Webbing slings are indispensable tools in material handling and lifting operations across various industries. These slings are designed to provide safe and efficient methods for securing, lifting, and moving heavy loads. This article aims to offer a comprehensive guide on how to use webbing slings, introducing you to the specific usage of various types available in the market.

Understanding the Versatility of Webbing Slings

Webbing slings are typically constructed from high-strength materials such as polyester or nylon webbing. They are flexible, lightweight, and durable, making them a preferred choice for a wide range of applications.

Flat Webbing Slings:

Flat webbing slings, as the name suggests, have a flat, rectangular shape. They are known for their versatility and are widely used in different lifting and securing tasks. These slings offer excellent load distribution and are ideal for use on delicate or irregularly shaped loads.

Round Webbing Slings:

Round webbing slings are designed in a continuous loop, forming a cylindrical shape. These slings are well-suited for use in choker hitches and are particularly effective when dealing with loads that have sharp edges. They distribute the load evenly and provide flexibility when handling loads of various shapes and sizes.

Endless Webbing Slings:

Endless webbing slings are endless loops with no seams or eyelets. They are incredibly adaptable and can be used in a variety of hitches, making them a versatile choice for lifting and securing loads.

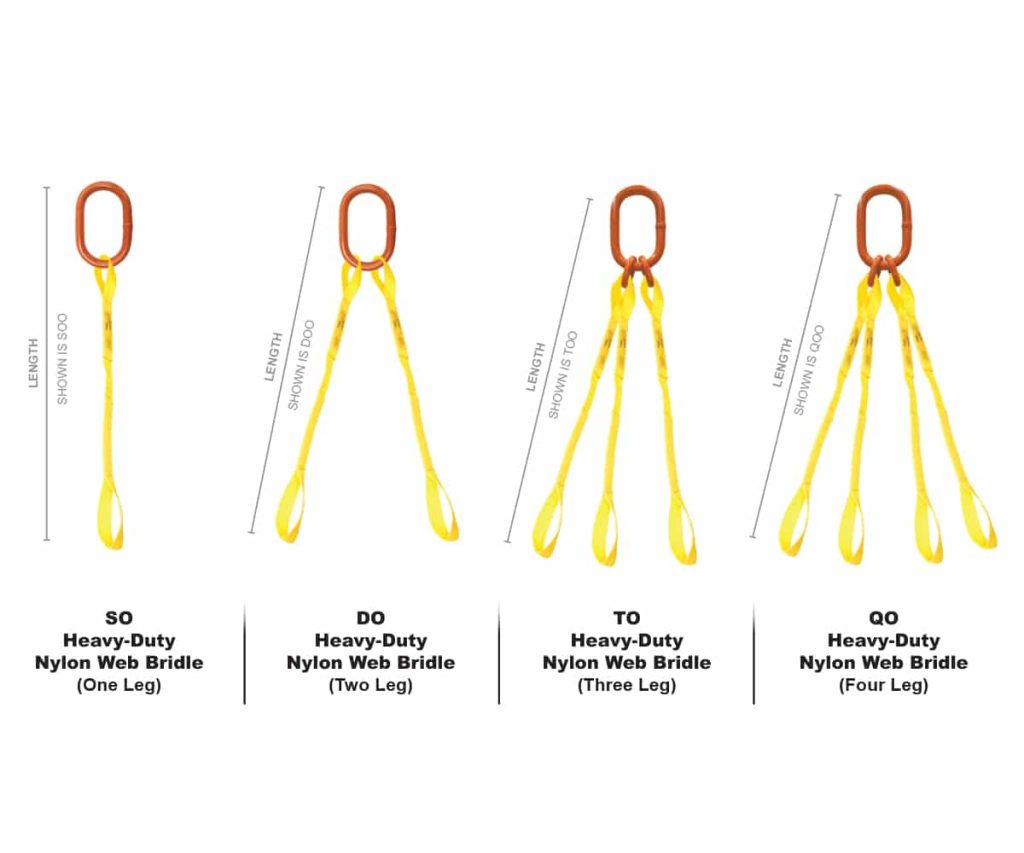

Multi-Leg Webbing Slings:

Multi-leg webbing slings consist of multiple individual legs attached to a common master link or hook. They are designed to lift heavy and complex loads, providing stability and control while distributing the weight evenly among the legs.

