كيفية استخدام نماذج الربط المفاجئ

Snap tie forms are a game-changer for anyone working with concrete, especially when building walls and other vertical structures. This article will break down the essential products in a snap tie system, show you how to use them effectively, and answer some common questions about snap tie forms.

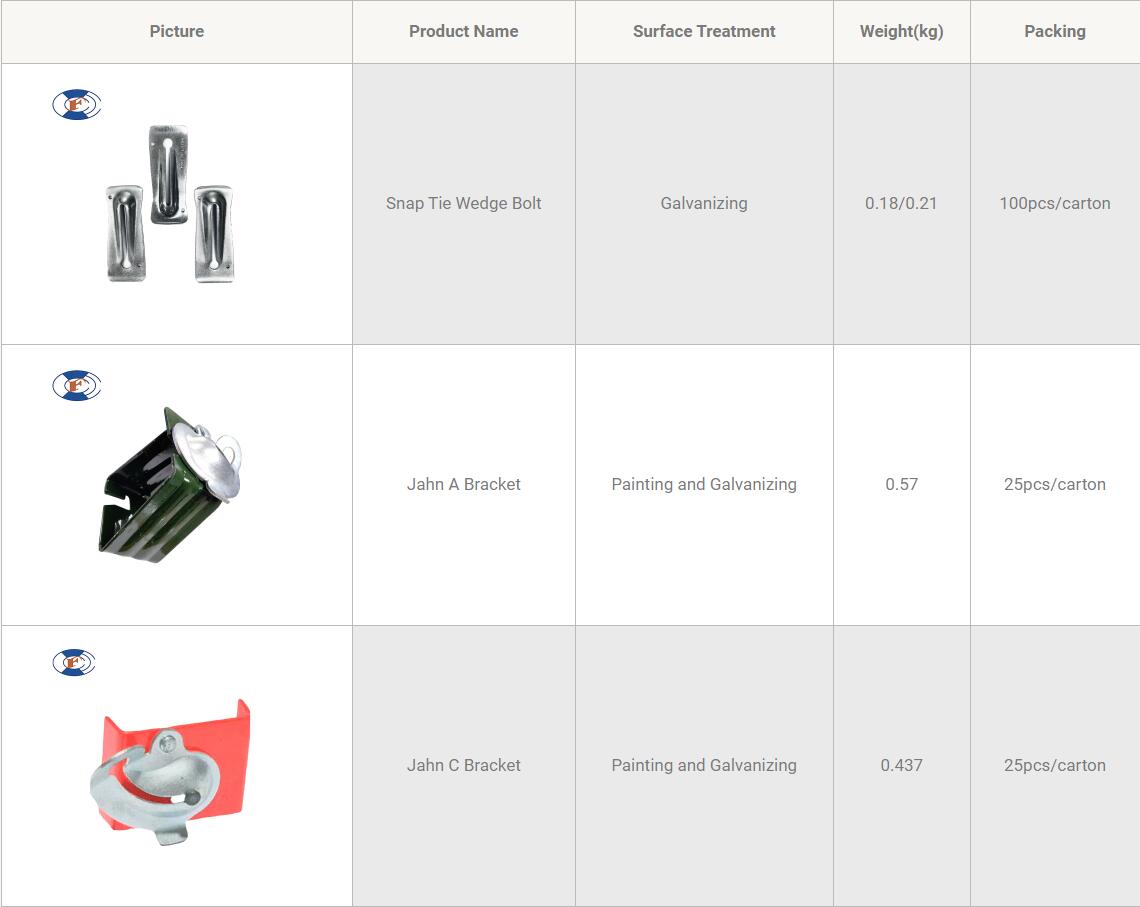

Concrete Snap Tie System

The concrete snap tie system is made up of several key components that work together to hold concrete forms in place while the concrete is poured and cures. Let’s dive into each product and see how they fit into the bigger picture.

ربطة عنق المفاجئة

ربطات العنق are the backbone of this system, keeping the form panels in place. There are two main types: short end snap ties and long end snap ties.

