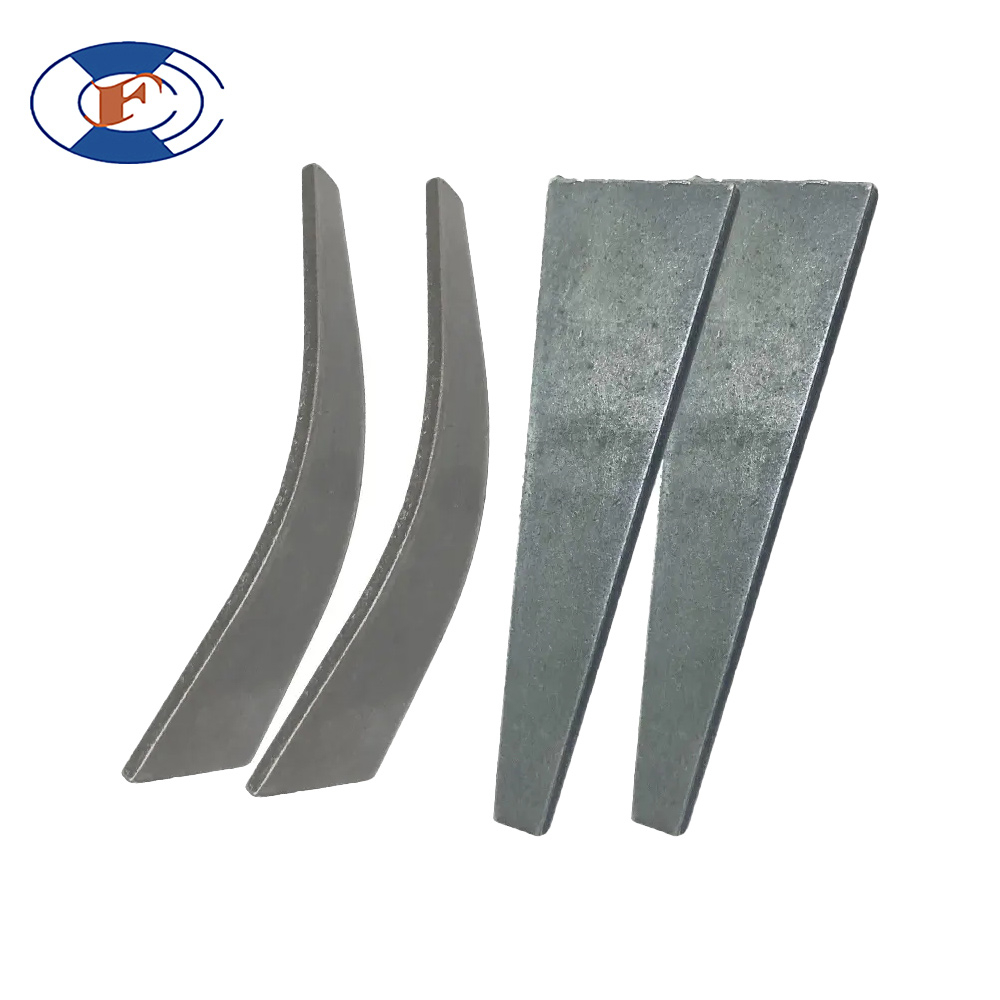

Forma do betonu Zakrzywiony klin Prosty klin

Zakrzywiony klin do betonu, w połączeniu z płaską opaską x, oferuje zaawansowane rozwiązanie do precyzyjnego wyrównywania betonu i podparcia w projektach budowlanych. Wykonane z wysokiej jakości, trwałych materiałów, kliny i opaski zapewniają wyjątkową wytrzymałość, trwałość i bezpieczne dopasowanie. Są skrupulatnie zaprojektowane zarówno pod kątem estetyki, jak i funkcjonalności, spełniając rygorystyczne testy kontroli jakości i posiadając odpowiednie certyfikaty. Ta linia produktów stanowi idealne połączenie innowacyjności i niezawodności w nowoczesnej technologii budowlanej.