Using Flat Webbing Slings

Flat webbing slings are employed in several ways:

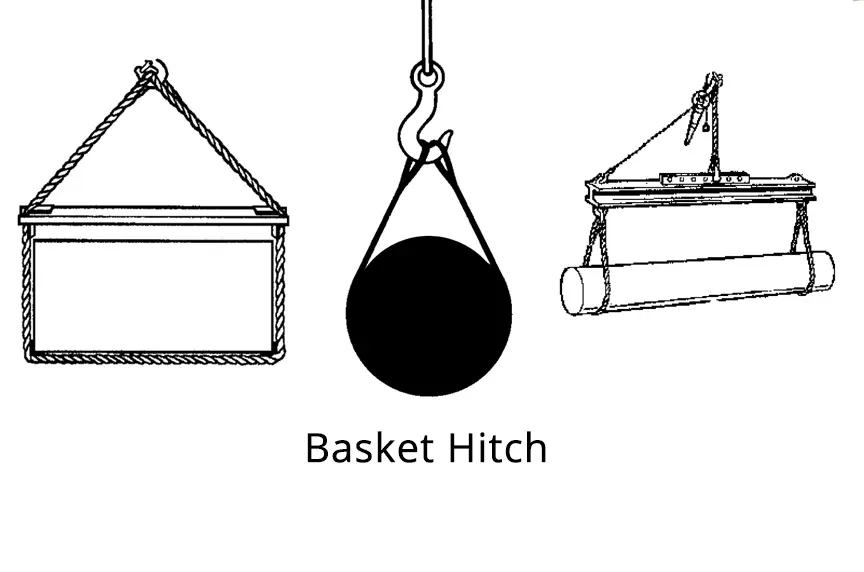

Basket Hitch

In a basket hitch configuration, the sling is placed under the load and then brought up to attach to the lifting equipment. This method is suitable for loads with flat and stable surfaces.

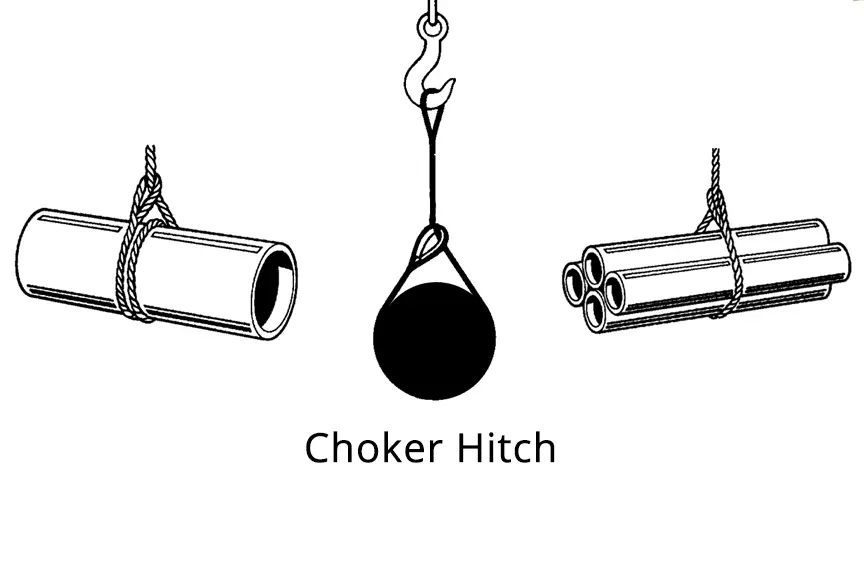

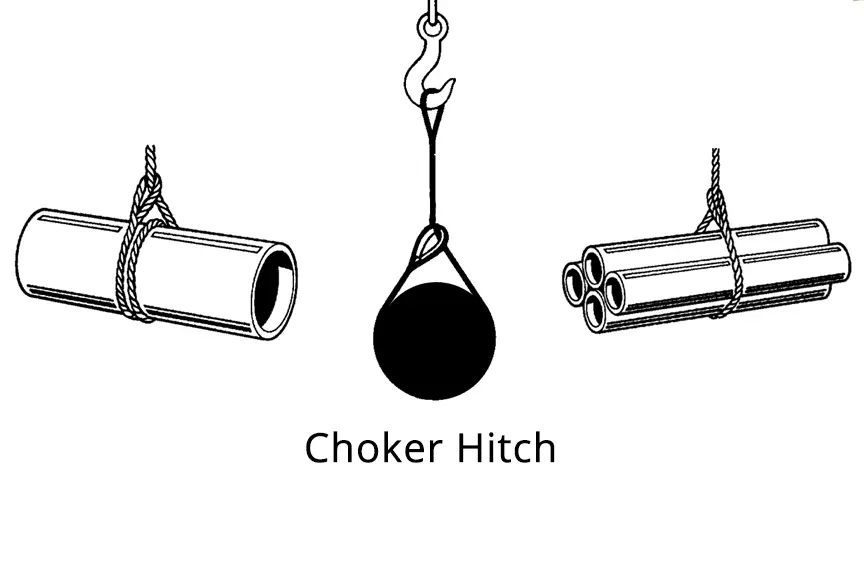

Choker Hitch

To create a choker hitch, the sling is looped around the load and then passed through one of its eyes, forming a “choke” around the load. This method is ideal for cylindrical loads or those with irregular shapes.

