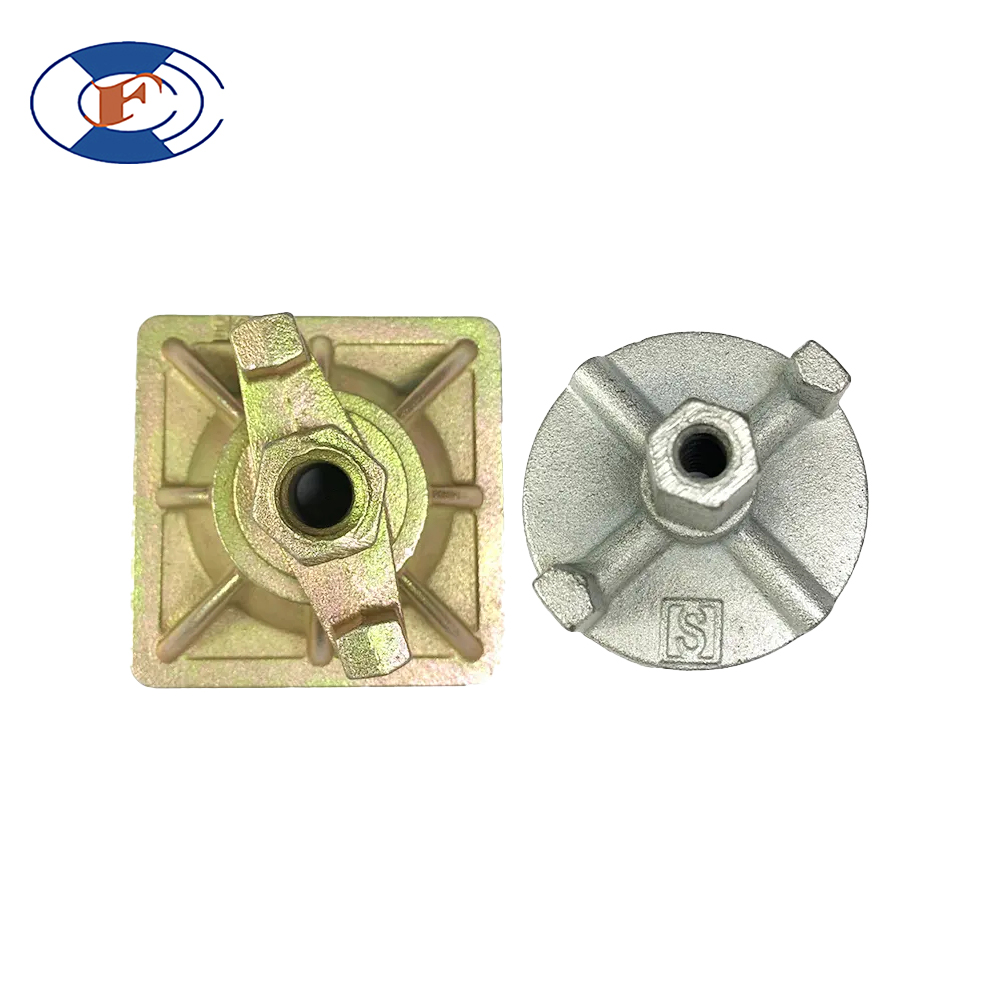

Schalungsanker-Mutter

Schalungsanker-Muttern sind im Betonbau unverzichtbar und gewährleisten die Stabilität und Ausrichtung von Schalungssystemen. Als Handelsunternehmen mit 20 Jahren Erfahrung bietet Qingdao H&F qualitativ hochwertige Ankermuttern an, die mit verschiedenen Zugstangensystemen kompatibel sind, darunter Fugenbänder und Flügelmuttern. Wir kümmern uns um die Belange unserer Kunden, indem wir einen persönlichen Kundenservice, schnelle Lieferzyklen und detaillierte Qualitätsprüfungsberichte anbieten, um sicherzustellen, dass jedes Produkt den strengen Standards entspricht.

