Fixing Sockets with Cross Pin | Bent Tail | Wavy Tail

Concrete forming fixing sockets are a type of construction accessory used in the concrete forming process. They are typically made of steel and used to secure formwork panels or other forming materials in place during the pouring and setting of concrete.

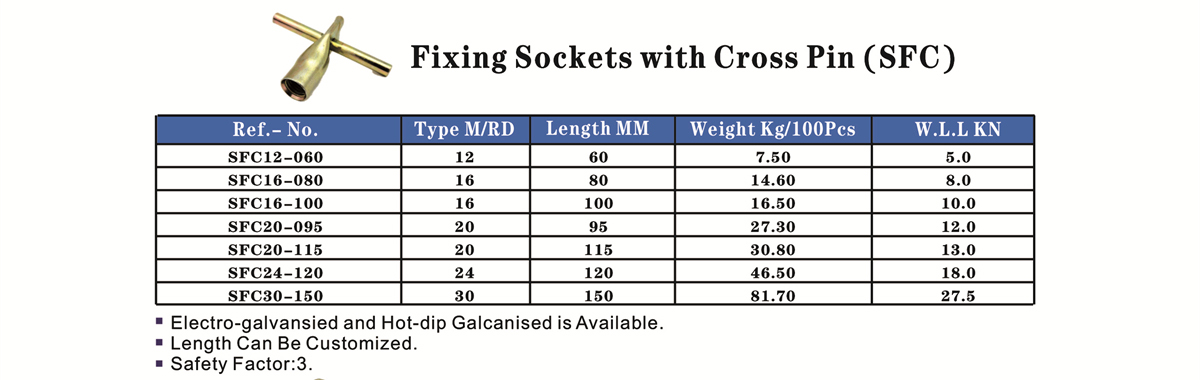

Fixing Sockets with Cross Pin

Fixing sockets with cross pins is a method of connecting two parts or components together. It involves the use of a socket, which is a hollow cylinder with a hole in the center, and a cross pin, which is a cylindrical pin with four arms that extend out from the center. The cross pin is inserted into the hole in the socket, and the arms of the pin are then aligned with corresponding holes in the components that are to be connected.

Once the cross pin is in place, it is secured using a fastener such as a nut or a cotter pin. This creates a strong and reliable connection between the two components, and allows for easy disassembly and reassembly if necessary.

Fixing sockets with cross pins are commonly used in mechanical and automotive applications, as well as in furniture assembly and other industries where a secure and easily removable connection is required.

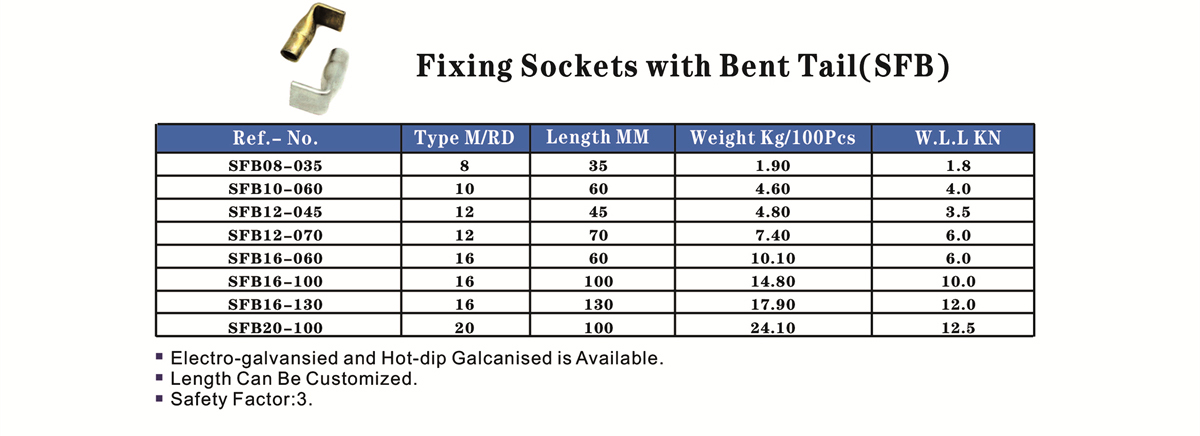

Fixing Sockets with Bent Tail

Sockets with bent tails refer to the sockets that have been damaged due to excessive force or pressure applied to them, causing the tail or stem of the socket to become bent or misaligned. This can cause problems with the connection between the socket and the electrical outlet, resulting in poor connectivity, sparking, and even the risk of electrical fires.

Fixing sockets with bent tails is a common electrical repair task that requires some basic knowledge of electrical wiring and safety procedures. If you’re not confident in your abilities to fix a damaged socket, it’s best to hire a licensed electrician to do the job for you.

However, if you’re up for the task, the process of fixing a socket with a bent tail involves several steps, including turning off the power to the outlet, removing the damaged socket, replacing it with a new socket, and testing the connection to ensure it’s working properly. By following the correct procedures and safety precautions, you can fix a damaged socket and ensure the safety of your electrical system.

