Lifting Anchor

-

Wire Rope Lifting Loop

$1.00 -

Hook Lift Anchor

$1.00 -

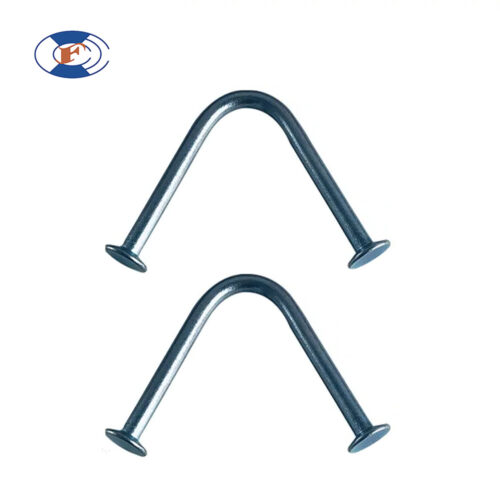

Crown Foot Anchor

$1.00

Precast concrete is fundamental to modern construction, yet safely handling these hefty components demands specialized equipment. Enter lifting anchors – the essential connection between precast concrete and lifting gear.

Here are the main players in the lifting anchor arena:

lifting Anchor

Lifting anchor, often referred to as a dog bone, is crucial in construction for handling precast concrete elements. Made from high-strength steel, its unique shape ensures a secure grip with lifting mechanisms. During concrete casting, the anchor is embedded into the element, becoming an integral part of it. This precise placement ensures even weight distribution during lifting, preventing damage such as cracking.

After the concrete cures, the lifting anchor provides a reliable attachment point for lifting clutches or hooks. These devices securely engage with the anchor, enabling cranes or other machinery to lift and maneuver the concrete element safely. The dog bone design ensures a stable connection, minimizing the risk of slippage.

Beyond load transfer and secure connection, lifting anchors also help control the orientation of concrete elements during lifting. Strategic placement of anchors allows for balanced lifting, making positioning easier. Designed for repeated use, these anchors offer a cost-effective solution that enhances safety and efficiency on construction sites.

Installing lifting anchors involves securing them in the mold using reinforcing bars or recess formers to keep them in place during the concrete pour. This ensures that, once the concrete sets and formwork is removed, the lifting process can proceed smoothly.

Lifting Clutch

A lifting clutch is a specialized mechanical device crucial in the construction and engineering industries for the safe and efficient handling of precast concrete elements. When used in conjunction with a lifting anchor system, it ensures that heavy loads can be lifted and transported securely, which is essential for maintaining the integrity and safety of concrete structures during these operations.

The lifting clutch functions by connecting lifting equipment, such as cranes or hoists, to the lifting anchors embedded in concrete elements. These anchors are pre-installed metal components designed to provide robust lifting points. The clutch attaches to the anchor through a mechanical interlock, which ensures a secure connection that can only be disengaged when there is no load. This safety feature prevents accidental releases during lifting, which could lead to severe accidents or damage.

Once attached, the lifting clutch ensures that the load is distributed evenly through the lifting anchor and the concrete element. This even distribution minimizes stress concentrations within the concrete, reducing the risk of cracks or structural damage. The lifting process then proceeds with the lifting equipment raising the concrete element, supported securely by the clutch-anchor system. After the element is placed in its intended position and the load is transferred to the structure or ground, the lifting clutch can be easily released, thanks to modern quick-release mechanisms.

Lifting clutches and anchor systems are particularly valuable in various construction applications. In the precast concrete industry, they are used to handle wall panels, beams, columns, and other elements. Infrastructure projects, such as bridges and tunnels, rely on these systems for moving large concrete components. Building construction also benefits from lifting clutches, especially in erecting multi-story buildings where precision placement of large panels is required.

The advantages of using lifting clutches are numerous. They significantly enhance safety by preventing accidental load releases. Their efficiency in allowing quick attachment and detachment speeds up construction processes and reduces labor costs. Additionally, lifting clutches are versatile, available in different sizes and load capacities to meet various project needs, and are built from durable materials to withstand the harsh conditions of construction sites.

Lifting Pin Eye

The lifting pin eye is a crucial component in the construction and engineering sectors, designed to facilitate the safe and efficient handling of heavy precast concrete elements. Integrated into lifting anchor systems, it provides a reliable attachment point for lifting equipment, ensuring stability and safety during transport and installation.

The lifting pin eye is typically made of high-strength steel and features a rounded eye or loop through which lifting hooks or shackles can be connected. This robust design allows it to withstand substantial loads and harsh construction environments. The pin eye is embedded into the concrete element, forming a secure anchor point that can be easily accessed during lifting operations.

In operation, the lifting pin eye works by offering a strong, reliable point for lifting equipment to connect to. Once the lifting hook or shackle is attached to the eye, the load can be lifted smoothly. This connection ensures an even distribution of the load, reducing the risk of damage to the concrete element. The pin eye’s design prevents lateral movements that could destabilize the load, enhancing the overall safety of the lifting process.

