In the dynamic world of construction, logistics, and material handling, the choice of equipment and tools plays a pivotal role in achieving operational excellence. Webbing slings, a versatile tool, offer a range of types and materials to cater to specific needs. In this comprehensive guide, we’ll dive deeper into each webbing sling type, unraveling their unique advantages, disadvantages, and application scenarios. Additionally, we’ll explore the pros and cons of the materials used in webbing slings, providing insights into their optimal usage.

If you need to purchase webbling sling and need webbling sling OEM services, you can contact us. We are a professional supplier.

Exploring Webbing Sling Types

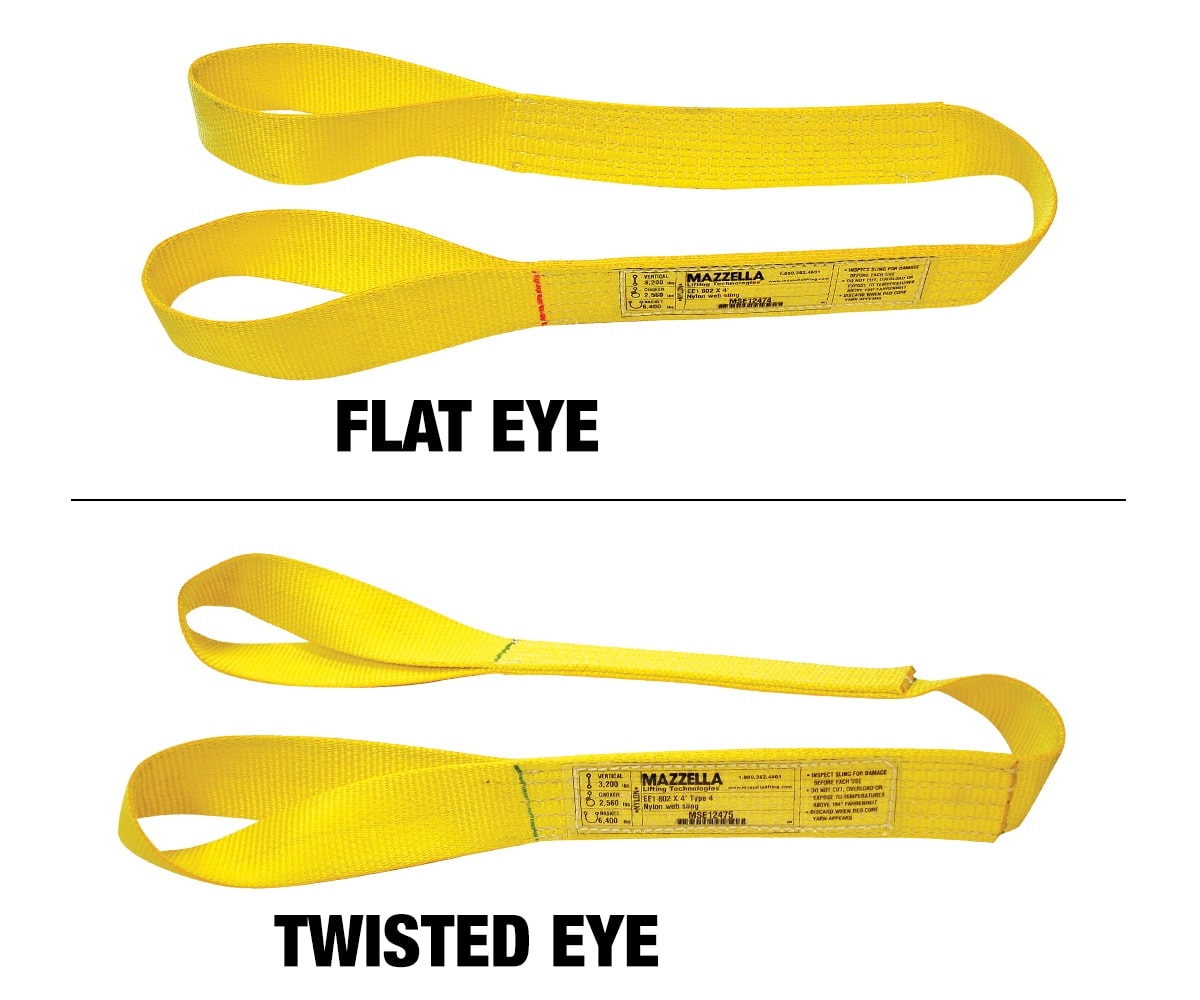

Flat Eye Sling

Advantages:

Versatility: The flat eye design allows this sling to be used in various hitch configurations, making it adaptable to a wide range of lifting needs.

Durability: Flat eye slings are known for their durability and resistance to abrasion, ensuring a longer service life.

Load Protection: The soft, non-abrasive surface of flat eye slings protects delicate loads from damage.

Disadvantages:

Limited Choker Hitch Use: This type is not as suitable for choker hitch applications as other types.

Application Scenarios:

Flat eye slings are excellent for applications that require versatility and load protection. They are widely used in construction and manufacturing.

Twisted Eye Sling

Advantages:

Choker Hitch Compatibility: Twisted eye slings are designed for choker hitch applications, providing an excellent grip on the load.

Load Protection: The soft surface of twisted eye slings safeguards loads from damage.

Durability: They are known for their durability and resistance to abrasion.

Disadvantages:

Limited Versatility: Twisted eye slings are primarily suitable for choker hitch applications, which limits their versatility.