W wymagającym świecie budownictwa dokładność i trwałość są najważniejsze. Wydajność szalunku betonowego w dużej mierze zależy od zastosowanych akcesoriów, a klin prosty i klin gięty stały się niezbędnymi narzędziami. Produkty te wyróżniają się dostarczaniem dopasowanych rozwiązań, które gwarantują precyzyjne wyrównanie i bezpieczny montaż. Podczas gdy oba kliny pełnią kluczowe role, każdy z nich posiada różne cechy, które pozwalają sprostać konkretnym wyzwaniom napotykanym w różnych środowiskach budowlanych. Niniejszy artykuł przedstawia dogłębną analizę klina prostego i klina zaginanego, szczegółowo opisując ich budowę, zastosowania i zalety, przy jednoczesnym zachowaniu najwyższych standardów jakości i obsługi klienta.

| Akcesoria do systemów formowania aluminium | ||||

|---|---|---|---|---|

| Zdjęcie | Pozycja | Rozmiar | Materiał | Cecha |

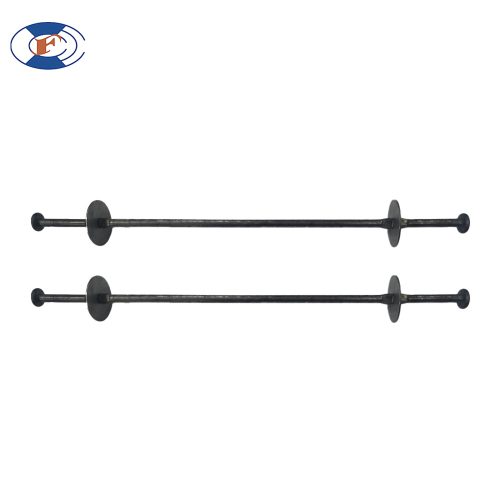

| Kołek z płaską główką | 71g | Stal #45 | Obróbka cieplna |

| Kołek z okrągłą główką | 103g | Stal #45 | Obróbka cieplna |

| Comobo Pin | 178g | Stal #45 | Obróbka cieplna |

| Klin prosty | 49.2g | Stal #45 | Obróbka cieplna |

| Zakrzywiony klin | 49.4g | Stal #45 | Obróbka cieplna |

Standardowa opaska płaska X

| Rozmiar | Jednostka | Paleta | Waga (kg) | Obciążenie maksymalne |

|---|---|---|---|---|

| 4" | 100szt/pudełko | 10000szt/paleta | 0.1040 | 6000 funtów |

| 6" | 100szt/pudełko | 10000szt/paleta | 0.1198 | 6000 funtów |

| 8" | 100szt/pudełko | 10000szt/paleta | 0.1412 | 6000 funtów |

| 10" | 100szt/pudełko | 10000szt/paleta | 0.1626 | 6000 funtów |

| 12" | 100szt/pudełko | 10000szt/paleta | 0.1840 | 6000 funtów |

| 14" | 100szt/pudełko | 5000szt/paleta | 0.2054 | 6000 funtów |

| 16" | 100szt/pudełko | 5000szt/paleta | 0.2268 | 6000 funtów |

| 18" | 50 sztuk/pakiet | 5000szt/paleta | 0.2482 | 6000 funtów |

| 20" | 50 sztuk/pakiet | 2500 sztuk/paleta | 0.2696 | 6000 funtów |

| 22" | 50 sztuk/pakiet | 2500 sztuk/paleta | 0.2910 | 6000 funtów |

Płaska opaska do dużych obciążeń X

| Rozmiar | Jednostka | Paleta | Waga (kg) | Obciążenie maksymalne (funty) |

|---|---|---|---|---|

| 4" | 100szt/pudełko | 10000szt/paleta | 0.1240 | 7000 |

| 6" | 100szt/pudełko | 10000szt/paleta | 0.1429 | 7000 |

| 8" | 100szt/pudełko | 10000szt/paleta | 0.1684 | 7000 |

| 10" | 100szt/pudełko | 10000szt/paleta | 0.1939 | 7000 |

| 12" | 100szt/pudełko | 10000szt/paleta | 0.2195 | 7000 |

| 14" | 100szt/pudełko | 5000szt/paleta | 0.2450 | 7000 |

| 16" | 100szt/pudełko | 5000szt/paleta | 0.2705 | 7000 |

| 18" | 50 sztuk/pakiet | 5000szt/paleta | 0.2960 | 7000 |

| 20" | 50 sztuk/pakiet | 2500 sztuk/paleta | 0.3215 | 7000 |

| 22" | 50 sztuk/pakiet | 2500 sztuk/paleta | 0.3470 | 7000 |

Przegląd klinów prostych

Klin prosty służy jako kamień węgielny zapewniający jednolitość i stabilność w systemach szalunków betonowych. Wykonany ze stali stopowej o wysokiej wytrzymałości na rozciąganie, oferuje niezrównaną sztywność i nośność, dzięki czemu idealnie nadaje się do utrzymania idealnie wyrównanej konstrukcji. Konstrukcja podkreśla prostotę i funkcjonalność; jej płaska powierzchnia i precyzyjne kąty równomiernie rozkładają nacisk na szalunek. Ta cecha minimalizuje odkształcenia i zapewnia bezpieczne dopasowanie między komponentami, nawet w scenariuszach wysokiego ciśnienia. Środki kontroli jakości i standardy certyfikacji potwierdzają zdolność Straight Wedge do zapewnienia stałej wydajności, zapewniając, że spełnia on rygorystyczne wymagania nowoczesnych projektów budowlanych. Prosta, ale solidna konstrukcja pozwala zarówno na standardowe, jak i niestandardowe konfiguracje, zapewniając elastyczność w celu spełnienia wymagań specyficznych dla projektu bez uszczerbku dla jakości.

