This article provides a comprehensive guide on how to measure different types of shackles accurately. It covers the measurement techniques for bow shackles (anchor shackles) and D shackles (chain shackles), along with important notes on measurement to avoid common mistakes. The article concludes with a summary of key points and addresses frequently asked questions regarding shackle measurement.

TYPES OF SHACKLES

Bow Shackle (Anchor Shackle)

Bow shackles, also known as anchor shackles, are commonly used in rigging applications. Proper measurement ensures the correct fit and safe operation of these shackles.

Measurement Technique:

Measure the diameter of the bow, excluding the pin.

Measure the width of the bow at its widest point.

Measure the distance between the eyes of the shackle, known as the inside length.

D Shackle (Chain Shackle)

D shackles, or chain shackles, are widely used in lifting and rigging operations. Precise measurement is crucial for selecting the appropriate shackle for the intended application.

Measurement Technique:

Measure the diameter of the straight portion of the shackle, excluding the pin.

Measure the width of the straight portion at its widest point.

Measure the distance between the eyes of the shackle, known as the inside length.

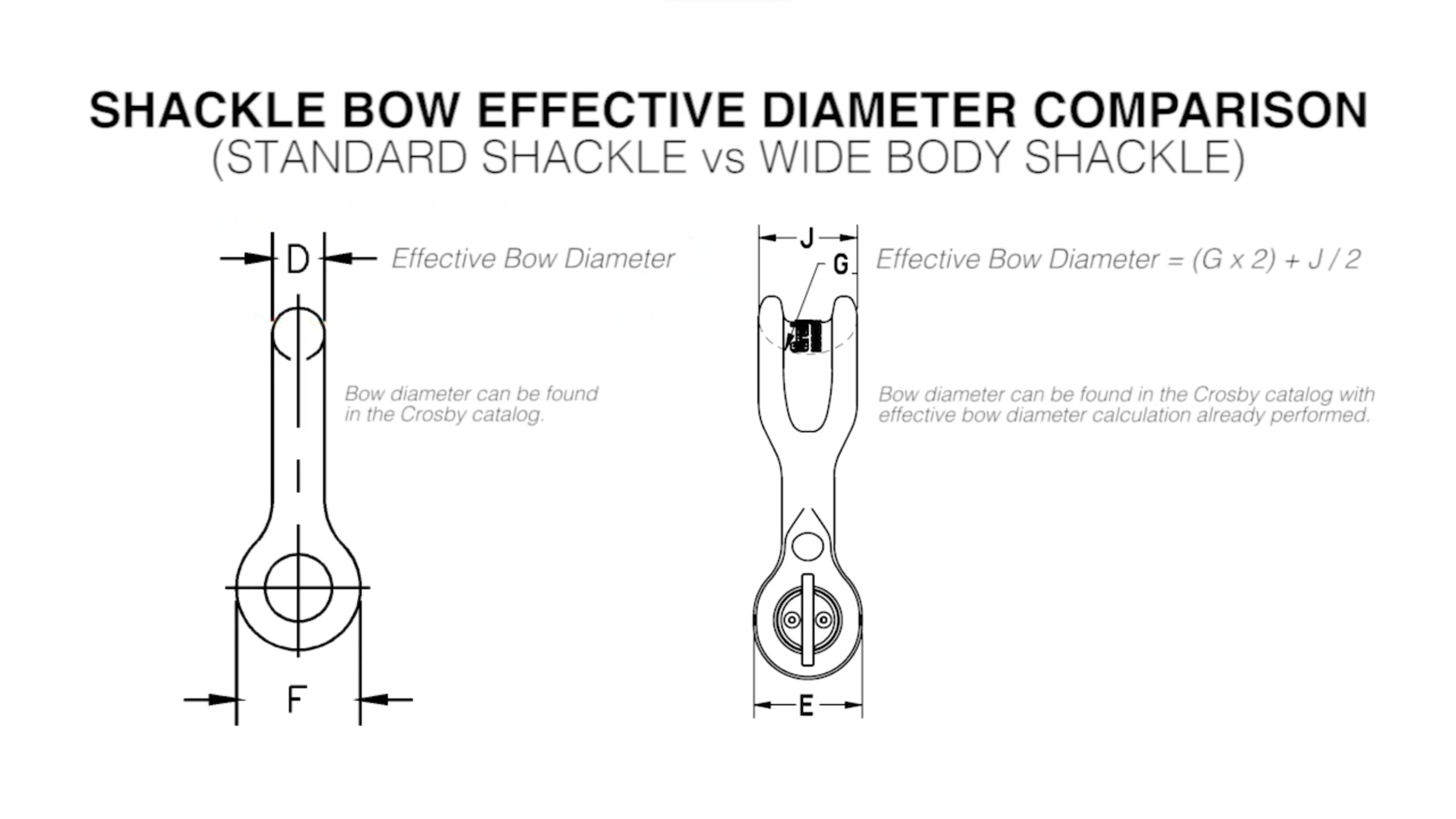

Effective Diameter Comparison: Standard vs. Wide Body Shackles

Understanding the effective diameter difference between standard and wide body shackles is essential for choosing the right one for your application. Here’s a breakdown:

Effective Diameter:

Standard Shackle:

Refers to the inner diameter of the bow or the clear width of the D opening. This determines the maximum size of chain, rope, or other components that can safely pass through.

Wide Body Shackle:

While it also has an inner diameter/width, its effective diameter is larger due to its wider body design. This allows for greater bearing surface area and load distribution, offering benefits like:

Increased working load limit (WLL): Can handle heavier loads compared to standard shackles of the same size.

Reduced stress on components: Distributes load more evenly, minimizing wear and tear on the shackle and connected elements.

Improved stability: Wider body provides better resistance to bending and deformation under load.

Notes on Measurement

Accurate measurement of shackles is essential to ensure safety and proper functionality. Here are some important considerations to avoid measurement errors:

Use calipers or a measuring tape for precise measurements.

