Concrete Turnbuckle

Concrete turnbuckles have been a mainstay in the construction industry for quite some time and ensure accuracy in tensioning and alignment during formwork. Most buyers of such turnbuckles consider the aspects of durability, ease of operation, and optimum performance. From H&F, we cater to diverse projects by offering different products: bent plate and flat plate varieties, with assured one-to-one customer service that allows tailoring in terms of products, fast delivery cycles, and complete quality inspection reports, which give assurance at the end.

Understanding Concrete Turnbuckles

When it comes to construction projects, concrete turnbuckles play a crucial role in maintaining stability and precision. These essential components allow contractors to adjust tension in formwork, making it possible to achieve precise alignment during concrete pours. At H&F, we know just how important these seemingly simple devices are – they can make or break a project’s success.

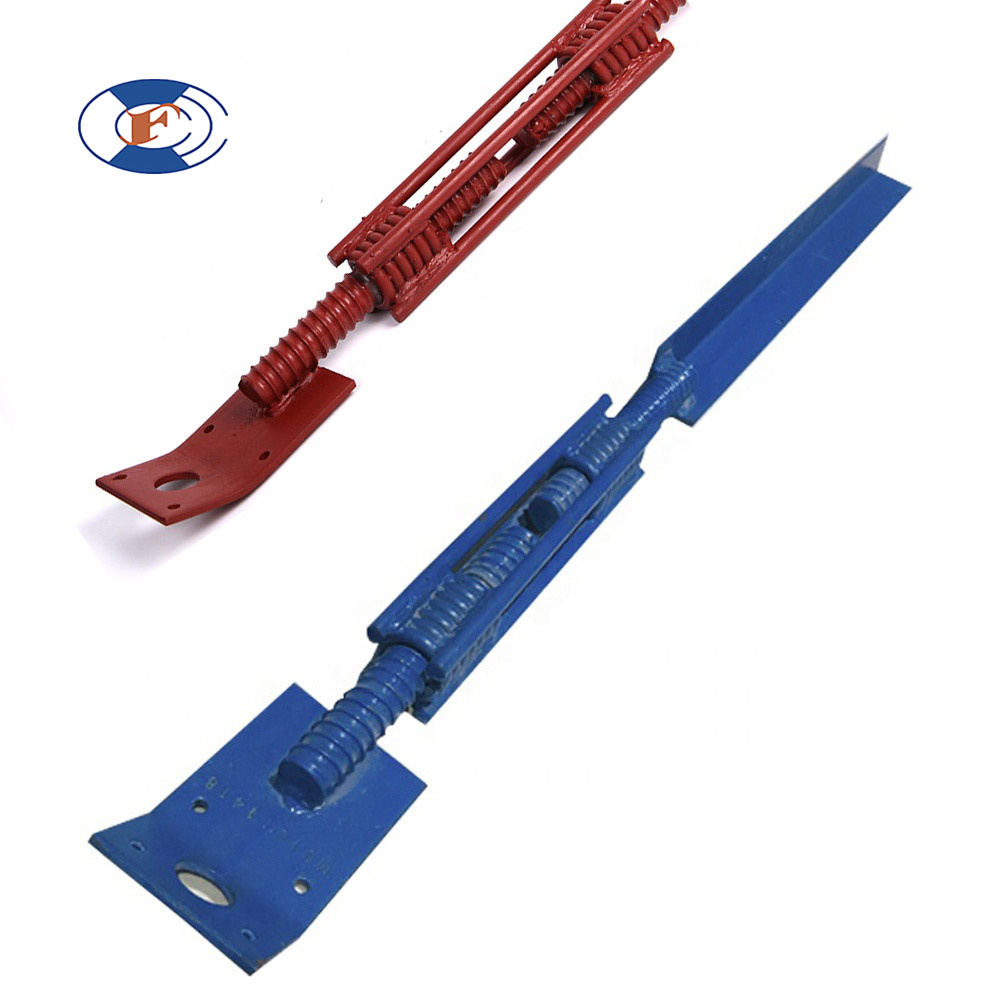

The construction industry primarily uses two varieties of concrete turnbuckles: bent plate and flat plate designs. Each has its own set of advantages, making them suitable for different types of projects and applications.