Przegląd klina zginającego

W przeciwieństwie do swojego prostego odpowiednika, Bend Wedge oferuje innowacyjne rozwiązanie dla systemów szalunkowych, które wymagają regulacji kątowej i dynamicznego pozycjonowania. Zaprojektowany z subtelnie zakrzywionym profilem, Bend Wedge zaspokaja potrzebę nieliniowego wyrównania w złożonych konstrukcjach. Jego konstrukcja wykorzystuje zaawansowane materiały kompozytowe w połączeniu z wysokowytrzymałą stalą stopową, osiągając delikatną równowagę między elastycznością a trwałością. Taka konstrukcja zapewnia, że klin może dostosowywać się do różnych kątów przy jednoczesnym zachowaniu integralności szalunku. Skrupulatny proces inżynieryjny klina Bend Wedge obejmuje precyzyjną kalibrację jego krzywizny w celu efektywnego rozłożenia naprężeń, zapewniając, że proces wiązania betonu pozostaje niezakłócony. Certyfikacja przez agencje kontroli jakości podkreśla jego niezawodność, czyniąc go zaufanym wyborem dla projektów, w których zdolność adaptacji i precyzja są zbieżne.

Skład materiału i certyfikacja

Podstawą klina prostego Concrete Bend Wedge jest stal stopowa o wysokiej wytrzymałości na rozciąganie, która zapewnia wyjątkową wytrzymałość i odporność. Producenci wykorzystują materiały, które są odporne na korozję i wytrzymują znaczne naprężenia, zapewniając, że klin zachowuje swoją integralność strukturalną przez długi czas. Uzupełnieniem tego jest opaska x-flat z zaawansowanymi elementami kompozytowymi, które zapewniają równowagę między elastycznością a sztywnością. Ten przemyślany dobór materiałów nie tylko przyczynia się do długowieczności systemu, ale także zapewnia, że każdy element spełnia rygorystyczne testy kontroli jakości. Certyfikacja przez uznane międzynarodowe agencje dodatkowo potwierdza niezawodność i bezpieczeństwo tych produktów, wzmacniając zaufanie do ich wydajności w różnych warunkach budowlanych.

Specyfikacje techniczne i zastosowania

Precyzja definiuje konstrukcję prostego klina Concrete Bend Wedge. Dzięki starannie zaprojektowanym wymiarom i tolerancjom, klin ułatwia dokładne rozłożenie obciążenia na szalunek, zapobiegając w ten sposób niewspółosiowości i odkształceniom strukturalnym podczas procesu utwardzania betonu. Opaska x-flat, zaprojektowana z myślą o płynnej integracji z klinem, zapewnia bezpieczne połączenie, które minimalizuje ryzyko poślizgu lub niewspółosiowości. Para ta znajduje zastosowanie w różnych projektach, od montażu prefabrykowanych elementów betonowych po rozległe projekty infrastrukturalne. Parametry produktu, w tym dokładność wymiarowa, nośność i charakterystyka obciążenia, zostały skrupulatnie zoptymalizowane w oparciu o dokładne testy terenowe i analizy inżynieryjne. Każda jednostka jest poddawana rygorystycznym ocenom jakości, co zapewnia, że akcesoria konsekwentnie działają w trudnych warunkach typowych dla nowoczesnych środowisk budowlanych.