Das Rückgrat der Stabilität von Betonschalungen

In der anspruchsvollen Welt des Betonbaus sind Stabilität und Präzision während des Schalungsprozesses nicht verhandelbar. Das Herzstück dieses Prozesses ist das Ankerstabsystem, eine umfassende Lösung, die Ankerstäbe, Ankermuttern, Wassersperren und Flügelmuttern umfasst. Die Ankermuttern spielen in dieser Baugruppe eine entscheidende Rolle, da sie die Ankerstäbe sicher fixieren und sicherstellen, dass die Schalung unter dem immensen Druck des nassen Betons stabil bleibt.

Diese scheinbar kleinen Komponenten sind so konstruiert, dass sie schwere Lasten tragen können und verhindern, dass sich die Schalung während der Betonier- und Aushärtungsphase verschiebt oder verformt. Ohne zuverlässige Ankermuttern könnte das gesamte System versagen, was sowohl die Effizienz des Bauprozesses als auch die strukturelle Integrität des Endprodukts gefährden würde.

Das Zugstangensystem: Eine kohäsive Lösung

Das Ankerstabsystem fungiert als eine einheitliche Baugruppe zur Unterstützung und Stabilisierung von Betonschalungen.

- Zugstangen: Die zentrale Komponente des Systems, die Ankerstäbe, sind hochfeste Stahlstäbe, die den Druck des frisch gegossenen Betons aufnehmen und verteilen. Sie spannen sich über die Schalung und sorgen für die nötige Steifigkeit, um sie in Position zu halten.

- Wasserstopps: Die oft in die Zugstangen integrierten Fugenbleche fungieren als wichtige Barrieren, die verhindern, dass Wasser durch die Zugstangenlöcher eindringt. Diese Elemente erhöhen die Dauerhaftigkeit der Struktur, indem sie das Risiko von Wasserschäden mindern und die langfristige Leistungsfähigkeit sicherstellen.