Vertical Hitch

In a vertical hitch, the sling is attached to the lifting equipment, and the load is lifted directly upwards. This is the simplest and most common way to use a flat webbing sling.

Using Round Webbing Slings

Round webbing slings are equally versatile and can be used in the following configurations:

Basket Hitch

Similar to flat slings, round slings can be used in a basket hitch. The load is placed within the loop of the round sling, and it is then attached to the lifting equipment.

Choker Hitch

Round slings excel in choker hitches, where the sling is looped around the load and then passed through one of its eyes. The round shape of the sling ensures even distribution of the load.

Vertical Hitch

Using a round sling in a vertical hitch is straightforward. Attach the sling to the lifting equipment and lift the load directly upwards.

Using Endless Webbing Slings

Endless webbing slings are flexible and can be used in a variety of hitches, including basket, choker, and vertical configurations. They offer the advantage of not having any seams or eyelets, allowing you to adjust the length as needed for your specific load.

Using Multi-Leg Webbing Slings

Multi-leg webbing slings are employed for complex loads and typically involve attaching each leg to a different part of the load. This configuration ensures balanced lifting and control over the load, making it suitable for irregularly shaped or heavy items.

General Safety Tips for Using Webbing Slings

Prior to each use, inspect the webbing sling for signs of wear, damage, or deterioration.

Ensure the weight of the load does not exceed the sling’s rated capacity, as specified by the manufacturer.

Protect the sling from sharp edges, abrasive surfaces, or chemicals that may cause damage or degradation.

Use appropriate lifting equipment and attachment points that are compatible with the webbing sling’s configuration.

Conclusion about Use Webbing Slings

Webbing slings, available in various types such as flat, round, endless, and multi-leg, are essential tools for material handling in a multitude of industries. Understanding how to use these slings safely and efficiently is paramount to the success of your lifting and securing operations. By following the guidelines provided in this article, you can ensure the safe and effective use of webbing slings for a wide range of applications.

FAQS about Use Webbing Slings

How do I calculate the working load limit (WLL) for a webbing sling in my specific application?

Answer: To determine the WLL, you should consider the type of webbing sling, its configuration, and the angle of the load. Manufacturers provide charts and guidelines to help you calculate the appropriate WLL for your situation.

Can webbing slings be used for lifting sharp or abrasive loads?

Answer: Yes, webbing slings are suitable for lifting sharp or abrasive loads. However, it’s important to use protective accessories, such as wear pads, to prevent damage to the sling.

Are there any regulations or standards I should be aware of when using webbing slings?

Answer: Yes, several safety standards, such as ASME B30.9 and OSHA regulations, govern the use of webbing slings. It’s essential to be familiar with these standards and ensure compliance in your lifting operations.

Can webbing slings be repaired if they are damaged or show signs of wear and tear?

Answer: Webbing slings should not be repaired if they are damaged. Damaged slings should be removed from service and replaced with new ones to maintain safety.

How do I properly store webbing slings when they are not in use?

Answer: Store webbing slings in a cool, dry place, away from direct sunlight and sources of heat. Keep them off the ground and protect them from contaminants, such as chemicals or sharp objects.

Can webbing slings be used for overhead lifting applications?

Answer: Yes, webbing slings are suitable for overhead lifting. However, ensure that the lifting equipment and rigging are properly rated for overhead applications, and follow all safety precautions.

What should I do if a webbing sling gets wet or comes into contact with chemicals during use?

Answer: If a webbing sling gets wet or comes into contact with chemicals, it should be removed from service and inspected for damage. Soaking in chemicals or prolonged exposure to moisture can weaken the sling.

Is it necessary to label or tag webbing slings for easy identification and tracking?

Answer: Yes, labeling and tagging webbing slings is crucial for easy identification and tracking. This helps in verifying the sling’s specifications, inspecting it, and ensuring it is used correctly.

Can webbing slings be used in extreme temperature conditions, such as very high or low temperatures?

Answer: Webbing slings have temperature limits, and it’s essential to follow the manufacturer’s recommendations. Extremely high or low temperatures can affect the strength and durability of the sling.

How often should I inspect webbing slings for wear and damage?

Answer: Regular inspections are vital for safety. You should inspect webbing slings before each use, during use if they are subjected to harsh conditions, and annually or as specified by safety regulations.