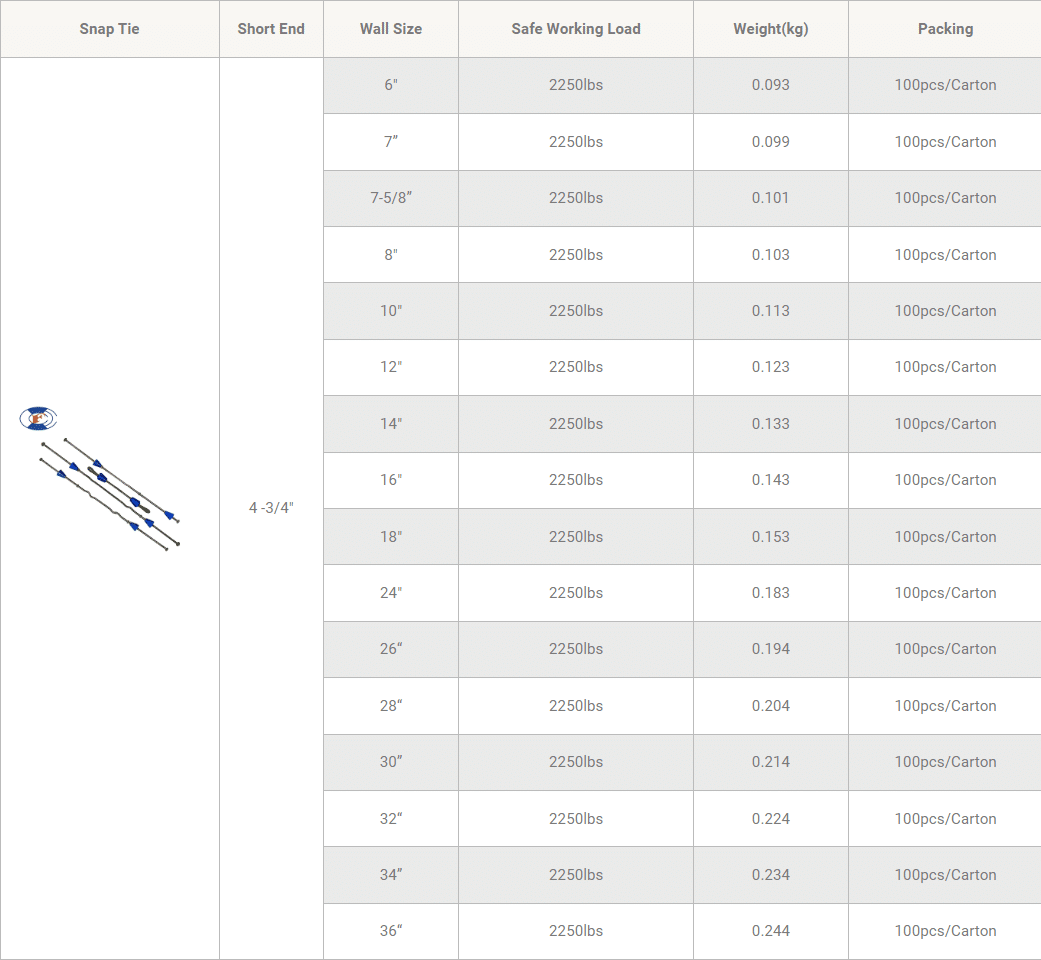

Short End Snap Tie

Short end snap ties are perfect for situations where the forms are closer together. They keep things stable and ensure that your wall thickness stays consistent.