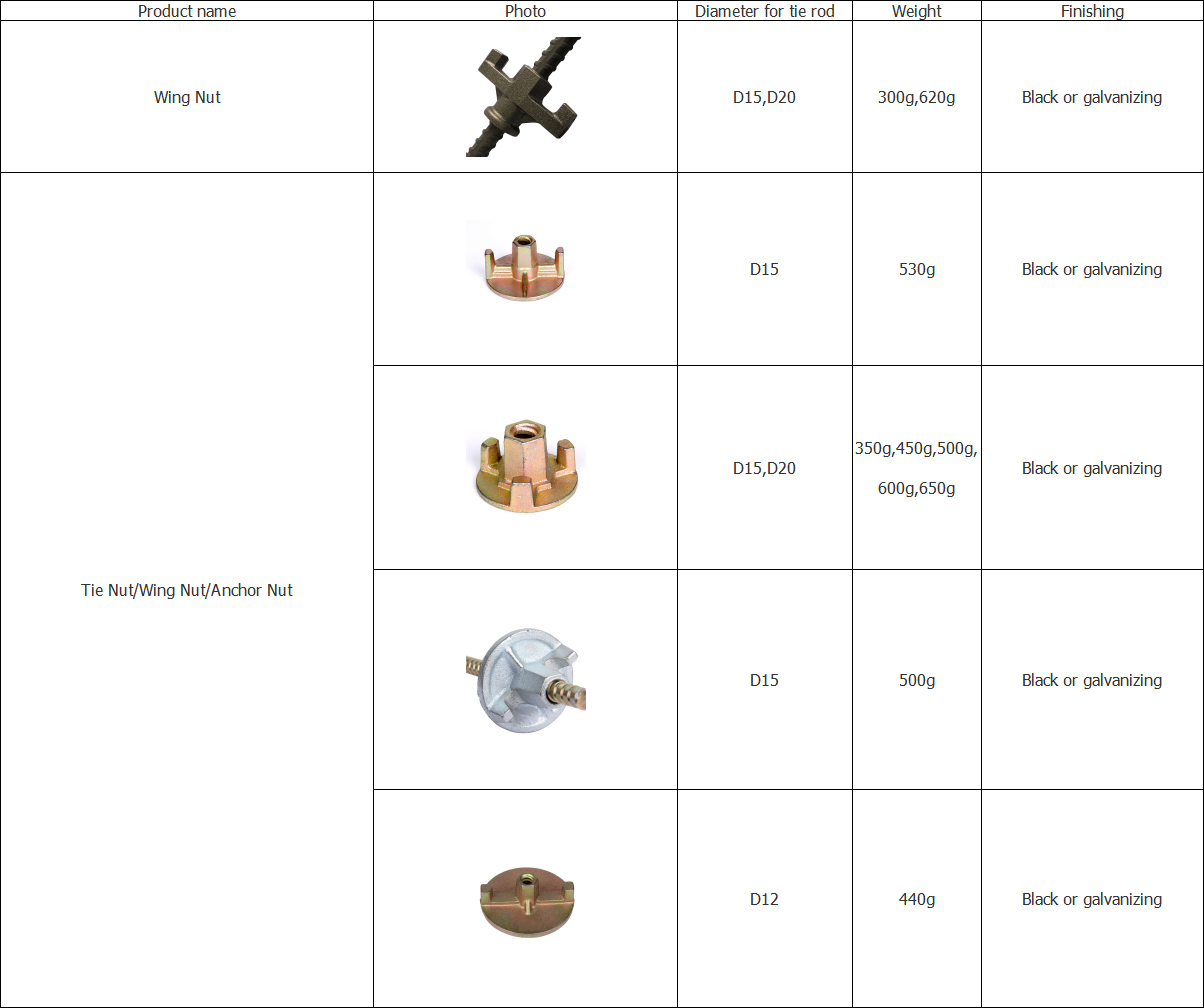

- Krawattenmuttern: An jedem Ende des Ankerstabs befinden sich Ankermuttern, mit denen die Stäbe fest an den Schalungselementen befestigt werden. Ihr Gewinde und ihre Festigkeit sind so ausgelegt, dass sie den hohen Beanspruchungen während der Bauarbeiten standhalten und die Ausrichtung und Stabilität der Schalung gewährleisten.

- Flügelmuttern: Die Flügelmuttern sind eine praktische Ergänzung des Systems und ermöglichen eine schnelle und werkzeuglose Einstellung. Sie sind besonders nützlich bei Anwendungen, die eine häufige Montage und Demontage erfordern und erhöhen die Effizienz, ohne die Sicherheit zu beeinträchtigen.

Zusammen bilden diese Komponenten einen robusten und zuverlässigen Rahmen, der den Erfolg von Betonbauprojekten von Anfang bis Ende gewährleistet.

Wie das Zugstangensystem die Effizienz der Konstruktion verbessert

Verbesserte Stabilität und Präzision

Das Ankerstabsystem beseitigt Bedenken hinsichtlich einer Fehlausrichtung oder Instabilität während der Schalungsphase. Durch die Fixierung der Schalungselemente mit Ankermuttern garantiert das System, dass die Struktur während des gesamten Betonier- und Aushärtungsprozesses ihre vorgesehene Form beibehält.

Darüber hinaus bietet die Integration von Wassersperren in die Baugruppe eine zusätzliche Schutzschicht. Diese Komponenten verhindern das Eindringen von Wasser in die Zugstangenlöcher, schützen die Integrität des Betons und verringern die Wahrscheinlichkeit zukünftiger Probleme wie Korrosion oder Risse.

