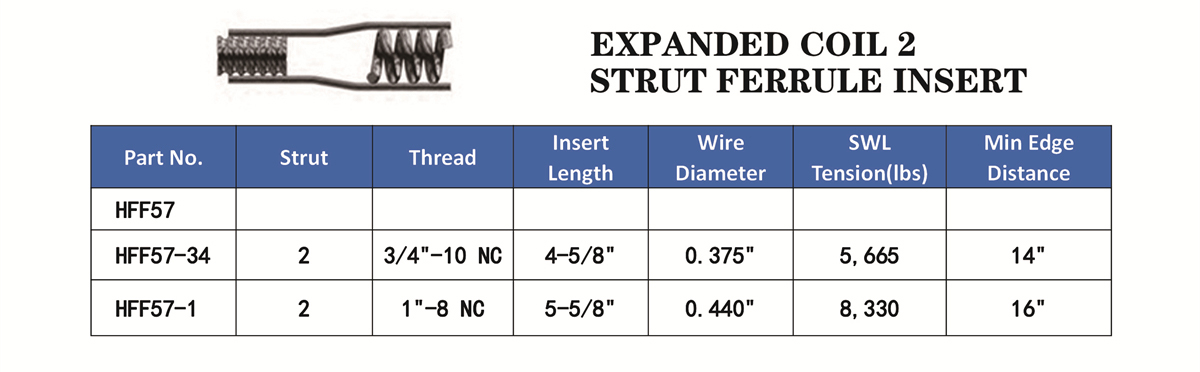

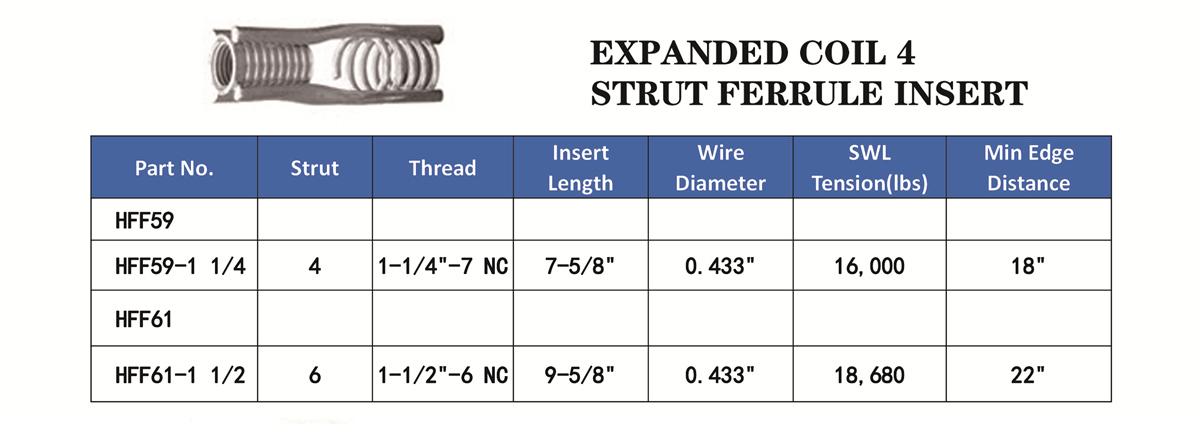

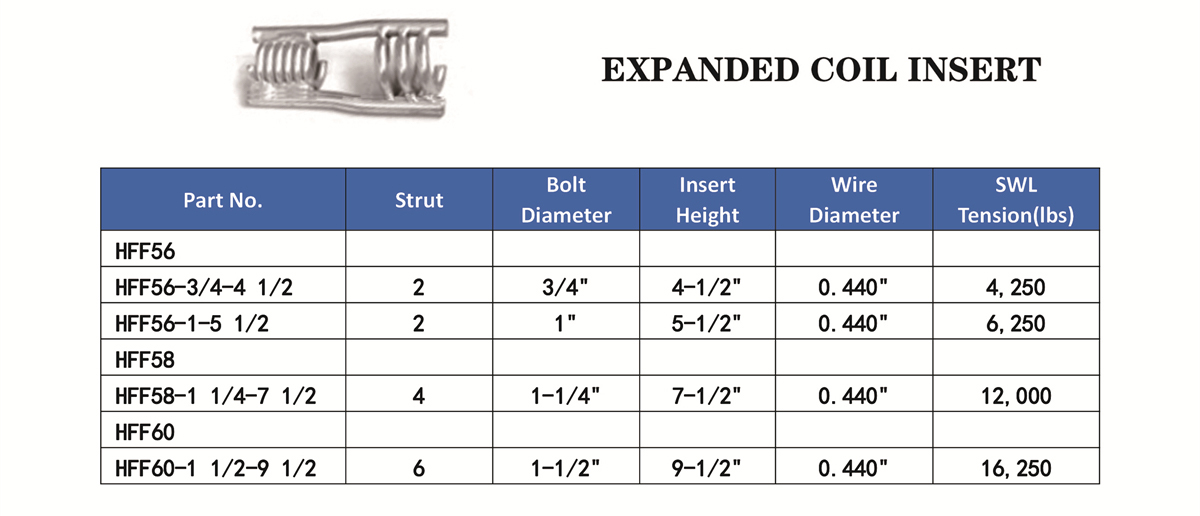

Expanded Coil Ferrule Insert

An Expanded Coil Ferrule Insert is a type of fitting used in piping systems that helps to connect two pipes together. It consists of a small, tapered metal tube with a series of coils or ridges on the outside. The coils allow the insert to grip the inside of the pipe securely, creating a tight seal.

The Expanded Coil Ferrule Insert is a type of concrete hardware used in construction to provide a secure and reliable anchor point for various types of equipment, fixtures, and fittings. It consists of a coiled wire that is embedded into the concrete structure during the pouring process, creating a strong and durable anchor point that can withstand heavy loads and extreme conditions.

