Concrete forming pins, often referred to as forming stakes or steel stakes, are essential tools in the construction industry. These pins are used to secure and stabilize concrete forms, ensuring that the forms stay in place while the concrete sets. They come in various types and materials, each designed to meet specific construction needs. Understanding the different types of concrete forming pins and their applications is crucial for achieving a strong and stable concrete structure.

The Type of Concrete Forming Pins

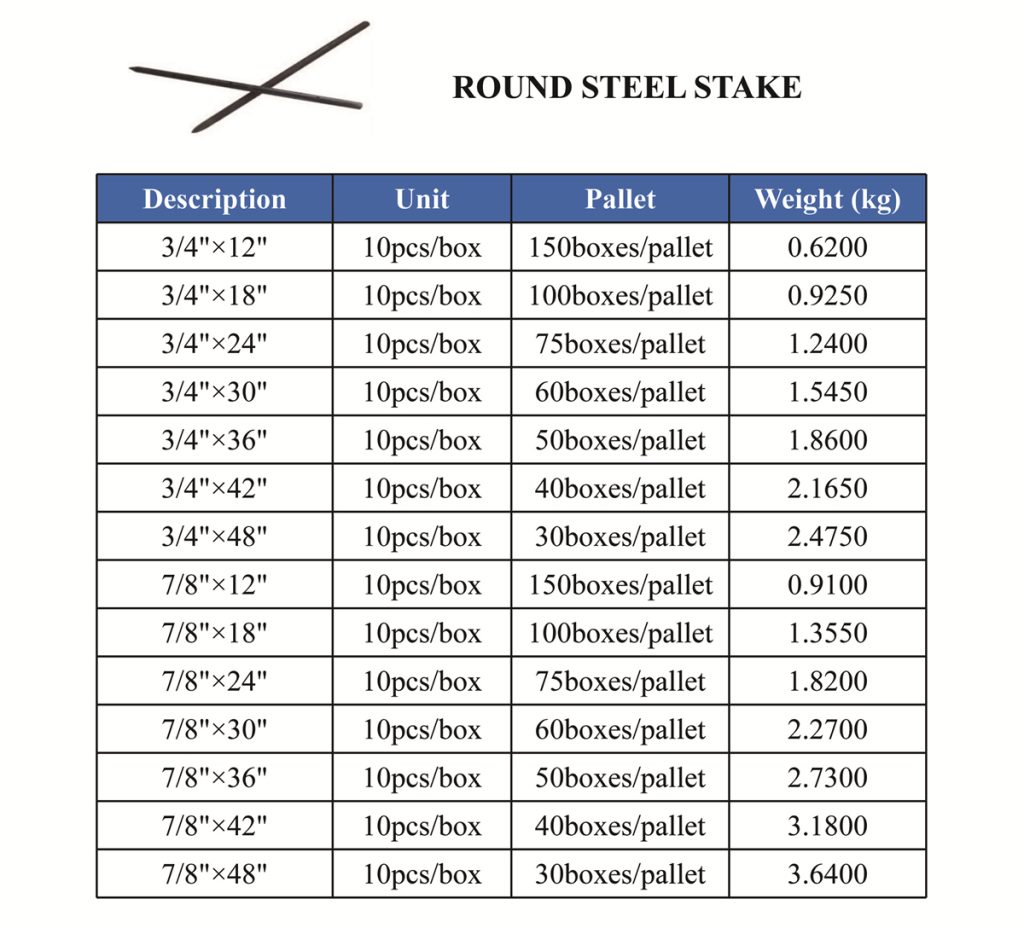

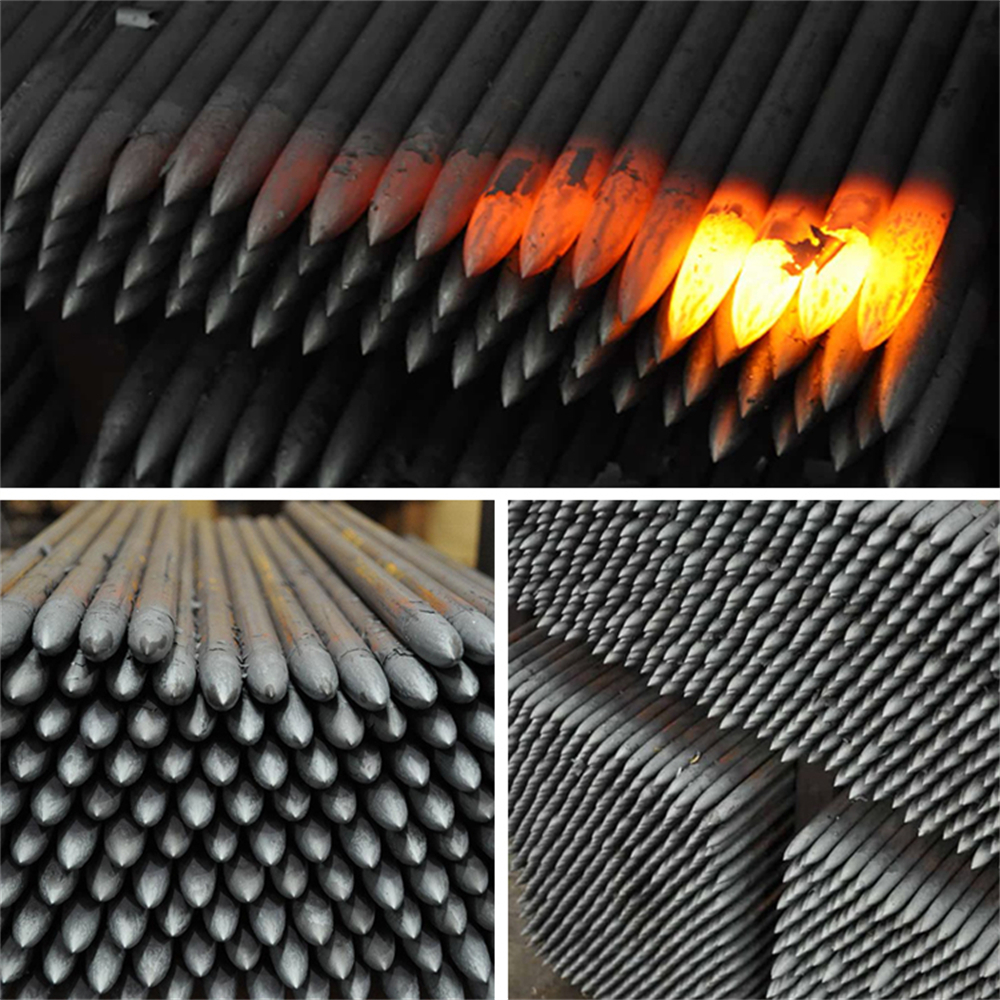

Round Steel Stake

Round steel stakes are among the most common types of concrete forming pins. They are cylindrical in shape, making them easy to drive into the ground. These stakes are often used for lightweight forms and temporary structures. Their smooth surface ensures minimal disruption to the surrounding material, and they are typically made from durable, galvanized steel to resist rust and corrosion.

Square Steel Stake

Square steel stakes, as the name suggests, have a square cross-section. This design provides added stability and prevents the stake from rotating in the ground, making it ideal for heavier forms and more permanent structures. Square steel stakes are also made from high-strength steel, ensuring they can withstand the pressure from the concrete without bending or breaking.

I-Beam Stake

I-beam stakes are designed for heavy-duty applications where maximum strength is required. Their unique I-shaped cross-section provides exceptional resistance to bending and deformation, making them suitable for large-scale construction projects. These stakes are often used in conjunction with larger forms or when working with high-pressure concrete pours.

Flat Steel Stake

Flat steel stakes are flat and thin, making them easy to insert into the ground and ideal for applications where space is limited. Despite their slim profile, flat steel stakes offer significant holding power and are commonly used for securing thin or delicate forms. They are typically made from high-grade steel and are often coated to protect against rust.

What is a Concrete Pin Used For?

Concrete pins are primarily used to secure and stabilize concrete forms during the pouring and setting process. By anchoring the forms in place, these pins prevent shifting or movement that could lead to uneven or misshapen concrete structures. In addition to securing forms, concrete pins can also be used to anchor other construction materials, such as rebar, wood, or mesh, ensuring that all elements of the structure remain in the correct position during construction.

How Do You Fasten Concrete Forms?

Fastening concrete forms typically involves a combination of forming pins, braces, and ties. The process begins by placing the forms in the desired position and securing them with forming pins driven into the ground at regular intervals. These pins hold the forms steady and prevent them from moving while the concrete is poured. In some cases, additional braces or ties may be used to further stabilize the forms, especially in areas where the ground is uneven or the concrete pour is particularly large. Once the concrete has been poured and has begun to set, the forms can be removed, leaving behind a perfectly shaped structure.