Application Scenarios:

Twisted eye slings are ideal for situations that require secure choker hitch applications, such as handling cylindrical loads in the manufacturing industry.

Endless Webbing Sling

Advantages:

Durability: With no seams or joints, endless slings offer enhanced durability and flexibility.

Load Protection: The soft surface of endless slings protects loads from damage.

Disadvantages:

Limited Load Attachment Options: They may have limited attachment options compared to flat eye or twisted eye slings.

Application Scenarios:

Endless slings are perfect for scenarios where durability and flexibility are essential, such as hoisting irregularly shaped loads in construction.

Reverse Eye Sling

Advantages:

Basket Hitch Compatibility: Reverse eye slings are designed for basket hitch applications, providing excellent load stability.

Load Protection: The soft surface protects loads from damage.

Durability: They are known for their durability and resistance to abrasion.

Disadvantages:

Limited Versatility: Reverse eye slings are primarily suitable for basket hitch applications, which may limit their versatility.

Application Scenarios:

Reverse eye slings are excellent for applications requiring secure basket hitch configurations, such as handling bulky and irregularly shaped loads.

Diving into Webbing Sling Materials

Polyester Webbing Sling

Advantages:

High Strength: Polyester slings offer exceptional strength, making them suitable for heavy lifting.

UV Resistance: They are resistant to UV rays, making them ideal for outdoor applications.

Load Protection: The soft surface protects delicate loads from damage.

Disadvantages:

Moisture Absorption: Polyester slings may not be suitable in damp environments as they can weaken when wet.

Application Scenarios:

Polyester slings are perfect for heavy lifting outdoors, such as in construction and maritime industries.

Nylon Webbing Sling

Advantages:

Excellent Flexibility: Nylon slings provide exceptional flexibility, ideal for applications requiring load protection.

Load Protection: The soft surface protects delicate loads from damage.

Disadvantages:

Moisture Absorption: Nylon slings can weaken when exposed to moisture.

Application Scenarios:

Nylon slings are best suited for scenarios where flexibility and load protection are crucial, such as delicate loads in warehousing.

Polypropylene Webbing Sling

Advantages:

Lightweight: Polypropylene slings are lightweight and economical, making them easy to handle and cost-effective.

Moisture Resistance: They are resistant to moisture, which can be advantageous in certain applications.

Disadvantages:

Reduced Durability: Polypropylene slings may not withstand heavy-duty applications as well as other materials.

Application Scenarios:

Polypropylene slings are suitable for applications where lightweight and moisture resistance are critical, such as material handling in logistics.

Conclusion about Webbing Slings

Understanding the diverse types and materials of webbing slings empowers you to make informed decisions in construction, logistics, and material handling. Each type has its unique strengths, limitations, and optimal usage scenarios, allowing you to select the right tool for the job. Additionally, comprehending the advantages and disadvantages of different webbing sling materials enables you to choose the most suitable option for your specific applications. Whether you’re in construction, logistics, or any industry that relies on material handling, this knowledge is your key to optimizing operations and achieving success.

FAQ about Webbing Slings

1. Are webbing slings safe for lifting heavy loads?

Yes, webbing slings are designed to safely lift and secure heavy loads. They are made from strong materials that can withstand substantial weight, and when used within their specified capacity, they provide reliable load-bearing capabilities.

2. Can I use webbing slings in harsh outdoor conditions, such as in construction sites?

Polyester webbing slings are well-suited for outdoor applications, including construction sites, as they are resistant to UV rays and moisture. They maintain their strength and durability in challenging environmental conditions.

3. What are the advantages of using reverse eye slings for lifting irregularly shaped loads?

Reverse eye slings are ideal for lifting bulky and irregularly shaped loads due to their basket hitch compatibility. They provide excellent load stability and ensure the secure handling of such challenging cargo.

4. In what scenarios should I consider using nylon webbing slings over other materials?

Nylon webbing slings are a top choice when flexibility and load protection are paramount. They are suitable for applications where delicate loads need to be safeguarded, making them a preferred option in warehousing and manufacturing.

5. What are the OEM services you provide as a specialized webbing sling supplier?

As a specialized supplier, we offer OEM (Original Equipment Manufacturer) services, which means we can tailor webbing slings to your specific requirements. You can customize aspects like length, load capacity, and even branding to meet your unique needs.

6. Do polypropylene webbing slings provide adequate durability for heavy-duty applications?

While polypropylene slings are lightweight and economical, they may not be the best choice for heavy-duty applications. Their reduced durability makes them more suitable for lighter material handling scenarios.

7. Can I use endless webbing slings for lifting irregularly shaped or oversized loads?

Yes, endless webbing slings, known for their durability and flexibility, are a great choice for hoisting irregularly shaped or oversized loads. Their seamless design allows them to adapt to various load shapes.

8. Are webbing slings resistant to cutting and abrasion?

Webbing slings are designed to be resistant to abrasion, and their soft surface protects loads from damage. However, they can be susceptible to cutting if used on sharp or abrasive edges. Careful load attachment is crucial.

9. What is the weight range that webbing slings can typically handle?

Webbing slings come in various weight capacities, ranging from light-duty (for smaller loads) to heavy-duty (for larger and heavier loads). The specific weight range depends on the type and material of the webbing sling.

10. Can webbing slings be used for load securing and transportation in addition to lifting?

Yes, webbing slings are versatile and can be used for both lifting and securing loads during transportation. They offer an effective solution for load restraint and are commonly used in logistics and material handling scenarios to ensure cargo remains stable during transit.