Hall Anchor

The hall anchor provides a reliable solution for securing formwork in concrete construction, combining robust stability with straightforward installation. Crafted from high-grade steel and rigorously tested, this essential component adapts to diverse structural requirements with customizable thread lengths and load capacities.

What Is a Hall Anchor?

A hall anchor serves as the connecting point between formwork and the supporting structure, ensuring that panels remain fixed during concrete pouring. Unlike simple hooks or clamps, the hall anchor features threaded sections and a seating flange that work in tandem to transfer loads evenly. Designers appreciate how a well-chosen hall anchor reduces formwork movement, minimizes alignment errors, and ultimately contributes to a more uniform concrete finish. In practice, architects and contractors rely on hall anchor performance data—such as pull‑out resistance and embedment depth—to verify that their formwork system meets both safety codes and on‑site demands.

| Nominal Weight(kg) | L | L1 | L2 | H | H1 | B1 |

|---|---|---|---|---|---|---|

| 40 | 430 | 303 | 557 | 67 | 303 | 198 |

| 60 | 492 | 347 | 637 | 76 | 347 | 227 |

| 100 | 540 | 378 | 750 | 91 | 395 | 230 |

| 125 | 580 | 405 | 810 | 97 | 425 | 248 |

| 150 | 612 | 432 | 855 | 104 | 452 | 264 |

| 180 | 650 | 459 | 910 | 111 | 480 | 280 |

| 240 | 720 | 510 | 1010 | 122 | 530 | 310 |

| 280 | 760 | 534 | 1060 | 130 | 560 | 325 |

| 300 | 770 | 540 | 1080 | 131 | 570 | 331 |

| 320 | 790 | 560 | 1100 | 132 | 580 | 338 |

| 360 | 820 | 580 | 1150 | 139 | 610 | 353 |

| 420 | 860 | 610 | 1200 | 146 | 640 | 370 |

| 480 | 900 | 640 | 1260 | 153 | 670 | 387 |

| 570 | 1042 | 732 | 1355 | 161 | 732 | 481 |

| 660 | 1096 | 769 | 1422 | 169 | 769 | 506 |

| 780 | 1170 | 820 | 1506 | 180 | 820 | 540 |

| 900 | 1220 | 855 | 1580 | 188 | 855 | 560 |

| 1020 | 1260 | 885 | 1645 | 194 | 885 | 580 |

| 1140 | 1319 | 916 | 1705 | 206 | 926 | 605 |

| 1290 | 1378 | 965 | 1778 | 211 | 965 | 630 |

| 2100 | 1651 | 1120 | 2093 | 245 | 1120 | 732 |

| 2850 | 1890 | 1253 | 2318 | 271 | 1253 | 822 |

| 3540 | 2032 | 1345 | 2480 | 294 | 1345 | 880 |

| 4320 | 2171 | 1435 | 2695 | 316 | 1435 | 943 |

| 4890 | 2263 | 1498 | 2769 | 329 | 1498 | 984 |

| 5000 | 2317 | 1510 | 2800 | 332 | 1510 | 992 |

| 6450 | 2340 | 1644 | 3037 | 361 | 1644 | 1080 |

| 7800 | 2493 | 1750 | 3235 | 385 | 1750 | 1152 |

| 8500 | 2565 | 1800 | 3355 | 395 | 1800 | 1184 |

| 10500 | 2752 | 1934 | 3571 | 425 | 1934 | 1273 |

| 12900 | 2947 | 2072 | 3824 | 455 | 2072 | 1363 |

| 13500 | 2992 | 2104 | 3882 | 462 | 2104 | 1384 |

| 14700 | 3078 | 2165 | 3994 | 476 | 2165 | 1424 |

| 16900 | 3225 | 2268 | 4184 | 498 | 2268 | 1492 |

| 23000 | 3573 | 2514 | 4631 | 551 | 2514 | 1654 |

| 35500 | 4132 | 2903 | 5363 | 637 | 2903 | 1906 |

| 46000 | 4505 | 3165 | 5847 | 695 | 3165 | 2078 |

Materials and Construction

Most hall anchors consist of carbon steel (grade Q235 or Q345), sometimes upgraded to stainless steel (AISI 304/316) for corrosive environments. The steel rod undergoes precision turning and thread rolling, while the flange is stamped from sheet steel and heat-treated to relieve stress. To combat oxidation, anchors are hot-dip galvanized to a minimum coating thickness of 80 µm, or electroplated for tighter thread tolerances. Interestingly, specialty variants feature duplex coatings—zinc followed by epoxy—for extreme durability. By controlling metallurgical composition and surface finish, manufacturers guarantee consistent tensile strength (up to 550 MPa) and predictable deformation characteristics under load.

Applications of Hall Anchors

In residential concrete floors, the hall anchor locks edge forms in place to prevent lateral creep when concrete reaches its fluid state. Commercial high‑rise projects utilize heavy‑duty hall anchors to withstand dynamic forces during high‑speed pours. Bridge construction often calls for adjustable anchors that accommodate varying form thicknesses, ensuring a snug fit even when crews swap panels of different depths. Moreover, in precast yards, hall anchors enable repeated panel assembly and disassembly without thread wear—thanks to replaceable flange sleeves. For instance, casting beams and columns relies on anchor consistency to align cavities, while slab-on-grade work demands anchors that resist pull‑through as concrete shrinks.