Bent Plate Turnbuckles

Bent plate turnbuckles feature a distinctive curved design that gives them an edge in certain applications. Their shape isn’t just for show – it helps spread force more evenly, making them especially valuable when dealing with shifting loads or unusual stress patterns. Construction teams often prefer these models when they need to make frequent adjustments since they’re typically easier to handle and adjust on the fly.

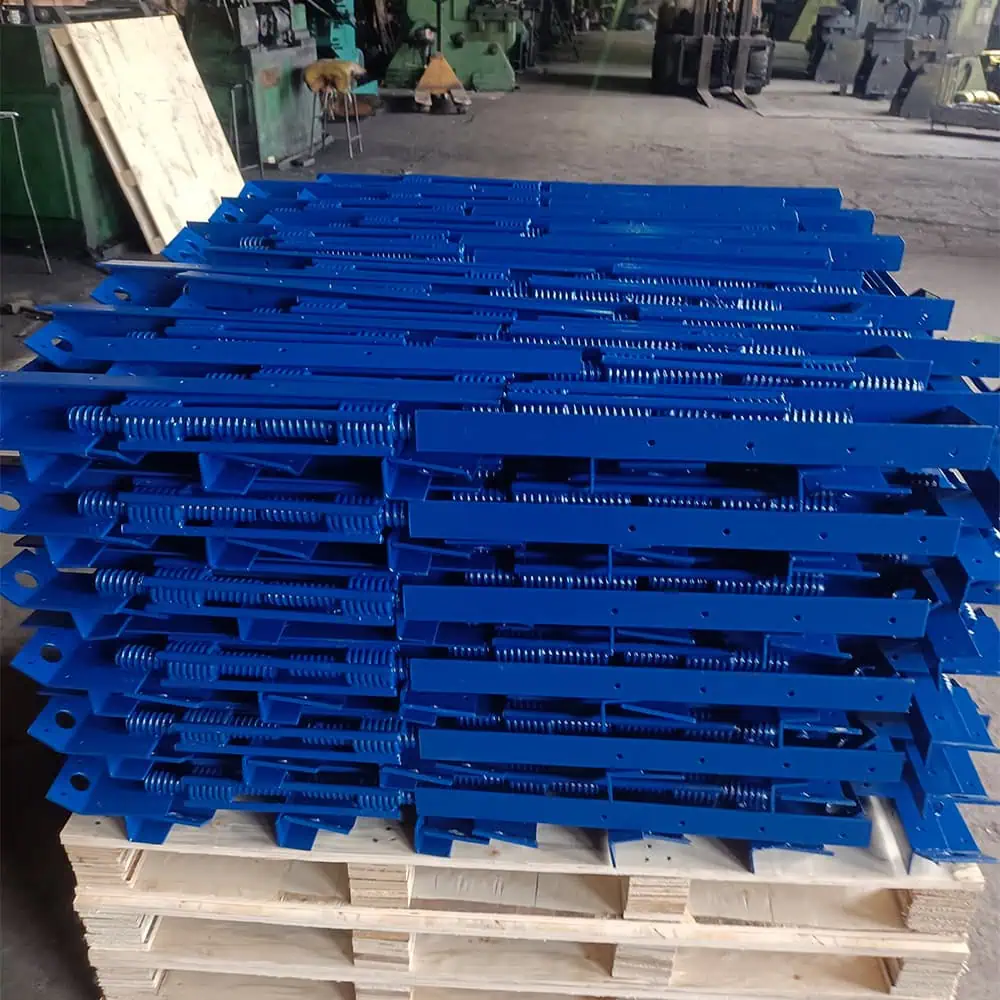

We at H&F manufacture our bent plate turnbuckles using top-tier materials, putting each unit through rigorous testing. Every turnbuckle comes with detailed quality reports, so you know exactly what you’re getting.

Flat Plate Turnbuckles

If you’re looking for something more straightforward, flat plate turnbuckles might be your best bet. Their no-nonsense design makes them a breeze to install, and they integrate smoothly with most formwork systems. Many contractors choose these models when they need reliable performance without breaking the bank.

