Steel Wire Rope Steel Cable

Our wire ropes are crafted from high-quality materials, including galvanized steel, stainless steel, and carbon steel, to meet diverse operational needs. Galvanized steel provides strong corrosion resistance, ideal for outdoor and marine environments. Stainless steel offers even greater protection against corrosion in harsher conditions, while carbon steel is valued for its high tensile strength, making it perfect for heavy-duty applications.

We offer wire ropes in common configurations like 6×19, 6×36, and 7×19, which balance flexibility and strength. Typical diameters range from 1/8 inch (3.2mm) to 3/8 inch (9.5mm), including popular sizes such as 3/16 inch (4.8mm) and 1/4 inch (6.4mm). These sizes are suitable for a wide range of applications, from light lifting to heavy industrial use. Custom lengths and coatings are also available to meet specific project requirements, ensuring you receive the most suitable wire rope for your needs.

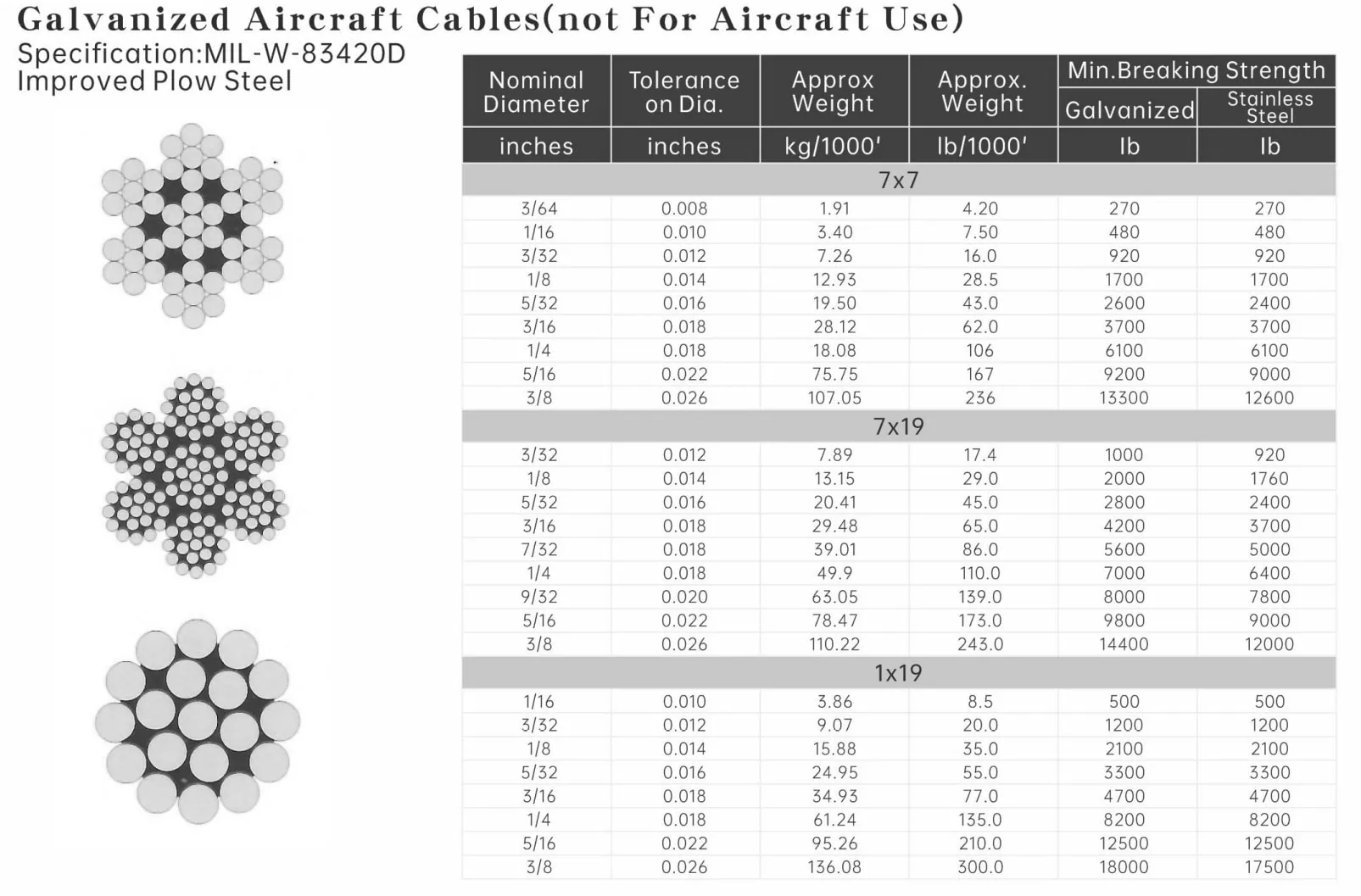

Specification: MIL-W-83420D – Improved Plow Steel

The MIL-W-83420D specification defines wire ropes made from improved plow steel, known for its superior strength and durability. Here, we’ll look at the available sizes and constructions for these wire ropes.

7×7 wire rope

The 7×7 wire rope consists of seven strands, each made up of seven wires. This construction offers a balance of flexibility and strength, making it suitable for applications where moderate bending is required.

Available Sizes: 3/64, 1/16, 3/32, 1/8, 5/32, 3/16, 1/4, 5/16, 3/8 inches.

