Sandwich Panel Erection Anchor

In construction, sandwich panel erection anchors are very important tools that make the lifting and installation of sandwich panels both safe and efficient. You would want to focus on three key things as a buyer: reliability, compatibility with different panel types, and strong load-bearing capacity. Here at Qingdao H&F, we have spent 20 years perfecting our approach: offering personalized customer service, quicker delivery times, and detailed quality reports for every order shipped. We are committed to giving our clients worldwide the smoothest possible purchasing experience.

The construction industry’s growing use of prefabricated components has made sandwich panel erection anchors more important than ever. These specialized tools are crucial for safely lifting, positioning, and installing sandwich panels in walls, roofs, and facades. Whether you’re manufacturing these anchors or using them on-site, understanding their varieties, uses, and performance factors is essential.

The Function and Importance of Sandwich Panel Erection Anchors

Safety and efficiency during installation are the primary functions of sandwich panel erection anchors. These tools create reliable attachment points for lifting equipment, significantly reducing the risks of handling heavy panels. On projects where time matters and precision is crucial, these anchors simplify complex logistics while meeting strict safety requirements.

These anchors do more than just lift – they help ensure panels line up correctly and stay properly positioned, preventing structural stress and misalignment during installation. This precision is particularly crucial in large industrial and commercial builds, where consistent performance across all components can make or break a project. Your choice of anchor type directly impacts how successful your project will be.

Types and Applications of Sandwich Panel Erection Anchors

Construction teams can choose from several anchor types, each designed for specific panel weights, designs, and installation needs. Some work best with lighter panels, while others are built to handle reinforced, heavier designs.

Mechanical anchors are popular thanks to their flexibility and simple installation process. Construction teams value them for spreading loads evenly during lifting. For tougher environments requiring extra durability, welded anchors offer enhanced strength.

You’ll also find embedded anchors, which manufacturers install directly into panels during production. These are perfect for projects needing smooth integration with minimal adjustments on-site. Regardless of type, selecting the right anchor requires careful consideration of your project’s needs – from load requirements to environmental conditions and industry standards.

These anchors aren’t limited to any single industry. You’ll find them at work in warehouse construction, factory builds, office developments, and even homes. Their adaptability to different panel sizes and materials makes them valuable for both small projects and major developments.

Factors Influencing the Selection of Sandwich Panel Erection Anchors

Choosing the right erection anchor involves several crucial considerations. Load-bearing capacity tops the list – you need to know exactly how much weight your anchor can safely handle. This requires precise calculations based on your panel specifications and materials to prevent overloading.

Material quality matters tremendously. Most manufacturers choose high-strength steel for its superior tensile strength and durability. If you’re building in humid areas or near the coast, corrosion resistance becomes critical. Many contractors opt for galvanized or coated anchors to extend their service life.

Installation ease and compatibility with standard lifting equipment can significantly impact your project’s timeline and budget. The right anchors will work smoothly with your existing systems, cutting down on labor costs and speeding up construction. Meeting international safety standards isn’t optional – it’s essential for ensuring regulatory compliance and project success.

At Qingdao H&F, these factors guide our product sourcing and delivery. We’ve built our product range to meet diverse global requirements, backing everything with thorough quality checks and performance testing. This ensures you get exactly what your project needs.

Enhancing the Value of Sandwich Panel Erection Anchors Through Expert Support

Getting the most from your sandwich panel erection anchors isn’t just about the hardware – it’s about the support behind it. Our team at Qingdao H&F believes in clear communication and expert guidance. We work closely with each client to understand their specific needs, providing targeted recommendations for optimal performance.

We know construction projects can’t afford delays, which is why we’ve optimized our delivery process. Through efficient supply chain management and strategic partnerships, we ensure your anchors arrive when you need them, wherever you are.

Every shipment comes with detailed quality inspection reports, giving you complete visibility into product specifications and performance data. This transparency reflects our commitment to delivering excellence.