Our flat plate turnbuckles are manufactured with the same attention to detail as their bent plate cousins. We work directly with our clients to understand their specific requirements, ensuring they get exactly what their project needs.

Why Choose H&F for Your Concrete Turnbuckles?

Picking the right supplier matters just as much as choosing the right product. At H&F, we go beyond just selling turnbuckles – we build partnerships. Our personalized approach means you’ll work with a dedicated representative who understands your project’s unique challenges and requirements.

We know construction timelines are tight, which is why we’ve streamlined our delivery process to get you what you need when you need it. Delays cost money, and we’re committed to keeping your project on track.

Quality isn’t just a buzzword for us – it’s built into everything we do. Every turnbuckle goes through comprehensive testing before it leaves our facility. We provide detailed inspection documentation so you can verify that each product meets or exceeds industry standards.

Whether you need bent plate or flat plate turnbuckles, we offer various sizes and configurations to match your specific application. Our team is always ready to help you select the right option or develop a custom solution for your unique challenges. We understand that no two construction projects are exactly alike, and we’re here to provide turnbuckles that work for your specific situation.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

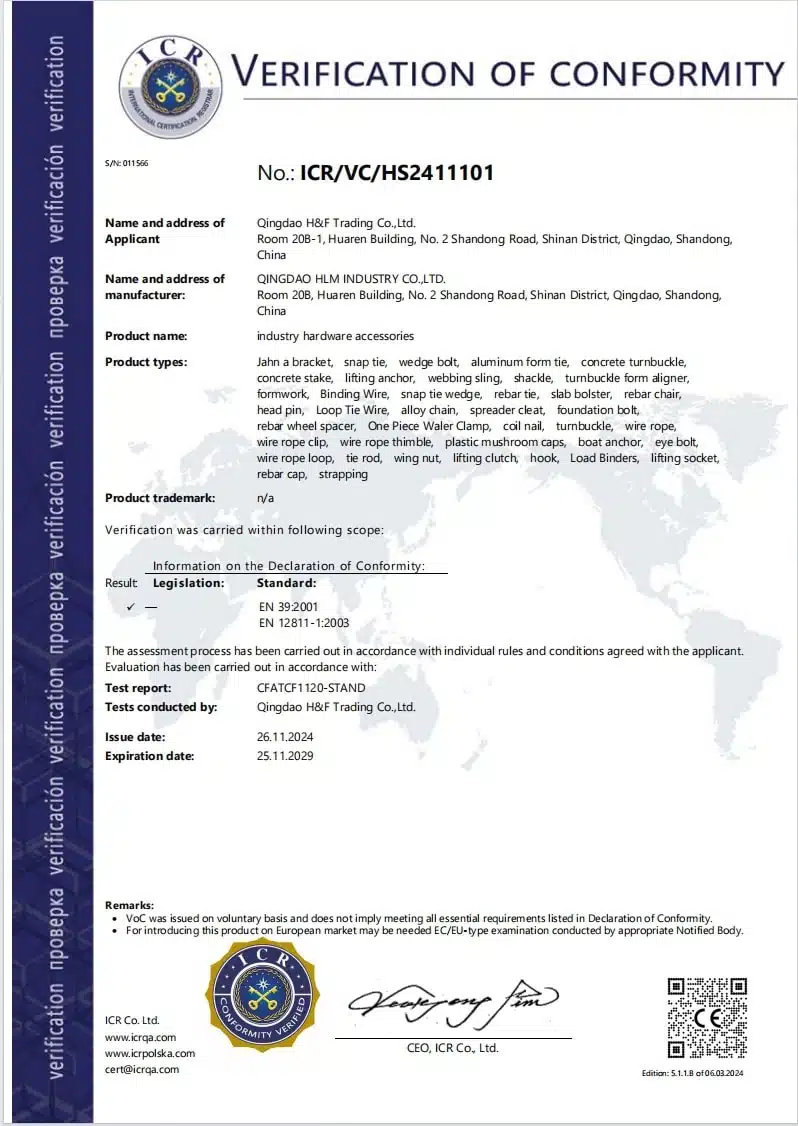

4. Certified Excellence: CE and More for Reliable Partnerships

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Related products

-

Snap Tie Wedge

$0.01