Wire rope thimble is a crucial component used in securing and protecting wire ropes from wear and tear. Acting as a guide for the rope, it prevents it from becoming frayed or damaged due to constant movement and tension. In essence, a wire rope thimble ensures the longevity and safety of wire rope applications by providing a reinforced loop through which the rope can pass.

The Type of Wire Rope Thimble

Wire rope thimbles come in various types, each designed to suit specific applications and environments. These types include:

Standard Thimbles:

These are the most common type of thimbles, featuring a simple design with rounded edges to prevent chafing of the wire rope.

Heavy-Duty Thimbles:

As the name suggests, heavy-duty thimbles are built to withstand greater loads and harsher conditions. They are often made of thicker materials for enhanced durability.

Stainless Steel Thimbles:

Ideal for applications where corrosion resistance is essential, stainless steel thimbles offer excellent protection against rust and degradation, making them suitable for marine and outdoor environments.

Galvanized Thimbles:

Galvanized thimbles are coated with a layer of zinc to provide corrosion protection, making them suitable for outdoor use and industrial applications.

Plastic-Coated Thimbles:

These thimbles feature a plastic coating that provides additional protection to the wire rope and prevents it from scratching or damaging surfaces it comes into contact with.

Round Thimble:

The round thimble is perhaps the most widely recognized type. Its simple yet effective design features rounded edges to prevent chafing of the wire rope. Round thimbles are versatile and suitable for a wide range of applications, from general-purpose rigging to marine and industrial uses.

Wire Rope Tube Thimble:

Wire rope tube thimbles offer enhanced strength and durability compared to their round counterparts. Their elongated shape provides a larger bearing surface, distributing the load more evenly and reducing the risk of deformation or damage to the wire rope. Wire rope tube thimbles are often preferred for heavy-duty applications or where extra reinforcement is needed to withstand high loads and harsh conditions.

How to Install Thimble on Wire Rope

Installing a thimble on a wire rope is a straightforward process that ensures the rope’s integrity and longevity. Follow these steps for proper installation:

Select the Right Thimble: Choose a thimble that matches the diameter and material of your wire rope, ensuring a proper fit and optimal performance.

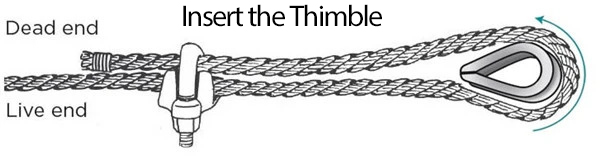

Insert the Thimble: Slide the thimble into the loop of the wire rope, ensuring that it sits securely and centrally within the loop.

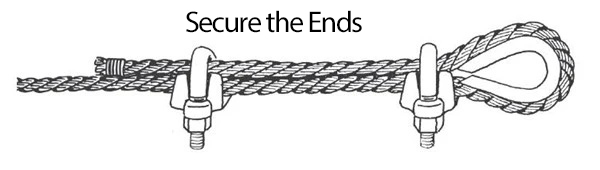

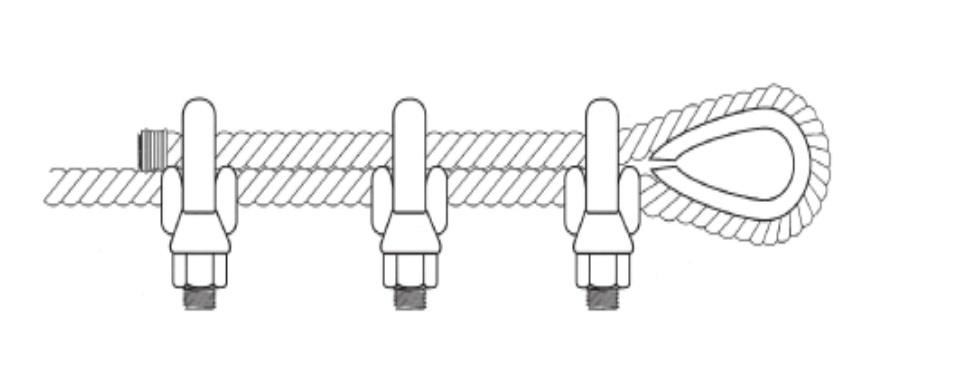

Secure the Ends: Use wire rope clips or swage sleeves to secure the ends of the wire rope together, ensuring a tight and secure connection.