Conclusion About Concrete Forming Pins

Concrete forming pins are an essential component in ensuring the stability and precision of concrete structures. Whether you’re working on a small residential project or a large commercial build, selecting the right type of forming pin is critical to the success of the project. At Qingdao H&F, we specialize in providing high-quality concrete forming pins that meet the specific needs of your construction project. We guarantee a stable delivery cycle, carry out thorough quality inspections before every delivery, and provide detailed inspection reports to ensure the highest standards of quality and speed. Our one-to-one customer service ensures that a dedicated specialist will be with you every step of the way, providing the most professional and high-quality service available.

FAQ About Concrete Forming Pins

What is the difference between round and square steel stakes?

Round steel stakes are easier to drive into the ground and are ideal for lightweight forms, while square steel stakes offer greater stability and are better suited for heavier forms.

Can concrete forming pins be reused?

Yes, concrete forming pins made from high-quality steel can often be reused multiple times, provided they are properly cleaned and maintained after each use.

How do I choose the right size of concrete forming pin?

The size of the forming pin should be based on the size and weight of the forms you are using. Larger, heavier forms require longer and thicker pins for adequate support.

What materials are concrete forming pins made from?

Concrete forming pins are typically made from steel, which is durable and resistant to bending under pressure. Some may also be coated with protective materials to prevent rust.

How deep should concrete forming pins be driven into the ground?

Concrete forming pins should be driven deep enough into the ground to securely anchor the forms, usually about two-thirds of the pin’s length.

Can I use concrete forming pins on rocky or uneven ground?

Yes, but it may require additional effort or specialized tools to drive the pins into rocky or uneven ground. In such cases, longer or more robust pins may be necessary.

How do I remove concrete forming pins after the concrete has set?

Concrete forming pins can be removed by gently tapping them with a hammer or using a specialized tool designed to grip and pull the pin from the ground.

What is the lifespan of a concrete forming pin?

The lifespan of a concrete forming pin depends on the material and how often it is used, but high-quality steel pins can last for many years with proper care.

Are there any alternatives to concrete forming pins?

Alternatives to concrete forming pins include wooden stakes or plastic anchors, though these are generally less durable and not suitable for heavy-duty applications.

What safety precautions should I take when using concrete forming pins?

Always wear protective gear, such as gloves and safety glasses, when driving or removing concrete forming pins to prevent injury. Ensure the ground is stable before placing the pins to avoid accidents.