Innowacje projektowe i zapewnienie jakości

Innowacje napędzają ciągłe doskonalenie systemu klinów i opasek. Inżynierowie wykorzystują zaawansowane techniki projektowania wspomaganego komputerowo, aby dopracować każdy szczegół, zapewniając, że komponenty zapewniają zarówno wydajność, jak i łatwość użytkowania. Proces produkcyjny obejmuje precyzyjną obróbkę skrawaniem i nowoczesne metody wytwarzania, które pozwalają na spójną replikację precyzyjnie dostrojonych specyfikacji. W ten sposób system nie tylko spełnia, ale często przekracza oczekiwania profesjonalistów z branży budowlanej. Nacisk na zapewnienie jakości jest widoczny na każdym etapie produkcji, od wyboru materiałów po końcową kontrolę. Każdy produkt przechodzi przez kompleksowe fazy testowania, które oceniają zarówno jego właściwości fizyczne, jak i mechaniczne, czego zwieńczeniem są akcesoria, które ucieleśniają zarówno solidną konstrukcję, jak i skrupulatne wykonanie.

Partnerstwo i doskonałość usług

Poza technicznymi zaletami prostego klina Concrete Bend Wedge i opaski x-flat, korzyści wynikające ze współpracy zapewniane przez H&F stanowią znaczącą wartość dodaną dla kupujących. Decydując się na współpracę z H&F, klienci uzyskują dostęp do bezpłatnych próbek, które pozwalają na praktyczną ocenę działania produktu przed podjęciem decyzji na pełną skalę. Indywidualna obsługa klienta zapewnia, że każde zapytanie jest traktowane z fachową uwagą, zapewniając niestandardowe rozwiązania, które spełniają określone wymagania projektu. Ponadto usługa dostawy "od drzwi do drzwi" podkreśla zaangażowanie w wydajność i niezawodność, usprawniając proces zaopatrzenia i zapewniając, że materiały dotrą szybko i bezpiecznie. Zalety te sprawiają, że H&F jest zaufanym partnerem na konkurencyjnym rynku akcesoriów do form betonowych i osprzętu do olinowania, oferującym połączenie wiedzy technicznej i wyjątkowej obsługi.

Klin prosty Concrete Bend Wedge, w połączeniu z pasującą opaską x-flat, stanowi przemyślane rozwiązanie zwiększające wydajność systemów szalunków betonowych. Szczegółowa dbałość o jakość materiałów, precyzyjna inżynieria i rygorystyczna kontrola jakości skutkują produktem, na którym profesjonaliści budowlani mogą polegać nawet w najbardziej wymagających okolicznościach. Dzięki połączeniu najnowocześniejszej konstrukcji z zaangażowaniem w zadowolenie klienta, system ten nie tylko spełnia, ale często przewyższa oczekiwania użytkowników. Koncentrując się na rzeczywistych zastosowaniach i głębokim zrozumieniu dynamiki konstrukcji, akcesoria te stanowią nieoceniony wkład w projekty budowlane, które wymagają precyzji i trwałości.

Co nas wyróżnia

1. Dedykowana, całodobowa obsługa klienta jeden na jednego

Nasz zespół jest dostępny przez całą dobę, aby zapewnić spersonalizowane wsparcie i szybko odpowiedzieć na wszelkie pytania lub wątpliwości, zapewniając płynne i niezawodne działanie.

2. Szeroki asortyment, konkurencyjne ceny i bezpłatne próbki

Utrzymujemy solidne stany magazynowe, aby zapewnić szybką i niezawodną realizację zamówień. Nasze konkurencyjne ceny i bezpłatne próbki pozwalają ocenić jakość z pierwszej ręki, zapewniając terminową i niezawodną dostawę w ramach każdego cyklu projektu.

3. Rygorystyczna kontrola jakości i kompleksowe raporty z inspekcji

Nasz rygorystyczny proces kontroli jakości gwarantuje, że wszystkie produkty spełniają najwyższe standardy. Każde zamówienie jest poparte szczegółowymi raportami z testów, co zapewnia spokój ducha i stałą jakość.

4. Certyfikowana doskonałość: CE i więcej dla niezawodnego partnerstwa

Podobne produkty

-

Snap Tie Wedge

$1.00