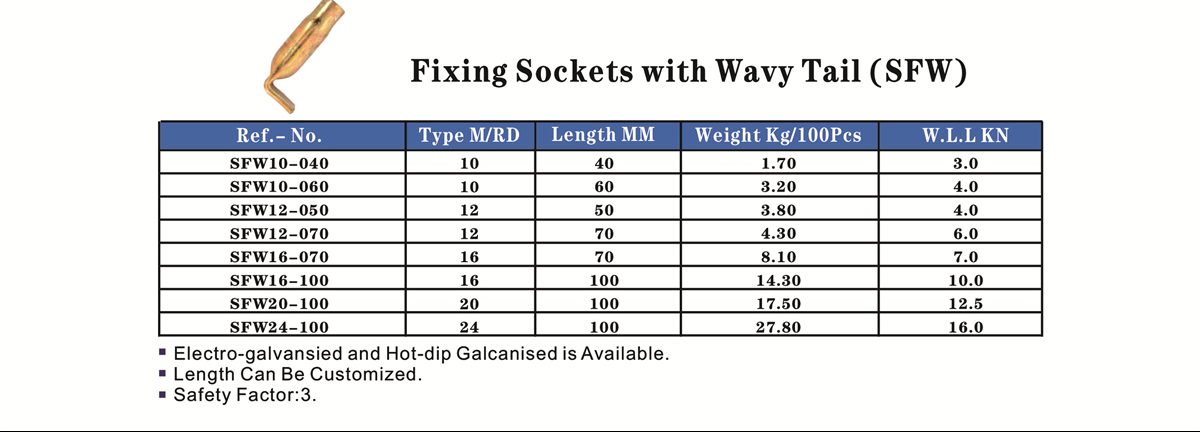

Fixing Sockets with Wavy Tail

Fixing sockets with wavy tail are a type of concrete forming accessory used in construction projects. They are typically made of steel and are used to secure formwork panels or other concrete forming materials in place during the pouring and setting of concrete.

The wavy tail design of these fixing sockets allows for easy attachment and removal of the formwork panels without the need for additional tools or hardware. This feature makes them particularly useful for projects where time and efficiency are important factors.

The fixing sockets with wavy tail are available in various sizes and can be used with different types of formwork systems, including plywood, steel, and aluminum forms. They are designed to provide a secure and stable connection between the formwork and the concrete structure, ensuring that the final product is strong, durable, and meets all necessary safety standards.

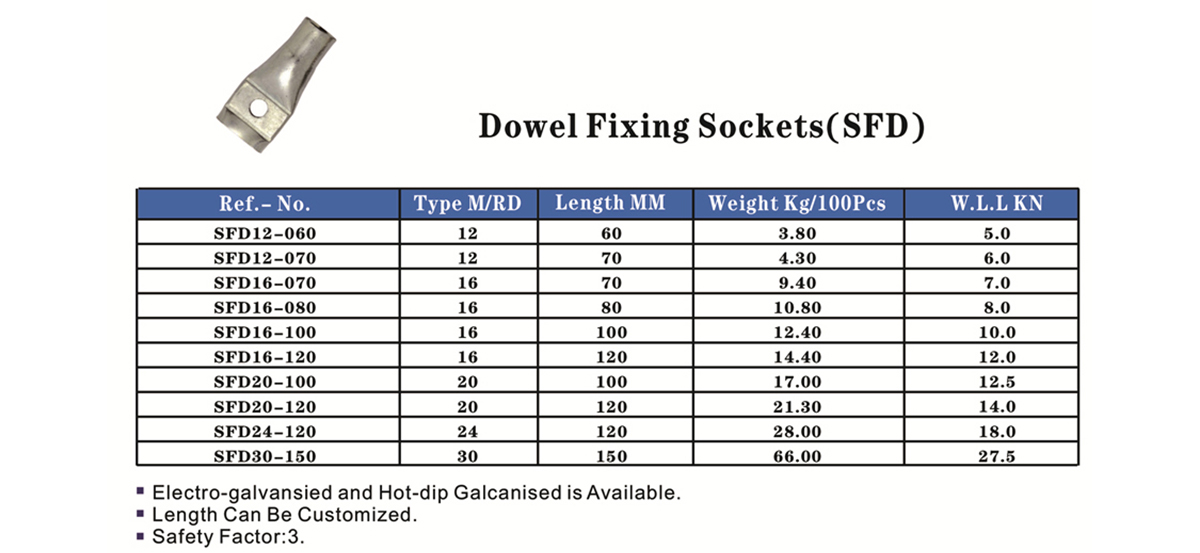

Fixing Sockets Dowel:

You can click here to view the details of Fixing Sockets Dowel.Fixing Sockets Dowel

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

4. Certified Excellence: CE and More for Reliable Partnerships

Related products

-

Z Tie Holder

$1.00