Concrete Snap Ties plywood

High strength & durable snap tie manufacturer & Supplier. Support customization. 6-48 inch long end short end snap ties concrete with plastic cone.

Snap ties are a fundamental component in concrete formwork, particularly valued for their role in maintaining even spacing between wall forms during concrete pours. Designed to keep formwork stable while concrete sets, snap ties prevent bulging and misalignment in concrete walls. This stability is crucial in ensuring that the concrete sets correctly, reducing potential cracking and structural weaknesses.

Concrete Snap Tie with Plastic Cone

Short End Snap Ties

Short end snap ties are shorter in length and are most ordinarily used for lighter applications with less protrusion above the concrete surface. They are multi-purpose and are normally utilized in applications like wall forming, slab forming, and forming small concrete structures.

Long End Snap Ties

Long end snap ties have a longer length and offer greater strength and support, ideal for heavy-duty projects with thicker formwork. They are best in large-scale projects such as high-rise buildings, deep foundations, and large infrastructure constructions where more length and firm support are needed.

Concrete Snap Tie with Washer

4-3/4‘’ snap tie with washer

8-1/4‘’ snap tie with washer

Concrete Snap Ties with Washers are another essential component in the realm of concrete formwork in the United States. They differ from the plastic cone snap ties in a few significant ways:

Washer: In this type of snap tie, a washer is used to secure the formwork. The washer acts as a plate that holds the snap tie in place, providing extra stability.

Snap Tie Wedge & Jahn A bracket Jahn C Bracket

Snap Tie Wedge: A snap tie wedge is a simple but essential element that enables the connection of the snap tie and the form panel. It is typically taper in shape and enables easy removal and insertion. This wedge creates a secure connection between the snap tie and the form panel, thereby inhibiting panel movement during the pouring of the concrete.

Jahn A Bracket: The Jahn A bracket is a special formwork accessory that gives extra support and alignment to the form panels, especially at junctions and corners. The Jahn A bracket is usually metallic in nature and is of a special shape that enables it to be fixed easily to the form panels. The Jahn A bracket assists in keeping the required form and size of the concrete structure and also in giving a quality finish.

Jahn C Bracket: In a way similar to the Jahn A bracket, the Jahn C bracket is another category of formwork accessory used in supporting and guiding. However, the structure of the Jahn C bracket targets specific applications such as supporting formwork vertical panels or the manufacture of curved and angled structures. Its unique profile and configuration as compared to that of the Jahn A bracket make it more suitable for being applied to numerous construction situations.

| Product | Product Name | Surface Treatment | Weight(kg) | Packing |

|---|---|---|---|---|

| Snap Tie Wedge Bolt | Galvanizing | 0.18/0.21 | 100pcs/carton |

| Jahn A Bracket | Painting and Galvanizing | 0.57 | 25pcs/carton |

| Jahn C Bracket | Painting and Galvanizing | 0.437 | 25pcs/carton |

Washer vs. Plastic Cone

Snap Tie with Plastic Cone

- Design & Function:

The plastic cone is engineered to snap off cleanly once the concrete has set. This ensures that very little material is left embedded in the concrete, promoting a neat finish. - Material Benefits:

Made from durable plastic, these ties resist corrosion and reduce the risk of spalling, which is especially beneficial in aggressive environments or where aesthetics are important. - Installation & Performance:

The break-away design allows for quicker, cleaner installation and reduces the need for post-pour clean-up. The plastic element minimizes disruptions in the concrete matrix.

Snap Tie with Washer

- Design & Function:

In this variant, a metal washer is integrated into the tie. The washer remains embedded in the concrete and helps distribute loads more evenly across the rebar, ensuring robust stabilization. - Material Considerations:

Although the metal washer offers excellent mechanical strength, it can be more susceptible to corrosion if not properly treated. This might be a concern in moisture-prone or chemically aggressive environments. - Installation & Performance:

The presence of a metal washer can provide a stronger, more secure connection during the concrete pour, but it may require extra attention during installation to prevent issues like concrete blemishes or potential interference with the finish.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

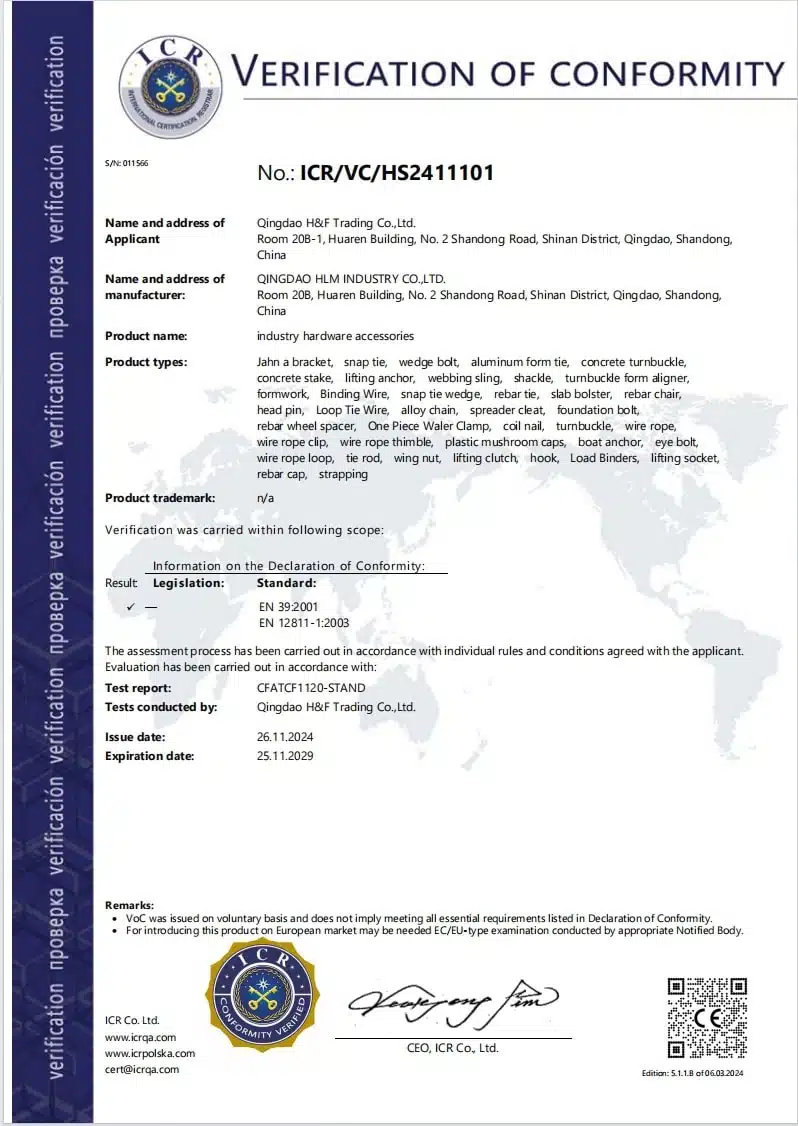

4. Certified Excellence: CE and More for Reliable Partnerships

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Related products

-

Standard Wedge Bolt

$0.01