Lifting clutch is an essential tool in the construction industry for lifting and handling precast concrete elements. In this article, we will explore what precast lifting clutches are, how they are used, their connection with lifting anchors, safety considerations, choosing the right supplier, and answer frequently asked questions to provide a comprehensive guide on using lifting clutches effectively.

What is Precast Lifting Clutch?

Material and Construction:

Precast lifting clutches are typically constructed from high-strength steel to withstand the rigors of lifting heavy loads. The steel construction ensures durability and reliability, making them suitable for use in various construction environments. The clutches are engineered to meet specific load-bearing capacities, ensuring they can safely lift and transport precast concrete elements of various sizes and weights.

Design and Functionality:

The design of precast lifting clutches is characterized by a robust and compact structure, featuring a hook or loop mechanism that securely attaches to lifting anchors embedded in precast concrete elements. This attachment ensures a stable connection between the lifting clutch and the concrete element, allowing for safe lifting and handling.

Application Scenarios:

Precast lifting clutches are widely used in a range of construction applications, including:

Precast concrete manufacturing plants: Lifting clutches are used during the production process to lift and transport precast concrete elements within the manufacturing facility.

Construction sites: Lifting clutches are essential for lifting and installing precast concrete elements at construction sites, including buildings, bridges, parking structures, and infrastructure projects.

Retrofit and renovation projects: Lifting clutches are also used in retrofit and renovation projects involving the installation of precast concrete components to existing structures.

Benefits of Using Precast Lifting Clutches:

Safety: Precast lifting clutches are designed to ensure secure attachment to precast concrete elements, minimizing the risk of accidents or mishaps during lifting operations.

Efficiency: The use of lifting clutches streamlines the lifting and handling process, allowing for faster and more efficient installation of precast concrete elements.

Versatility: Precast lifting clutches are compatible with various types of lifting equipment, including cranes, hoists, and forklifts, making them suitable for a wide range of construction applications.

Cost-effectiveness: By facilitating faster installation times and minimizing the need for manual labor, precast lifting clutches help reduce overall project costs.

Lifting Clutch and Lifting System

In construction projects involving the lifting and handling of precast concrete elements, the connection between lifting clutches and lifting anchors is crucial for ensuring safe and efficient lifting operations. Various types of lifting anchors, including Lifting Pin Eye Anchors, Dog Bone Anchors, Utility Lifting Anchors, and Forged Erection Anchors with Shear Plates, are commonly used in conjunction with lifting clutches to provide a reliable lifting solution. Let’s explore how these lifting anchors connect with lifting clutches:

Lifting Pin Eye Anchor:

Lifting Pin Eye Anchors feature a pin eye design that provides a secure connection point for attaching lifting clutches. The lifting clutch is positioned over the pin eye of the anchor, and a locking mechanism ensures a tight and secure fit, allowing for safe lifting and handling of precast concrete elements.

Dog Bone Anchor:

Dog Bone Anchors, also known as spread anchors, are designed with multiple attachment points for lifting clutches. The lifting clutch is attached to the dog bone anchor by inserting its hooks or loops into the designated attachment points, ensuring a stable and evenly distributed load during lifting operations.

Utility Lifting Anchor:

Utility Lifting Anchors are versatile lifting devices commonly used in precast concrete applications. These anchors feature a variety of attachment points, including loops, eyes, or holes, for connecting with lifting clutches. The lifting clutch is securely attached to the utility lifting anchor, allowing for safe and efficient lifting of precast concrete elements.

Forged Erection Anchor with Shear Plate:

Forged Erection Anchors with Shear Plates are robust lifting anchors designed for heavy-duty lifting applications. These anchors feature a shear plate that provides additional reinforcement and stability during lifting operations. The lifting clutch is attached to the forged erection anchor by engaging with the shear plate, ensuring a secure connection for lifting heavy precast concrete elements.

How To Use Lifting Clutch

Inspect the Lifting Clutch: Before use, visually inspect the lifting clutch for any signs of damage or wear. Ensure that all components are in good condition and securely attached.

