key advantages:

Structural Protection: By preventing water infiltration at joints, water stops help avoid common problems like reinforcement corrosion and concrete degradation that can threaten structural integrity.

Cost Benefits: While the initial investment in quality water stops might seem significant, it’s far less expensive than dealing with water damage repairs later. Getting waterproofing right during construction eliminates the need for costly fixes down the line.

Enhanced Longevity: Structures with proper water stop installation typically last longer, especially in challenging environments with high water pressure or corrosive conditions.

Regulatory Compliance: Many construction codes mandate water stop use, particularly for critical infrastructure. Using them helps ensure your project meets all necessary safety and reliability standards.

Environmental Responsibility: Effective waterproofing protects not just the structure but also the surrounding environment from potential contamination through leaks.

Why Choose Us for Your Formwork Water Stop Needs?

Our company specializes in providing construction professionals with high-quality formwork solutions. We understand that every project has unique challenges, which is why we offer personalized support to help you select the right products.

We pride ourselves on quick delivery times and comprehensive quality inspection documentation. Whether you’re managing a major infrastructure project or a smaller development, our team provides the expertise and support you need throughout your project.

Kokkuvõte

The success of concrete construction often hinges on getting the details right – especially when it comes to waterproofing. Using water stops effectively, along with properly installed tie rods and wing nuts, helps ensure your structures remain watertight and durable. By partnering with a reliable supplier like us, you’ll get the quality products and support needed to complete your projects successfully.

Mis meid eristab

1. Pühendunud, 24/7 üks-ühele klienditeenindus

Meie meeskond on ööpäevaringselt kättesaadav, et pakkuda personaalset tuge ja lahendada kiiresti kõik küsimused või mured, tagades sujuva ja usaldusväärse kogemuse.

2. Ulatuslik varu, konkurentsivõimeline hinnakujundus ja tasuta näidised

Me säilitame tugeva varu, et toetada kiiret ja usaldusväärset täitmist. Meie konkurentsivõimelised hinnad ja tasuta näidised võimaldavad teil hinnata kvaliteeti vahetult, tagades õigeaegse ja usaldusväärse tarnimise iga projektitsükli jooksul.

3. Range kvaliteedikontroll ja põhjalikud inspekteerimisaruanded

Meie range kvaliteedikontrolliprotsess tagab, et kõik tooted vastavad kõrgeimatele standarditele. Iga tellimus on varustatud üksikasjalike katsearuannetega, mis tagavad meelerahu ja järjepideva kvaliteedi tagamise.

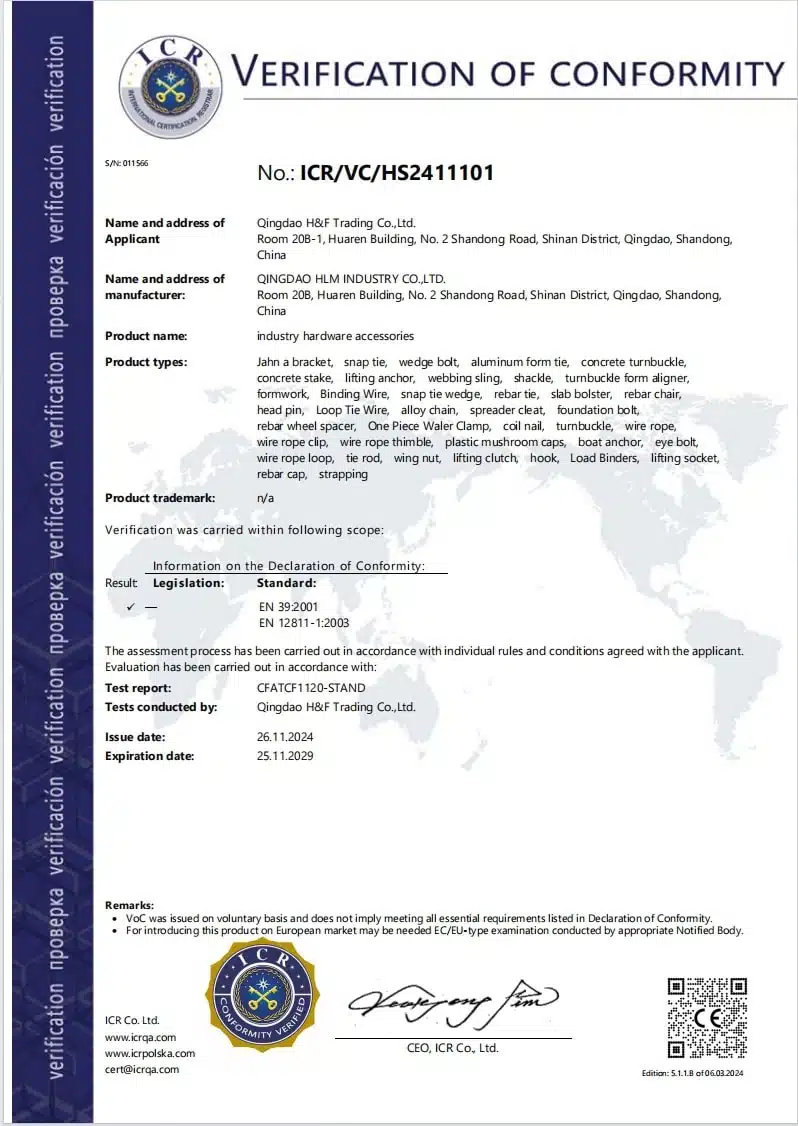

4. Sertifitseeritud tipptase: CE ja rohkem usaldusväärsetele partnerlustele

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Seotud tooted

-

Tie Rod PVC toru

$0.01 -

Steel Tie Rod koonus

$0.01 -

Betoonvalu Tie Rod

$0.01