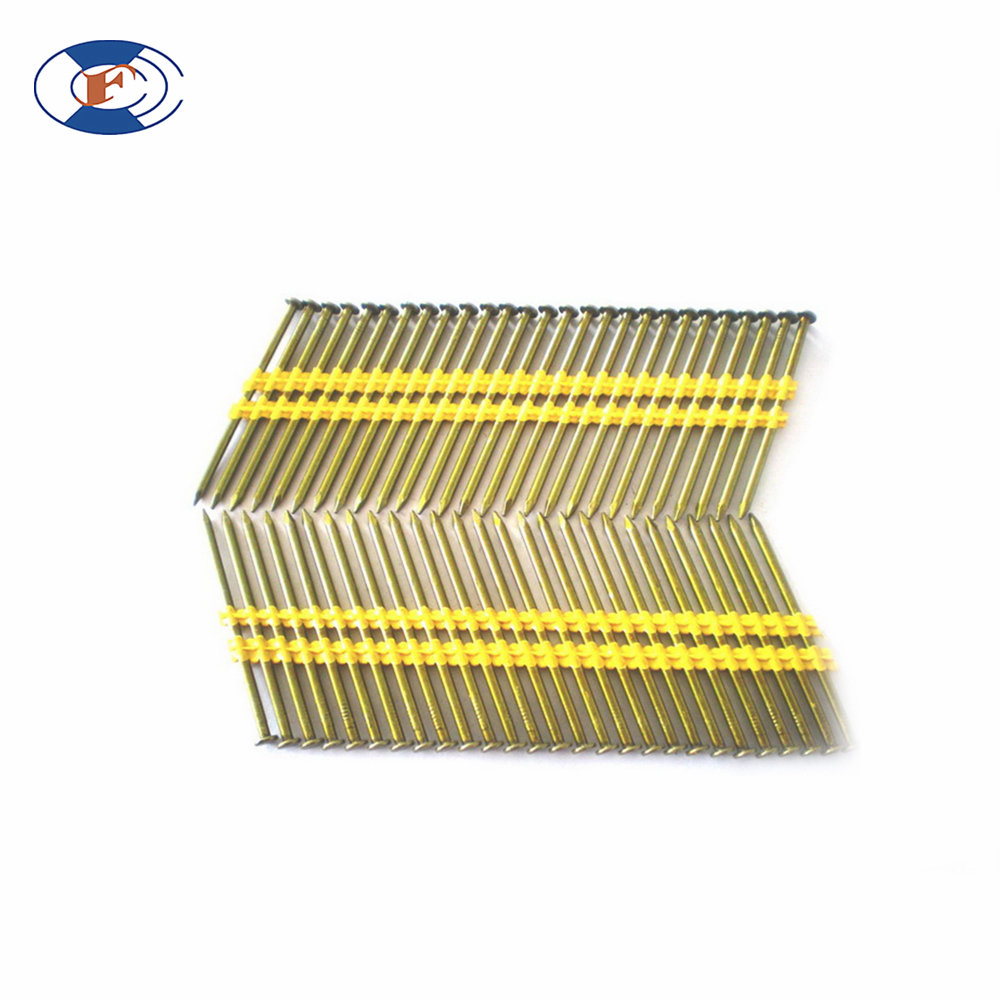

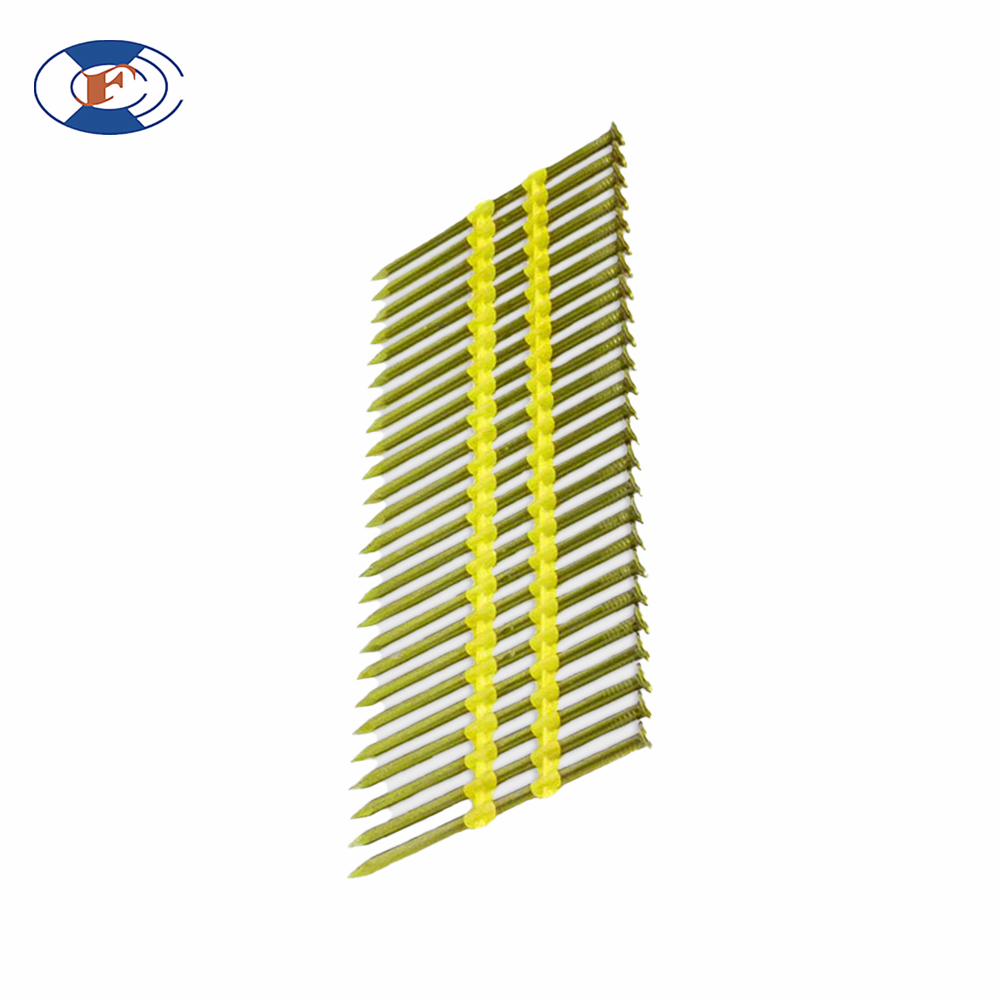

Plastic Strip Nail

Plastic strip nails provide a reliable and convenient fastening solution for a wide range of applications. Their strip configuration, compatibility with nail guns, and versatility make them popular among professionals in the construction and woodworking industries. Additionally, their non-metallic composition and reduced risk of damage to materials make them suitable for specialized applications where metal nails may not be ideal.

- Material: Plastic strip nails are typically made from high-quality, durable plastic materials such as polyethylene or polycarbonate. These materials offer several advantages, including resistance to rust, corrosion, and chemicals. Plastic strip nails are particularly suitable for applications where metal nails may cause staining or react with certain materials.

- Strip Configuration: Unlike individual bulk nails or coil nails, plastic strip nails are connected together in a strip or band formation. This strip configuration allows for easy loading into nail guns and facilitates rapid and continuous firing, reducing downtime for reloading. The nails are spaced evenly on the strip and held together by a flexible plastic strip or adhesive.

- Point and Shank: Plastic strip nails typically have a sharp diamond or chisel point for precise insertion into various materials. The shank (body) of the nail is usually smooth or lightly textured to provide sufficient grip and holding power.

- Sizes and Applications: Plastic strip nails are available in various lengths, diameters, and gauges to accommodate different applications. They are commonly used in construction for framing, sheathing, decking, siding, and general carpentry work. Plastic strip nails are also suitable for applications where non-metal fasteners are required, such as in electrical or plumbing installations.

- Versatility: Plastic strip nails can be used with most pneumatic or cordless nail guns that are compatible with strip nails. These nail guns are designed to efficiently drive the nails into the material, making them ideal for high-volume projects and reducing manual effort.

- Reduced Splitting and Damage: The plastic material used in strip nails offers some advantages over metal nails, particularly in delicate or brittle materials. Plastic strip nails are less likely to cause splitting, cracking, or damage to the material being fastened, making them a preferred choice for applications where preserving the integrity of the workpiece is crucial.

- Environmentally Friendly: Plastic strip nails are often considered more environmentally friendly compared to metal nails. Plastic is recyclable and can be reused or repurposed, offering a sustainable alternative to traditional metal fasteners.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

4. Certified Excellence: CE and More for Reliable Partnerships

Related products

-

Swivel Hook

$1.00 -

Load Binder

$1.00 -

G215 Galvanized Shackle

$1.00