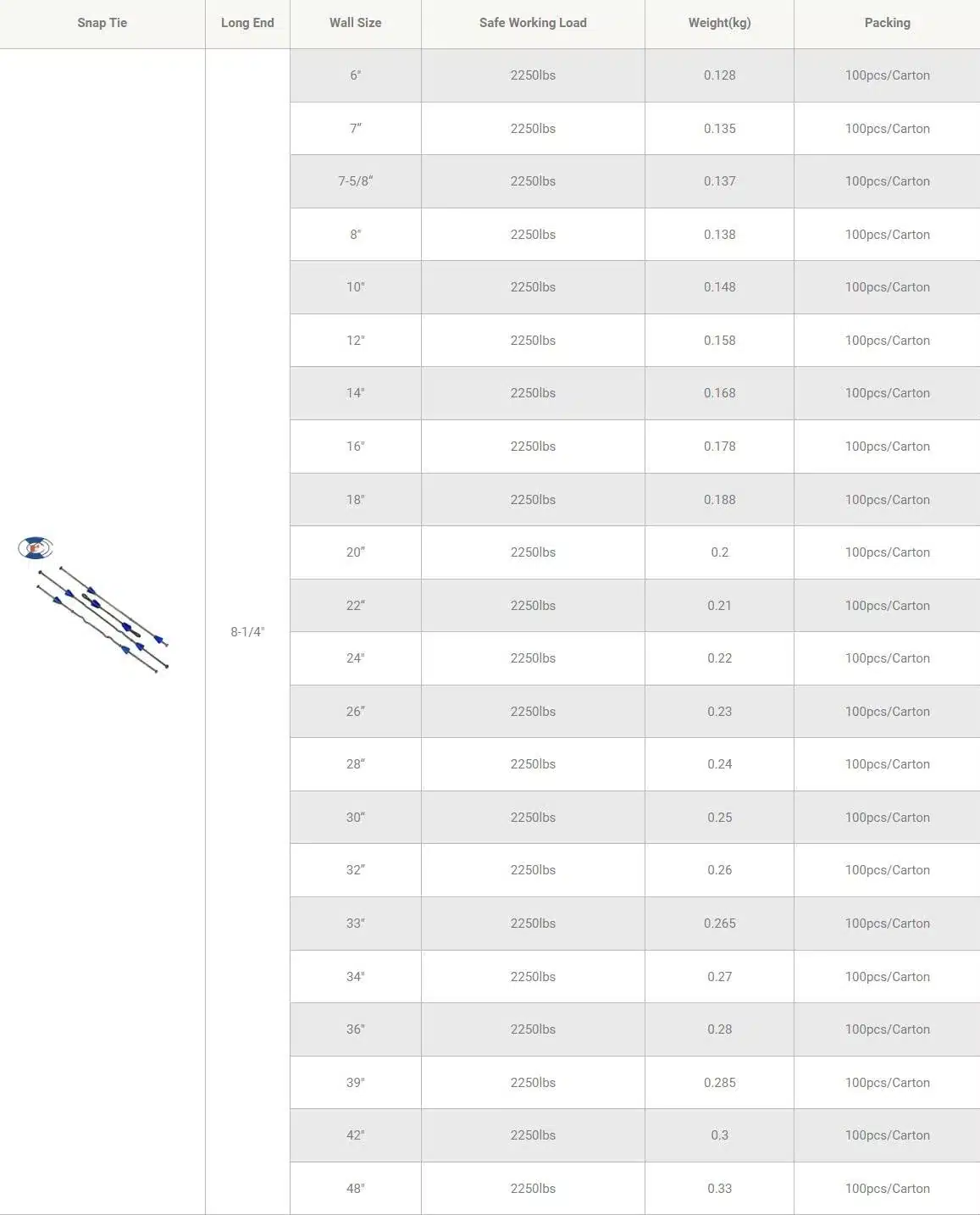

Long End Snap Tie

Long end snap ties come into play when the forms are set further apart. These longer ties bridge the gap and provide the necessary stability for thicker or larger walls.