Measure in millimeters for accuracy, especially for smaller shackles.

Take multiple measurements to confirm accuracy, especially when ordering custom shackles.

Consult manufacturer specifications for specific measurement guidelines.

Conclusion about Measuring a Shackle

Proper measurement of shackles is vital for safe and efficient rigging operations. By following the techniques outlined in this article and adhering to recommended guidelines, users can ensure the correct selection and usage of shackles for their applications.

FAQs about Measuring a Shackle

1. How do I measure the size of a shackle?

To measure the size of a shackle, determine its diameter, width, and inside length using a measuring tape or calipers.

2. Can I measure a shackle without specialized tools?

While specialized tools like calipers provide more accurate measurements, a measuring tape can also be used effectively for basic measurements.

3. What is the importance of measuring a shackle accurately?

Accurate measurement ensures proper fit, functionality, and safety of shackles in various applications, reducing the risk of accidents or failures.

4. Are there standard sizes for shackles?

Yes, shackles come in standard sizes, but custom sizes can also be ordered based on specific requirements.

5. Can I measure a shackle while it’s in use?

It’s not recommended to measure a shackle while it’s in use due to safety concerns. Remove the shackle from the application before taking measurements.

6. How do I measure the diameter of a shackle pin?

Use calipers or a micrometer to measure the diameter of the shackle pin accurately.

7. Should I measure the shackle with or without the pin?

Measure the shackle without the pin to obtain accurate dimensions for selection and compatibility.

8. Are there any specific guidelines for measuring stainless steel shackles?

While the measurement techniques remain the same, consider factors like corrosion resistance and material strength when selecting stainless steel shackles.

9. Can I use a ruler instead of a measuring tape?

A ruler can be used if it provides accurate measurements in millimeters, ensuring precision in shackle measurement.

10. What should I do if my measurements fall between standard sizes?

– In cases where measurements fall between standard sizes, consider consulting with a manufacturer for custom sizing options to meet specific requirements.

11. What is the best shacke supplier?

H&F is a supplier specializing in rigging hardware. it has the best products and services.