The use of lifting pin eyes is prevalent in various applications. In the precast concrete industry, they are essential for lifting wall panels, beams, columns, and other prefabricated elements. Infrastructure projects such as bridges and tunnels rely on lifting pin eyes for moving large concrete components safely. Additionally, they are used in building construction, particularly for multi-story structures where precision and safety are paramount.

One of the key benefits of using lifting pin eyes is their simplicity and reliability. Their straightforward design allows for quick attachment and detachment, which speeds up construction processes and reduces labor costs. Furthermore, lifting pin eyes are highly versatile, available in different sizes and load capacities to meet diverse project requirements. Their durability ensures long-term performance, even under the most demanding conditions.

Utility Lifting Anchor

The utility lifting anchor is a critical component in the construction and engineering sectors, designed to facilitate the safe and efficient handling of heavy precast concrete elements. These anchors ensure the secure lifting, transport, and precise placement of concrete components, which is vital for maintaining their structural integrity throughout various construction stages.

Constructed from high-strength steel, utility lifting anchors are embedded into concrete elements during the casting process. This embedding provides a robust lifting point capable of withstanding the substantial forces involved in moving heavy loads. The anchors come in various designs, including spherical head anchors and flat anchors, each tailored to specific lifting requirements and load capacities.

The use of a utility lifting anchor begins with its embedding in the concrete. During casting, the anchor is placed in the desired location within the concrete element. Once the concrete has set, the anchor provides a solid and secure lifting point. When the element is ready to be moved, a lifting device such as a lifting clutch or hook is attached to the anchor. This connection is designed to be secure, ensuring that the lifting device does not accidentally disengage during the lifting process.

With the lifting equipment attached, the concrete element can be safely lifted and transported to its intended location. The design of the utility lifting anchor ensures that the load is distributed evenly, minimizing the risk of damage to the concrete and enhancing overall safety. After the concrete element is positioned and the load is supported by the structure or ground, the lifting equipment can be detached from the anchor. The anchor remains embedded in the concrete, often allowing for future lifts if necessary.

Utility lifting anchors are essential in a wide range of applications. In the precast concrete industry, they are used for lifting and placing wall panels, beams, and columns. Infrastructure projects such as bridges and tunnels also rely on these anchors to handle large concrete components. In building construction, particularly in multi-story structures, utility lifting anchors ensure the precise placement of large panels, which is crucial for structural stability and safety.

The advantages of utility lifting anchors are numerous. They significantly enhance safety by providing reliable lifting points that prevent accidental releases. Their efficiency allows for quick and secure attachment and detachment, which speeds up construction processes and reduces labor costs. Moreover, these anchors are highly versatile, available in various sizes and capacities to meet different project needs. Their durable construction ensures long-term performance, even under the demanding conditions of construction environments.

Forged Erection Anchor

The forged erection anchor is an indispensable component in the construction and engineering industries, designed to facilitate the safe and efficient handling of heavy precast concrete elements. Integral to lifting and anchoring systems, these anchors ensure the secure transport, positioning, and installation of concrete components, which is crucial for maintaining structural integrity and safety during various construction stages.

Forged erection anchors are manufactured from high-strength steel, ensuring durability and robustness. The forging process enhances the anchor’s mechanical properties, providing superior strength and resistance to wear and fatigue. These anchors are typically embedded into concrete elements during the casting process, forming a reliable lifting point capable of withstanding substantial loads.

The use of a forged erection anchor begins with its integration into the concrete during casting. The anchor is strategically placed in the mold before the concrete is poured. Once the concrete sets, the anchor becomes an integral part of the element, providing a secure point for attachment. When the concrete element is ready to be moved, lifting equipment, such as cranes equipped with appropriate lifting devices, is connected to the anchor. The secure design of the forged erection anchor ensures a firm attachment, preventing accidental disengagement during lifting.

During lifting operations, the forged erection anchor allows for the smooth and controlled movement of concrete elements. The anchor’s design ensures even load distribution, minimizing stress concentrations within the concrete and reducing the risk of structural damage. After the concrete element is positioned and the load is transferred to the supporting structure, the lifting equipment can be easily detached from the anchor. The anchor remains embedded in the concrete, providing ongoing structural support and potential for future lifting if necessary.

Forged erection anchors are widely used in various construction applications. In the precast concrete industry, they are essential for handling wall panels, beams, and columns. Infrastructure projects, such as bridges and tunnels, rely on these anchors for safely moving large concrete components. In building construction, especially for multi-story buildings, forged erection anchors are crucial for the precise placement of large panels and other structural elements.

The advantages of forged erection anchors are significant. Their robust construction enhances safety by ensuring reliable lifting points that prevent accidental releases. They contribute to construction efficiency by enabling quick and secure attachment and detachment, thereby accelerating project timelines and reducing labor costs. Furthermore, these anchors are versatile, available in various sizes and capacities to meet diverse project requirements. Their durability ensures they can withstand the harsh conditions of construction environments, providing long-term performance and reliability.