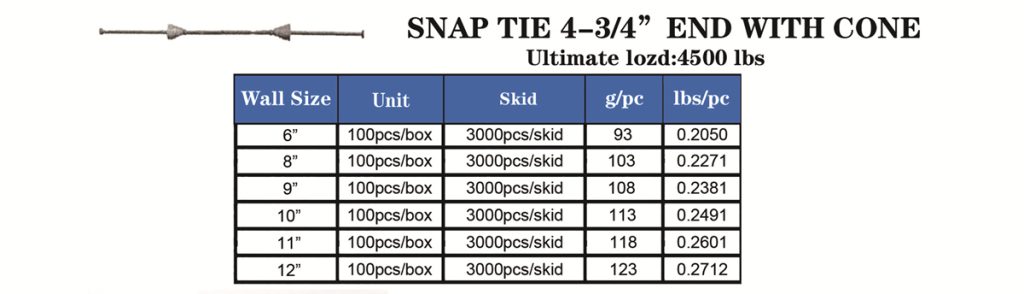

Snap Tie with Plastic Cone

رباطات بمخاريط بلاستيكية are designed to leave a clean hole in the concrete once the forms are removed. The plastic cone keeps concrete from seeping into the snap tie hole, resulting in a smooth, professional finish.

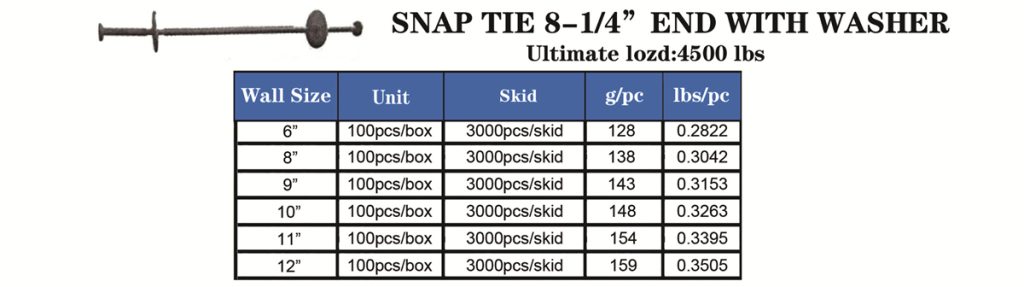

ربطة عنق مع غسالة

أربطة التثبيت مع الغسالات offer extra support and help distribute the load more evenly across the formwork. The washer prevents the tie from pulling through the form panel, adding an extra layer of stability.

Jahn A Bracket and Jahn C Bracket

قوس جان أ

إن Jahn A bracket secures the horizontal waler to the snap tie. It clamps onto the snap tie and offers strong support for the waler, ensuring your formwork stays aligned and steady during the pour.

قوس جان C

Similar to the Jahn A bracket, the Jahn C bracket secures vertical walers to the snap ties. It’s essential for keeping the forms vertically aligned and ensuring a straight, plumb wall.

إسفين ربطة عنق المفاجئة

أسافين ربطات العنق are used to lock snap ties in place. After inserting the snap ties through the form panels, you place the wedges over the ends and hammer them in, securing the ties and preventing movement during the pour.

Form Aligner Braces (Concrete Turnbuckle)

Form aligner braces, or concrete turnbuckles, are used to make sure the form panels are perfectly aligned. These adjustable braces allow for fine-tuning, which is crucial for achieving a smooth, level concrete surface.

One Piece Waler Clamp

إن one piece waler clamp secures the walers to the form panels. This single unit wraps around the waler and clamps onto the panel, providing a strong, secure connection that helps maintain form alignment and stability.

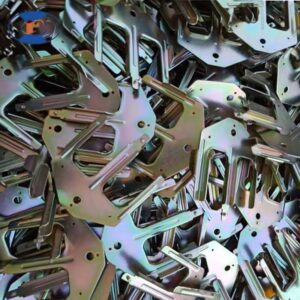

قوس والدر المزدوج

Double waler brackets are designed to support two horizontal walers on each side of the form panel, offering increased stability and strength. These brackets help maintain the structural integrity of the formwork by ensuring that the walers are firmly held in place, which is especially important for larger and taller walls. The double waler bracket helps to evenly distribute the pressure exerted by the wet concrete, preventing bulging or shifting of the form panels.

