Bolt Type Shackle

Bolt Type Shackles, such as the popular G2130 and G2140 models, are essential rigging components designed for lifting, towing, and securing heavy loads. With capacities ranging widely, these shackles support working load limits (WLL) from 0.33 tons to 150 tons, with sizes typically spanning from 1/4 inch to 3 inches. Buyers often prioritize strength, durability, and safety assurances, making quality inspection reports a key factor in purchasing decisions. At Qingdao H&F, we enhance this experience by offering a fast delivery cycle, one-on-one customer support, and comprehensive quality verification through inspection reports. These services underscore our commitment to ensuring buyers receive reliable, high-performance shackles tailored to their requirements.

Understanding the Role and Specifications of Bolt Type Shackles

Bolt Type Shackles, often recognized by models like the G2130 and G2140, are foundational tools in rigging, towing, and lifting applications. Their robust design is intended to secure connections and support substantial loads safely. The bolt-type design, particularly, offers additional security compared to other shackle types, making them highly suitable for long-term or semi-permanent installations where enhanced stability is essential.

What sets Bolt Type Shackles apart is their capacity to handle high working loads safely, with models like G2130 and G2140 offering a broad spectrum of sizes and WLL options. This versatility enables users across industries—be it construction, marine, or manufacturing—to select the precise shackle that aligns with their project specifications. When selecting a shackle, WLL and size are among the foremost considerations, as they directly impact the shackle’s ability to perform under varying weight loads. The WLL for these bolt type shackles generally ranges from 0.33 tons to 150 tons, while size ranges from 1/4 inch to 3 inches, providing options to suit different rigging requirements and environmental conditions.

Beyond their size and strength, another notable advantage of the G2130 and G2140 bolt-type shackles is their design, which allows for easy, secure pin fastening. This aspect is crucial, as the bolt-and-nut configuration prevents accidental release, thus safeguarding both the load and the rigging crew. Made from high-quality, high-tensile steel and often galvanized for corrosion resistance, these shackles deliver lasting durability in both indoor and outdoor applications.

Benefits of Choosing High-Quality Bolt Type Shackles from a Reliable Supplier

When purchasing bolt-type shackles, quality assurance is essential. Qingdao H&F stands out by prioritizing strict quality standards, as we understand that buyers need the peace of mind that their products meet safety requirements. Our shackles undergo multiple quality inspections before shipping, with detailed inspection reports provided. These reports ensure that each product aligns with the required strength and resilience standards, helping buyers make informed choices based on verified data.

In addition to rigorous quality testing, we provide one-on-one customer service to assist buyers in finding the most suitable shackle for their specific needs. With our fast delivery cycle, Qingdao H&F reduces wait times, ensuring that buyers receive their products promptly, even when dealing with tight project schedules. This combination of fast, reliable service and an emphasis on quality makes us a preferred partner for bulk purchases of high-performing G2130 and G2140 bolt type shackles.

Our commitment to customer satisfaction is grounded in providing transparency, reliability, and expert guidance to ensure a smooth procurement process. Each interaction is designed to offer clients valuable insights on product compatibility, installation procedures, and maintenance practices. This one-on-one service is particularly beneficial for clients seeking tailored solutions, as our team can offer advice based on project-specific requirements.

Key Considerations in Selecting and Using Bolt Type Shackles

Selecting the correct bolt-type shackle depends on various factors, with the WLL and shackle size being crucial to safe usage. The WLL dictates the maximum load the shackle can handle, while size influences fit and compatibility within the rigging setup. Inadequate sizing or load capacity can compromise safety, leading to potential equipment failure. Thus, matching the correct WLL and size to the intended application is paramount for safe and efficient performance.

Understanding the distinct advantages of different materials and finishes can further guide selection. For instance, galvanized steel bolt type shackles offer enhanced corrosion resistance, making them ideal for harsh or maritime environments. Additionally, the bolt-and-nut design, as seen in G2130 and G2140 models, provides a level of stability and security not found in other shackle types. This configuration minimizes the likelihood of pin slippage, making these shackles suitable for applications where loads may shift or vibrate, such as in transport or heavy industrial lifting.

Maintenance is another factor that influences the longevity and performance of bolt type shackles. Regular inspection is essential to ensure shackles are free from corrosion, deformation, or fatigue. For clients who purchase from Qingdao H&F, we offer usage guidelines and maintenance tips tailored to different industry needs, helping prolong product lifespan and maximize value. Our team can assist buyers with maintenance practices that ensure the safe and reliable operation of each shackle, reinforcing our commitment to client satisfaction and operational safety.