Test the Installation: Before putting the wire rope into service, perform a visual inspection to ensure that the thimble is properly seated and the connections are secure. Test the assembly under a light load to confirm its integrity.

Regular Maintenance: Periodically inspect the wire rope and thimble assembly for signs of wear or damage, and replace any components that show signs of fatigue to maintain safety and performance.

Conclusion about Install Thimble

Proper installation of a thimble on a wire rope is essential for ensuring the safety and longevity of the rope. By following the steps outlined above and selecting the appropriate type of thimble for your application, you can effectively protect your wire rope from wear and damage, thereby maximizing its lifespan and performance.

FAQs about Install Thimble on Wire Rope

Can I reuse wire rope thimbles?

Yes, wire rope thimbles can typically be reused if they are in good condition and have not been subjected to excessive wear or damage. However, it’s essential to inspect thimbles regularly for signs of wear, corrosion, or deformation and replace them if necessary to ensure the safety and integrity of the wire rope assembly.

What is the purpose of using a thimble in wire rope applications?

A thimble serves several purposes in wire rope applications, including providing a reinforced loop through which the rope can pass, preventing the rope from becoming frayed or damaged, and distributing the load evenly across the rope’s diameter. Additionally, thimbles help to maintain the integrity of the rope under tension and protect it from wear and abrasion.

How do I determine the correct size of thimble for my wire rope?

To determine the correct size of thimble for your wire rope, measure the diameter of the rope and select a thimble that matches this size. Thimbles are available in various diameters to accommodate different sizes of wire rope, so be sure to choose one that fits snugly without being too tight or too loose.

Can I install a thimble on a wire rope without using wire rope clips or swage sleeves?

While wire rope clips or swage sleeves are typically used to secure the ends of a wire rope together after installing a thimble, alternative methods such as knotting or welding may also be used in some applications. However, it’s essential to ensure that any alternative method used is capable of providing a secure and reliable connection that meets the requirements of the specific application.

How do I know if my wire rope thimble needs to be replaced?

Inspect your wire rope thimble regularly for signs of wear, corrosion, or deformation, such as cracks, dents, or elongation of the eye. If you notice any such signs or if the thimble does not fit securely within the wire rope loop, it should be replaced immediately to prevent compromising the integrity and safety of the wire rope assembly.

Are there any special considerations for installing thimbles in marine environments?

In marine environments, where exposure to saltwater and corrosion is a concern, it’s essential to use thimbles made from corrosion-resistant materials such as stainless steel or galvanized steel. Additionally, regular maintenance and inspection of wire rope assemblies are crucial to identify and address any signs of corrosion or wear before they compromise the integrity of the assembly.

Can I install a thimble on a wire rope without specialized tools?

While specialized tools such as wire rope clamps or swaging tools may make the installation process easier and more efficient, it is possible to install a thimble on a wire rope using basic hand tools such as pliers or wrenches. However, it’s essential to ensure that the installation is done correctly and securely to prevent any issues with the wire rope assembly.

How do I prevent galvanic corrosion when using wire rope thimbles?

Galvanic corrosion can occur when dissimilar metals are in contact with each other in the presence of an electrolyte, such as saltwater. To prevent galvanic corrosion when using wire rope thimbles, it’s essential to choose thimbles made from materials that are compatible with the wire rope and any other metal components in the assembly. Additionally, using insulating materials or coatings can help to isolate the metals and minimize the risk of corrosion.

Are there any regulatory standards or guidelines for installing wire rope thimbles?

While there are no specific regulatory standards for installing wire rope thimbles, it’s essential to follow the manufacturer’s recommendations and industry best practices to ensure the safety and integrity of the wire rope assembly. Additionally, consulting relevant industry standards and guidelines, such as those published by organizations like the American Society for Testing and Materials (ASTM) or the Occupational Safety and Health Administration (OSHA), can provide valuable guidance on proper installation techniques and safety requirements.

Can I install a thimble on a wire rope that has already been in service?

Yes, it is possible to install a thimble on a wire rope that has already been in service, provided that the rope and thimble are in good condition and have not been subjected to excessive wear or damage. However, it’s essential to inspect the wire rope and thimble thoroughly before installation to ensure that they are suitable for continued use and that any worn or damaged components are replaced as needed.