Introducing the Double Waler Bracket from H&F, your go-to solution for high-strength and reliable concrete formwork. Designed to provide exceptional support and stability, our Double Waler Bracket is an essential component for any construction project requiring reinforced concrete structures. Manufactured using premium-grade materials, this bracket ensures durability and long-lasting performance, making it a valuable addition to your construction toolkit.

Our Double Waler Bracket is expertly engineered to work seamlessly with snap ties, providing a robust and secure connection that enhances the overall stability of your formwork system. Whether you’re working on commercial, residential, or industrial construction projects, our bracket is designed to meet the highest standards of safety and efficiency.

Key Features:

- High-Strength Material: Made from high-quality steel for maximum durability and load-bearing capacity.

- Corrosion-Resistant Coating: Features a protective coating to withstand harsh environmental conditions.

- Easy Installation: User-friendly design allows for quick and hassle-free setup, saving you time and labor costs.

- Versatile Application: Suitable for a wide range of concrete formwork applications, including walls, foundations, and columns.

- Enhanced Stability: Provides superior support when used with snap ties, ensuring your formwork remains securely in place.

About the Product and Applications

What is a Double Waler Bracket? A Double Waler Bracket is a crucial component in the concrete formwork system. It is used to reinforce and stabilize the formwork, ensuring that it can withstand the pressure exerted by the wet concrete. This bracket is designed to hold two walers (horizontal supports) in place, providing additional strength and rigidity to the formwork structure.

Applications:

- Wall Formwork: Ideal for use in creating strong and stable wall forms.

- Foundation Formwork: Ensures the integrity and durability of foundation structures.

- Column Formwork: Provides reliable support for column formwork systems.

Using Double Waler Bracket with Snap Ties: Snap ties are essential for maintaining the spacing between formwork panels and preventing them from bulging under the pressure of the concrete. When used in conjunction with double waler brackets, snap ties provide a secure and stable formwork system. The snap ties are inserted through the formwork and secured with the double waler bracket, which helps distribute the load and keep the formwork panels aligned and stable during the concrete pouring process.

Why Choose H&F?

At H&F, we are dedicated to providing high-quality construction products that meet the demands of our customers. Our Double Waler Bracket is manufactured to the highest standards, ensuring reliability and performance on every job site. We offer competitive pricing, exceptional customer service, and fast delivery times to meet your project deadlines.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

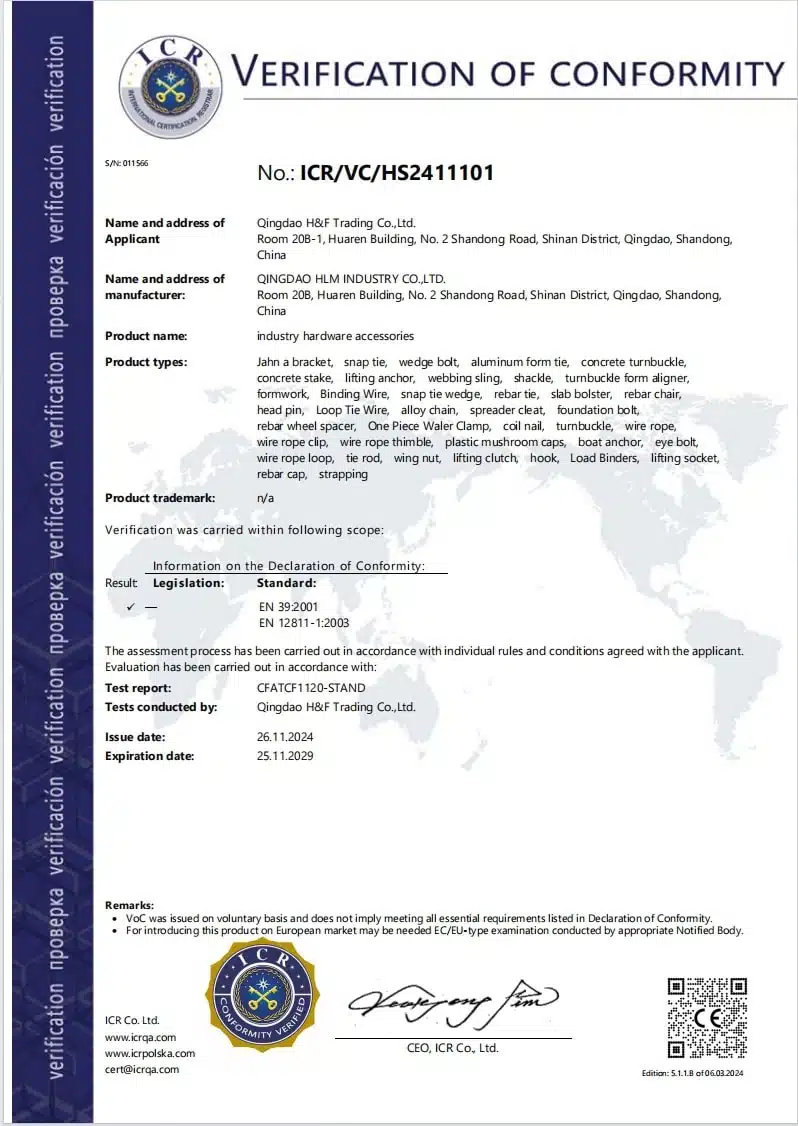

4. Certified Excellence: CE and More for Reliable Partnerships

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.