In summary, Bolt Type Shackles like the G2130 and G2140 play an indispensable role in various industrial applications. Their unique design and versatility allow them to accommodate high-load demands while providing security through the bolt-and-nut fastening mechanism. For buyers, choosing a trusted supplier is key to obtaining products that meet stringent quality standards. Qingdao H&F offers a combination of fast delivery, extensive quality checks, and one-on-one service, ensuring that each purchase enhances productivity, safety, and ease of use for every client.

Through our continuous commitment to quality and customer service, we aim to become the trusted partner for buyers seeking high-performance bolt type shackles that are built to withstand demanding environments.

G2130 shackle

G2130A shackle

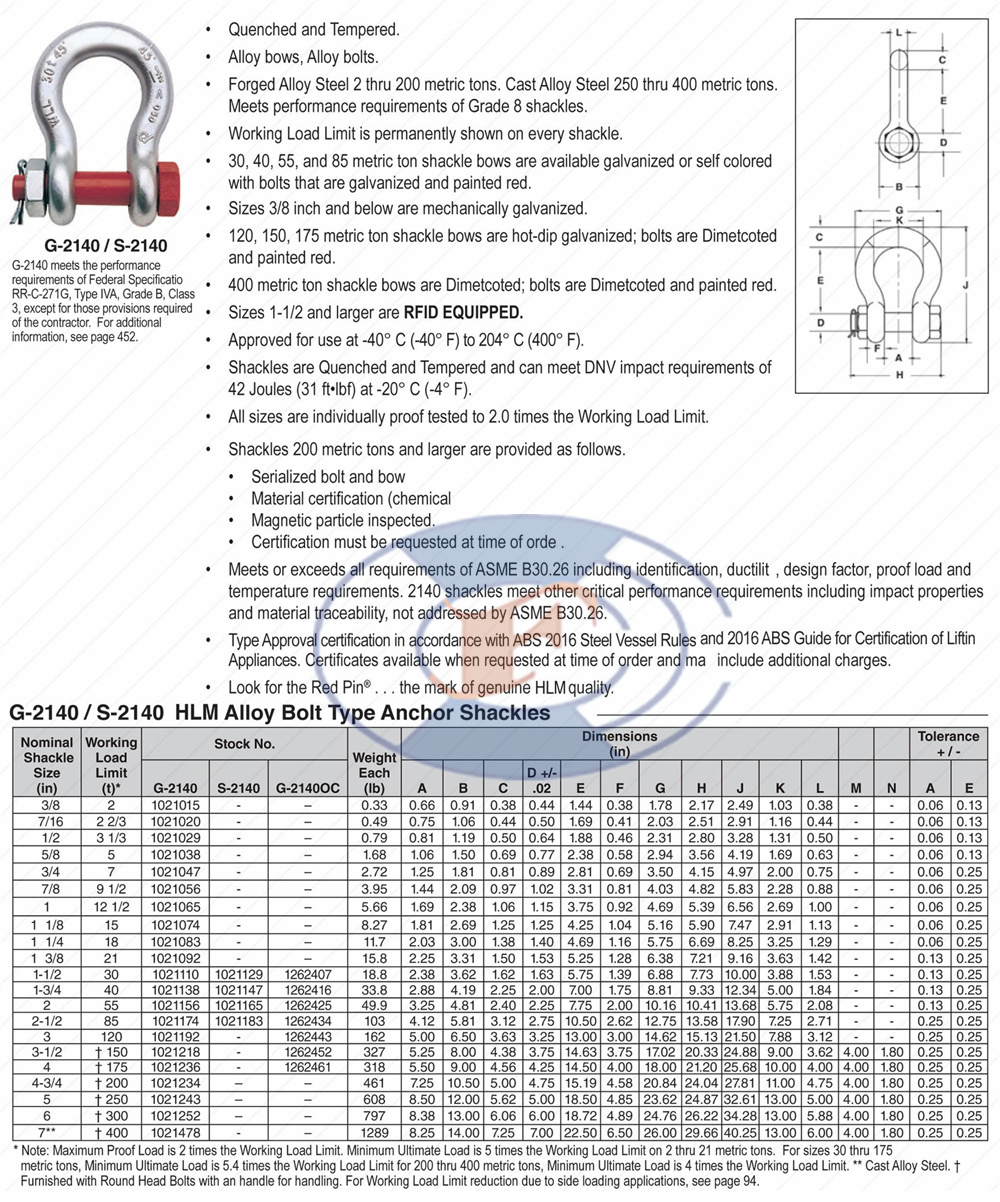

G2140 shackle

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

4. Certified Excellence: CE and More for Reliable Partnerships

Related products

-

J Hook Tow Chain

$1.00