كيفية استخدام نماذج الربط المفاجئ

Using snap tie forms effectively involves several steps, each requiring careful attention to detail. Here’s a step-by-step guide to using snap tie forms with the products mentioned above.

Set Up Form Panels: Start by setting up the form panels to your desired dimensions. Make sure they are aligned and properly supported.

Insert Snap Ties: Insert the appropriate snap ties through the holes in the form panels. Use short end snap ties for closer panels and long end snap ties for wider panels.

Attach Plastic Cones or Washers: If using snap ties with plastic cones or washers, attach them to the ends of the snap ties. This ensures a clean finish and provides additional support.

Secure with Jahn Brackets: Use Jahn A brackets to secure the horizontal walers to the snap ties. Clamp the brackets onto the snap ties and tighten. For vertical walers, use Jahn C brackets similarly.

Install Snap Tie Wedges: Place snap tie wedges over the ends of the snap ties and hammer them into place. This locks the snap ties, preventing any movement during the pour.

Align Forms with Turnbuckles: Use form aligner braces (concrete turnbuckles) to adjust and fine-tune the alignment of the form panels. Ensure the panels are level and plumb.

Attach Waler Clamps: Use one piece waler clamps to secure the walers to the form panels. This adds additional stability and support to the formwork.

Install Double Waler Brackets: Place double waler brackets at regular intervals along the horizontal walers. These brackets support two walers on each side of the form panel, helping to maintain form alignment and distribute pressure evenly.

Final Inspection: Conduct a final inspection of the formwork to ensure all components are secure and the form panels are properly aligned.

Pour Concrete: With the formwork securely in place, proceed with pouring the concrete. Monitor the formwork during the pour to ensure it remains stable.

Cure and Remove Forms: Allow the concrete to cure as per the manufacturer’s instructions. Once cured, carefully remove the formwork. Snap ties with plastic cones or washers will leave a clean finish.

Conclusion About Use Snap Tie Forms

Using snap tie forms is a reliable method for creating stable, well-aligned concrete walls. By carefully selecting and using the appropriate products like snap ties, Jahn brackets, and form aligner braces, you can ensure your concrete forms are secure and the final structure is top-notch. Proper installation and alignment are crucial for the best results, so follow the steps outlined above for a successful concrete pour.

FAQs About Use Snap Tie Forms

What are snap tie forms used for?

Snap tie forms are used to hold concrete form panels in place during pouring and curing, ensuring the concrete wall is stable and properly shaped.

How do you choose between short end and long end snap ties?

Choose short end snap ties for form panels that are closer together and long end snap ties for wider panels to ensure stability and proper spacing.

Can snap ties be reused?

No, snap ties are typically single-use as they are embedded in the concrete and often need to be snapped off flush with the surface.

What is the purpose of the plastic cone on a snap tie?

The plastic cone on a snap tie prevents concrete from entering the hole left by the tie, ensuring a clean, professional finish on the concrete surface.

How do Jahn A brackets differ from Jahn C brackets?

Jahn A brackets are used for securing horizontal walers to snap ties, while Jahn C brackets are used for vertical walers, ensuring proper alignment and support.

What role do snap tie wedges play in the system?

Snap tie wedges are used to lock the snap ties in place, preventing them from moving during the concrete pour and ensuring the formwork remains stable.

Why are form aligner braces (turnbuckles) important?

Form aligner braces (turnbuckles) are important for fine-tuning the alignment of the form panels, ensuring they are level and plumb for a smooth concrete finish.

What is a one piece waler clamp used for?

A one piece waler clamp is used to secure the walers to the form panels, providing additional stability and support to the formwork.

How do double waler brackets contribute to form stability?

Double waler brackets support two horizontal walers on each side of the form panel, maintaining the alignment and stability of the form panels during the concrete pour by evenly distributing the pressure.

What should you check during the final inspection before pouring concrete?

During the final inspection, ensure all components are securely in place, the form panels are properly aligned, and there are no gaps or misalignments that could affect the concrete pour.