Types and Variations

Standard hall anchors feature a fixed thread length—commonly 150 mm, 200 mm, or 300 mm—paired with a flat seating flange of 50 mm diameter. Heavy‑duty models offer thicker flanges (up to 70 mm) and longer threads (400 mm) for deep embeds. Adjustable‑length anchors incorporate two interlocking rods, letting installers fine‑tune embedment from the site rather than ordering multiple stock lengths. Some designs include a plastic sleeve to prevent concrete ingress around the thread, facilitating easier removal. The choice among these variations influences application speed, safety margins, and long‑term durability, so engineers weigh thread pitch, flange rigidity, and coating type when selecting the ideal hall anchor for each project.

Quality Assurance and Certifications

Every batch of hall anchors passes rigorous quality control: thread gauge inspections ensure tolerance compliance within ±0.1 mm, while tensile and torque tests validate mechanical performance. Third‑party laboratories often verify pull‑out resistance under EN 14399‑1 or ASTM F1554 standards, issuing Material Test Certificates (MTC) that detail chemical composition and mechanical properties. Additionally, ISO 9001 certification confirms that manufacturers maintain a controlled production process, from raw‑material procurement through final packaging. With traceable heat numbers stamped on each flange, contractors can cross‑reference every anchor to its test reports, ensuring on‑site accountability and adherence to contractual specifications.

Why Choose H&F for Your Hall Anchors

When procuring hall anchors through H&F, buyers benefit from free sample provision, allowing performance trials before committing to full orders. Our one‑to‑one customer service connects clients directly with seasoned product specialists, ensuring prompt answers to technical queries and tailored recommendations. Door‑to‑door delivery service simplifies logistics, reducing lead times and on‑site delays. Although we operate as a trading company, we collaborate closely with certified manufacturers to confirm that every hall anchor meets your project’s precise requirements. With transparent pricing, flexible order quantities, and ongoing after‑sales support, H&F stands ready to streamline your formwork anchoring solutions.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

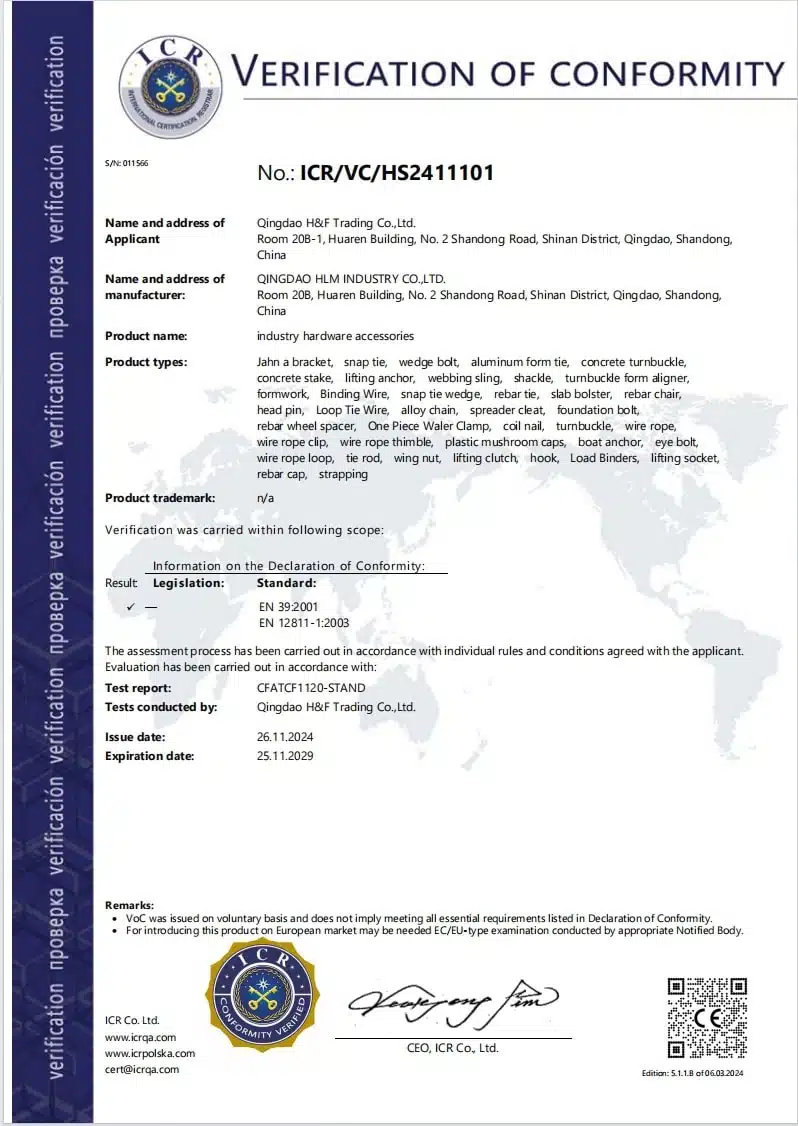

4. Certified Excellence: CE and More for Reliable Partnerships

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Related products

-

Grapnel Anchor

$0.01 -

Folding Grapnel Anchor

$0.01 -

Danforth Anchor

$0.01 -

Bruce Claw Anchor

$0.01