Looking Ahead: The Future of Sandwich Panel Erection Anchors

The construction industry keeps evolving, and panel installation techniques are no exception. We’re seeing exciting developments in anchor technology, including stronger but lighter materials. The future might bring smart anchors with built-in sensors to monitor stress loads and alignment, taking safety and efficiency to new levels.

At Qingdao H&F, we stay ahead of these industry shifts. By keeping up with the latest developments, we ensure our clients always have access to cutting-edge solutions. We combine innovative products with customer-focused service to maintain our position as a market leader in panel erection anchor solutions.

In closing, sandwich panel erection anchors remain fundamental to successful modern construction. Their role in enabling safe, efficient installation makes them invaluable to builders and contractors alike. At Qingdao H&F, we take pride in being a reliable partner in this dynamic field, delivering quality and excellence to clients worldwide.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

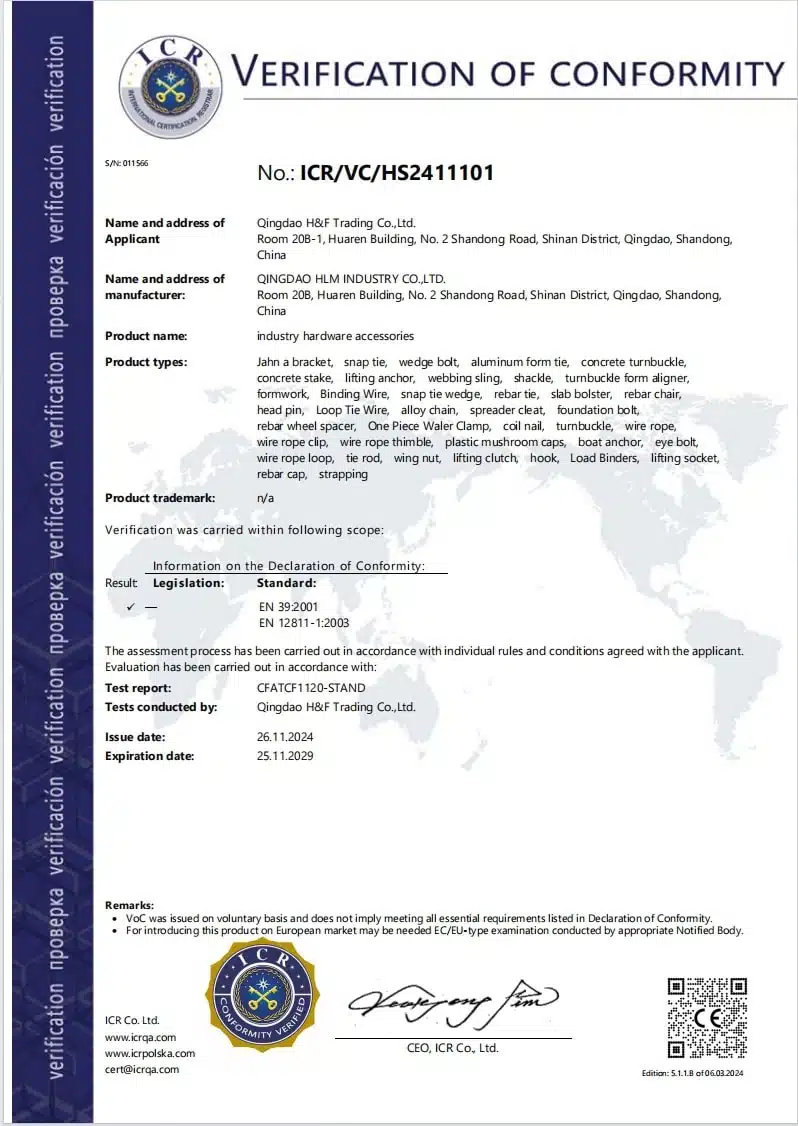

4. Certified Excellence: CE and More for Reliable Partnerships

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Related products

-

Hook Lift Anchor

$0.01 -

Crown Foot Anchor

$0.01