Vereinfachte Montage und Demontage

Der Einsatz von Flügelmuttern im Ankerstabsystem rationalisiert den Montageprozess. Durch das Anziehen von Hand werden keine Spezialwerkzeuge benötigt, so dass die Bauarbeiter die Schalung schnell und effizient montieren und demontieren können. Das spart nicht nur Zeit, sondern senkt auch die Arbeitskosten und macht das System zu einer bevorzugten Wahl für Projekte aller Größenordnungen.

Vielseitigkeit bei verschiedenen Anwendungen

Dank seiner Anpassungsfähigkeit eignet sich das Ankerstabsystem für eine Vielzahl von Betonbauanwendungen, von einfachen Decken bis hin zu komplexen architektonischen Entwürfen. Seine Komponenten können an unterschiedliche Schalungsgrößen und -konfigurationen angepasst werden und bieten so die nötige Flexibilität, um verschiedene Projektanforderungen zu erfüllen.

Die wesentliche Rolle der Qualität bei Zugstangensystemen

Hochpräzise Fertigung für Zuverlässigkeit

Ankerstäbe, Ankermuttern, Fugenbänder und Flügelmuttern müssen hohen Qualitätsanforderungen genügen, um effektiv zu funktionieren. Jegliche Abweichungen bei den Abmessungen oder Gewinden können zu unsachgemäßen Passungen führen und die Stabilität des Schalungssystems beeinträchtigen. Die hochpräzise Fertigung stellt sicher, dass alle Komponenten nahtlos zusammenarbeiten und auf der Baustelle eine gleichbleibende Leistung erbringen.

Der Wert von Langlebigkeit und Stärke

In der Baubranche sind Schalungssysteme extremen Bedingungen ausgesetzt, von schweren Lasten bis hin zu Wasser und anderen Elementen. Langlebigkeit ist von größter Bedeutung, vor allem für Ankermuttern und Stangen, die während des Betoniervorgangs die Hauptlast des Drucks tragen. Durch die Auswahl von Komponenten aus hochwertigen Materialien wird sichergestellt, dass das System diesen Herausforderungen standhalten kann, ohne zu versagen.

Verbesserung der langfristigen strukturellen Integrität

Die Einbeziehung von Wasserstopps in das Zugstangensystem zeigt, wie wichtig proaktive Maßnahmen beim Bau sind. Indem sie das Eindringen von Wasser verhindern, tragen diese Komponenten zur langfristigen Haltbarkeit des Bauwerks bei, verringern den Wartungsbedarf und verlängern seine Lebensdauer.

Was uns auszeichnet

1. Engagierter, 24/7 Eins-zu-Eins-Kundendienst

Unser Team steht Ihnen rund um die Uhr zur Verfügung, um Sie persönlich zu betreuen und sich umgehend um Ihre Fragen und Anliegen zu kümmern, damit ein reibungsloser und zuverlässiger Ablauf gewährleistet ist.

2. Umfangreicher Lagerbestand, wettbewerbsfähige Preise und kostenlose Muster

Wir verfügen über einen soliden Lagerbestand, der eine schnelle und zuverlässige Abwicklung ermöglicht. Unsere wettbewerbsfähigen Preise und kostenlosen Muster ermöglichen es Ihnen, die Qualität aus erster Hand zu beurteilen und gewährleisten eine pünktliche und zuverlässige Lieferung innerhalb jedes Projektzyklus.

3. Strenge Qualitätskontrolle und ausführliche Inspektionsberichte

Unser strenges Qualitätsprüfungsverfahren gewährleistet, dass alle Produkte den höchsten Standards entsprechen. Jede Bestellung wird von detaillierten Prüfberichten begleitet, die für Sicherheit und konsistente Qualitätskontrolle sorgen.

4. Zertifizierte Exzellenz: CE und mehr für verlässliche Partnerschaften

Ähnliche Produkte

-

Zugstange PVC-Rohr

$1.00 -

Superplatte Kombi-Mutter

$1.00 -

Schalung Water Stop

$1.00