Aluminium Wire Rope Ferrule

The Aluminium Wire Rope Ferrule, also known as an aluminum wire rope sleeve or aluminum crimp sleeve, is a specialized fitting used in various applications involving wire ropes. It is specifically designed to create a secure and durable connection between wire rope ends, providing strength and reliability.

The ferrule is typically made of high-quality aluminum alloy, which offers excellent corrosion resistance and lightweight properties. Its construction allows for easy handling and installation, making it a popular choice in industries such as marine, construction, rigging, and general-purpose applications.

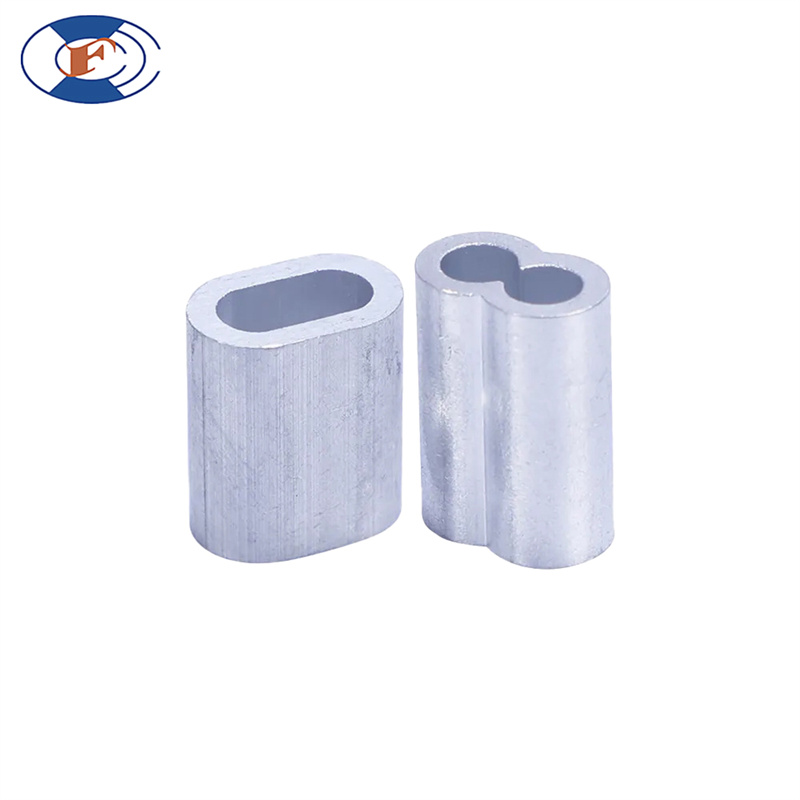

The Aluminium Wire Rope Ferrule consists of a cylindrical sleeve with a smooth inner surface and a series of serrations or grooves on the outer surface. These serrations play a crucial role in gripping and holding the wire rope securely in place once the ferrule is properly crimped.

To install the ferrule, the wire rope is inserted into the sleeve, ensuring that it reaches the desired depth. The ferrule is then compressed or crimped using specialized tools such as wire rope crimpers or hydraulic presses. This compression process deforms the ferrule, causing the serrations to bite into the wire rope strands and create a strong mechanical connection.

The resulting connection formed by the Aluminium Wire Rope Ferrule is known for its high tensile strength and resistance to slippage. It effectively distributes the load evenly across the wire rope, minimizing stress concentrations and enhancing overall stability.

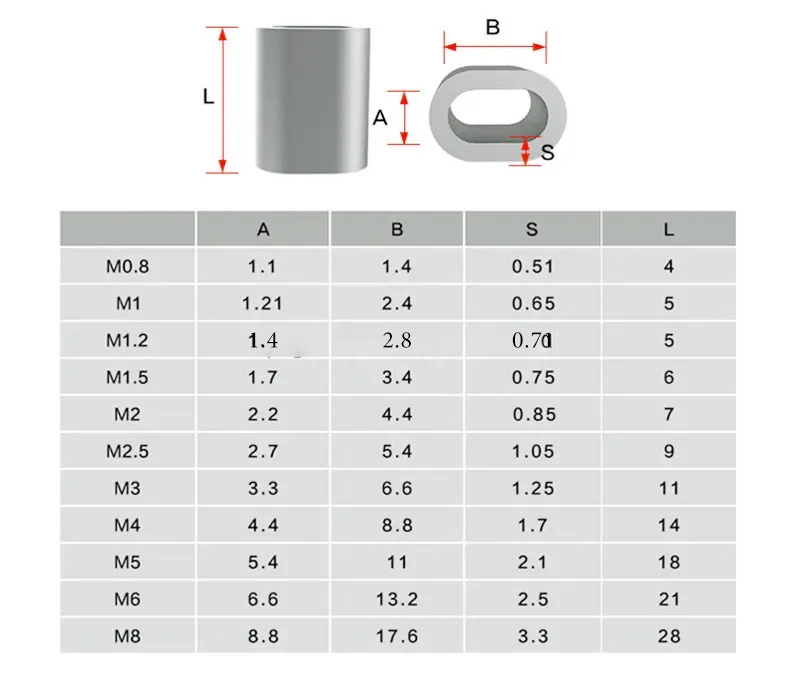

Aluminium Wire Rope Ferrules are available in various sizes to accommodate different wire rope diameters. It is essential to choose the appropriate ferrule size that matches the wire rope to ensure a proper fit and maximum holding strength.

One of the advantages of using Aluminium Wire Rope Ferrules is their compatibility with both galvanized and stainless steel wire ropes. They can be used with various types of wire rope configurations, including single-strand, multi-strand, and compacted wire ropes.

It is important to note that proper installation techniques and tools should be followed to ensure a secure and reliable connection. Following manufacturer guidelines and industry best practices for crimping and termination procedures is crucial to maintain the integrity and strength of the wire rope assembly.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

4. Certified Excellence: CE and More for Reliable Partnerships

Related products

-

Wire Rope Tube Thimble

$1.00 -

Fist Grip Clamps

$1.00 -

Chain with Grab Hooks

$1.00 -

7×19 Wire Rope

$1.00