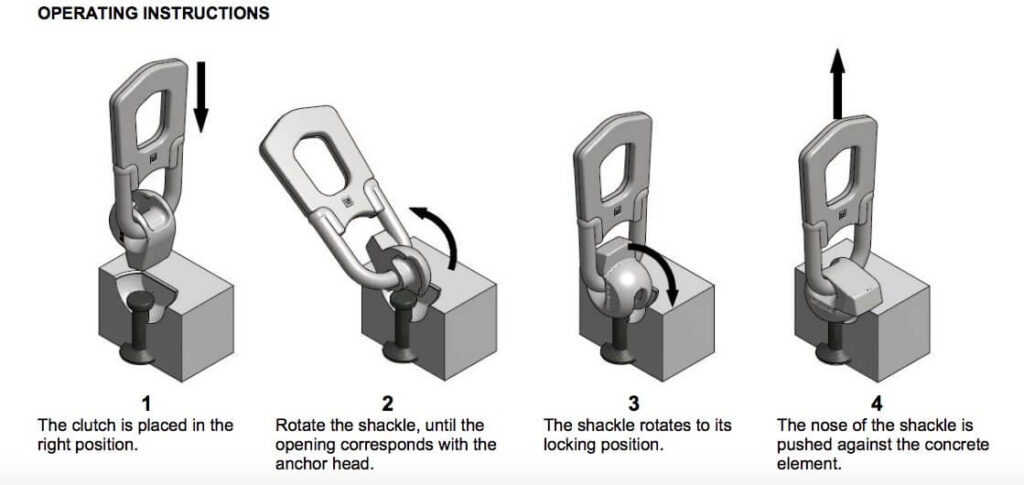

Attach the Lifting Clutch: Position the lifting clutch over the lifting anchor embedded in the precast concrete element. Ensure that the lifting clutch engages securely with the lifting anchor.

Lift the Load: Once the lifting clutch is securely attached, use appropriate lifting equipment such as a crane or hoist to lift the precast concrete element safely.

Monitor During Lifting: Continuously monitor the lifting process to ensure stability and safety. Avoid sudden movements or jerks that could compromise the integrity of the lift.

Lower the Load: After completing the lifting operation, carefully lower the precast concrete element to its intended location. Remove the lifting clutch once the load is safely positioned.

How to Inspect and Maintain the Lifting Eye and Lifting Clutch Regular for Safety?

Regular inspection and maintenance of lifting clutches are essential to ensure safe operation and prevent accidents. Here are some key steps to inspect and maintain lifting clutches:

Visual Inspection: Regularly inspect the lifting clutch for signs of wear, corrosion, or damage. Pay attention to welds, hinges, and load-bearing components.

Load Testing: Periodically conduct load testing to ensure that the lifting clutch meets the required load-bearing capacity. Follow manufacturer guidelines for load testing procedures.

Cleaning and Lubrication: Keep the lifting clutch clean and free from debris. Apply lubrication to moving parts to prevent rust and ensure smooth operation.

Storage: Store lifting clutches in a dry, well-ventilated area away from corrosive substances and extreme temperatures.

Replacement of Damaged Parts: If any part of the lifting clutch shows signs of damage or wear beyond repair, replace it promptly with genuine manufacturer-approved parts.

Which Lifting Clutch Supplier Should You Choose?

When choosing a lifting clutch supplier, it’s essential to consider factors such as quality, reliability, and customer service. Qingdao H&F is a professional lifting clutch supplier known for its high-quality products and excellent customer service. Our lifting clutches undergo rigorous quality inspections before shipment to ensure reliability and safety. With a stable shipping cycle and dedicated customer service team, we strive to provide the most professional and high-quality service to our customers.

Conclusion about Lifting Clutch

Lifting clutches are indispensable tools for handling precast concrete elements in construction projects. By understanding how to use them safely and effectively, conducting regular inspections and maintenance, and choosing a reliable supplier, construction professionals can ensure smooth and efficient lifting operations.

FAQ about Lifting Clutch

1. How do I determine the correct lifting clutch capacity for my project?

The lifting clutch capacity should be determined based on the weight of the precast concrete element to be lifted. Refer to manufacturer specifications and consult with lifting experts to ensure the appropriate lifting clutch capacity for your project.

2. Can lifting clutches be reused?

Yes, lifting clutches can be reused multiple times if they are well-maintained and not subjected to excessive wear or damage.

3. Are there different types of lifting clutches available?

Yes, lifting clutches come in various designs and capacities to suit different lifting requirements. Common types include straight loop clutches, recessed lifting clutches, and adjustable lifting clutches.

4. What safety precautions should I take when using lifting clutches?

Always follow manufacturer guidelines for safe use and operation of lifting clutches. Ensure proper inspection of equipment, use appropriate lifting equipment, and provide adequate training for personnel involved in lifting operations.

5. Can lifting clutches be used in harsh environments?

Lifting clutches are designed to withstand harsh environments, but proper maintenance and inspection are essential to ensure optimal performance and longevity in challenging conditions.

6. How do I know if a lifting clutch is compatible with my lifting equipment?

Check the specifications of both the lifting clutch and your lifting equipment to ensure compatibility. Consult with lifting equipment manufacturers or suppliers for guidance if needed.

7. What should I do if a lifting clutch fails during a lift?

If a lifting clutch fails during a lift, immediately stop the lifting operation and safely lower the load to the ground. Inspect the lifting clutch for damage and replace it if necessary before resuming lifting operations.

8. Are there any regulations or standards for using lifting clutches?

Yes, there are regulations and standards governing the use of lifting equipment, including lifting clutches. Familiarize yourself with applicable regulations and ensure compliance with safety standards to prevent accidents and ensure workplace safety.

9. Can lifting clutches be used for horizontal lifting?

Lifting clutches are primarily designed for vertical lifting applications. Using them for horizontal lifting may compromise safety and is not recommended.

10. How do I store lifting clutches when not in use?

Store lifting clutches in a dry, well-ventilated area away from corrosive substances and extreme temperatures. Proper storage helps prevent damage and extends the lifespan of lifting clutches.