The Expanded Coil Ferrule Insert is typically made of high-strength, corrosion-resistant steel or stainless steel, and is designed to provide maximum strength and durability. It is commonly used in applications such as concrete forms, tilt-up walls, precast panels, bridge decks, and other structural components.

One of the key advantages of the Expanded Coil Ferrule Insert is its unique design, which allows it to expand and grip the surrounding concrete as it is installed. This creates a secure and reliable anchor point that is less likely to pull out or fail under heavy loads. Additionally, its low profile design makes it an ideal choice for applications where space is limited.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

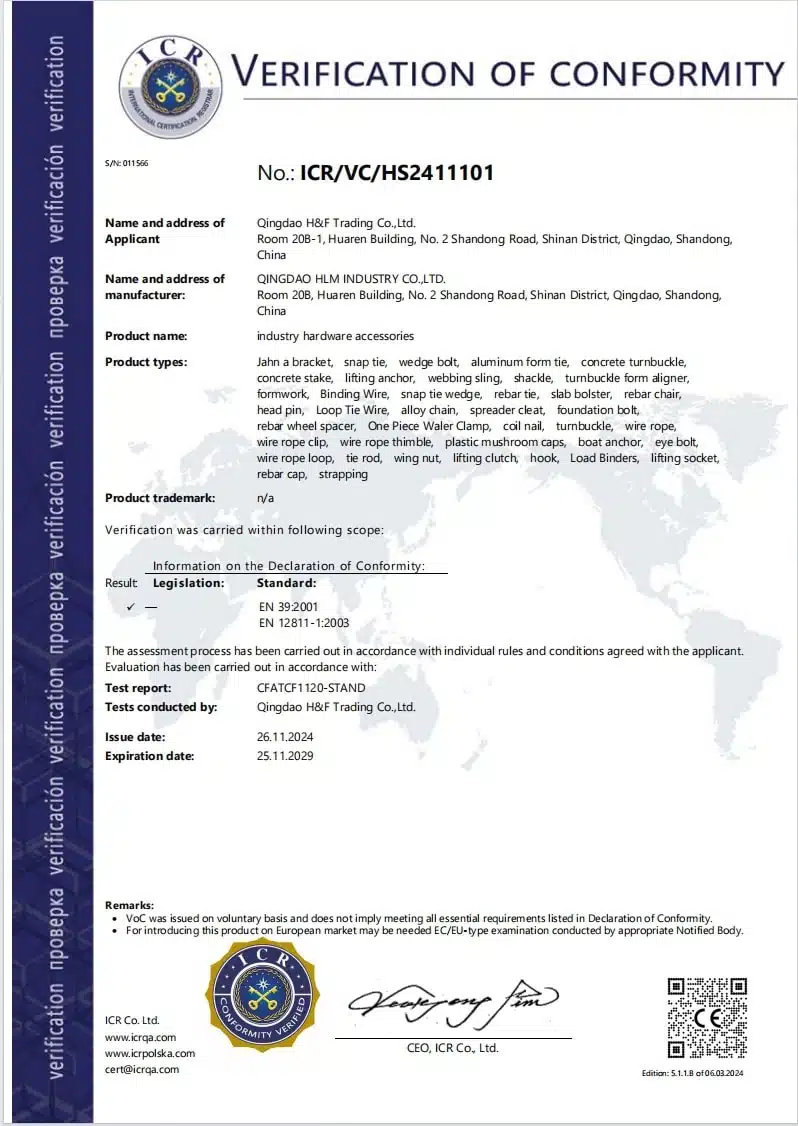

4. Certified Excellence: CE and More for Reliable Partnerships

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Related products

-

Concrete Form Pins

$0.01 -

Cast-in Channels

$0.01