Focus Sizes:

- 3/16 inches: This size is ideal for light to medium-duty applications such as guy wires and control cables.

- 1/4 inches: Used in slightly more robust applications including rigging and hoisting.

- 3/8 inches: Suitable for heavy-duty tasks like lifting and supporting structures.

7×19 wire rope

The 7×19 wire rope consists of seven strands, each with nineteen wires. This configuration provides greater flexibility compared to the 7×7 construction and is commonly used in dynamic applications.

Available Sizes: 3/32, 1/8, 5/32, 3/16, 7/32, 1/4, 9/32, 5/16, 3/8 inches.

Focus Sizes:

- 1/8 inches: Often used for small pulleys, control cables, and winches.

- 3/16 inches: Suitable for more demanding tasks like heavy-duty garage door cables.

- 1/4 inches: Common in larger-scale marine and industrial applications.

- 3/8 inches: Optimal for major lifting and load-bearing applications.

1×19 wire rope

The 1×19 wire rope comprises a single strand made up of nineteen wires. It is stiffer than both the 7×7 and 7×19 constructions, providing high strength and low stretch, making it perfect for static applications.

Available Sizes: 1/16, 3/32, 1/8, 5/32, 3/16, 1/4, 5/16, 3/8 inches.

Focus Sizes:

- 1/8 inches: Used for architectural purposes such as railings and balustrades.

- 1/4 inches: Common in mast stays and other rigging applications.

- 3/8 inches: Suitable for high-load, low-flex applications like bridge cables.

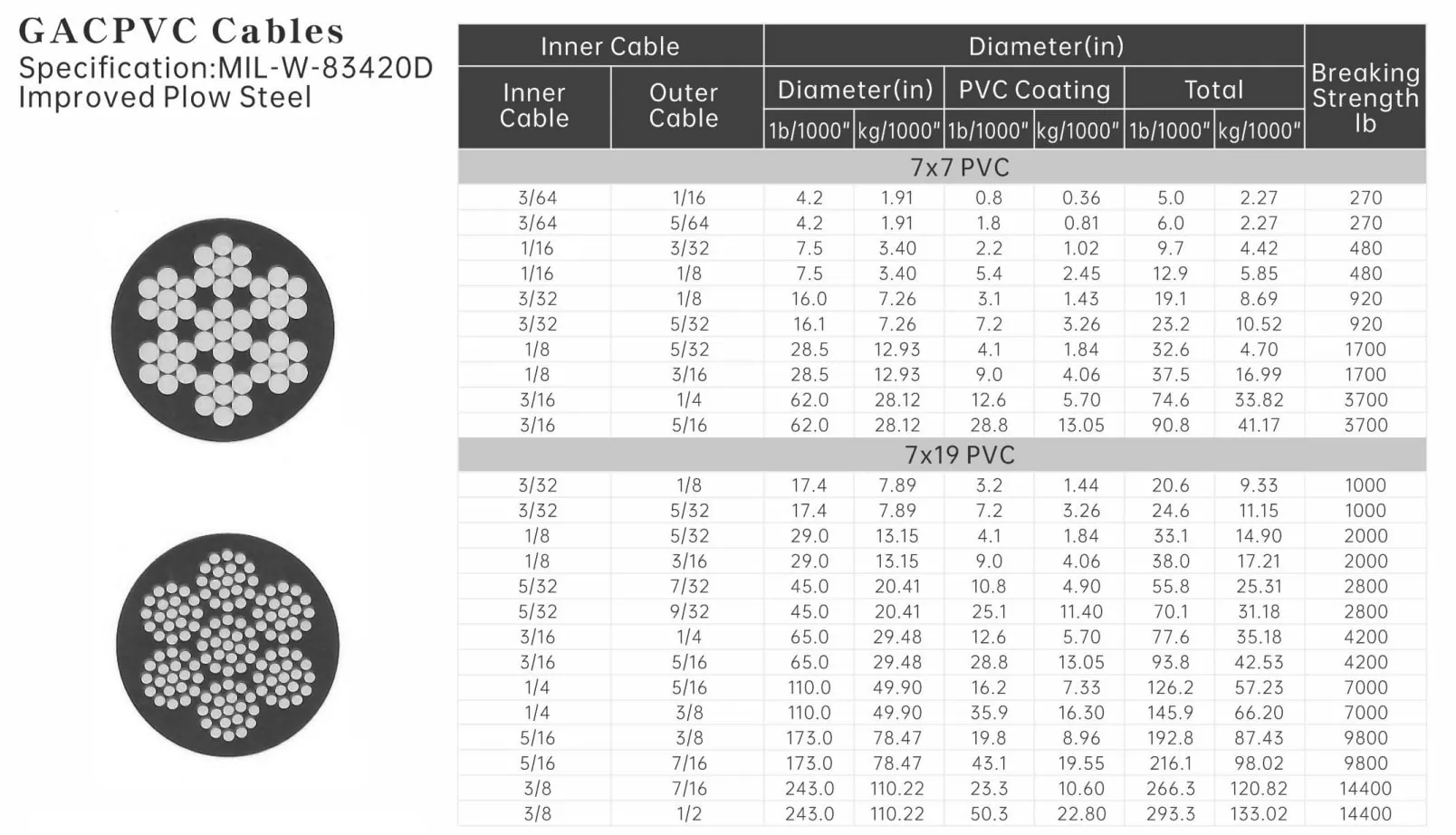

Specification: MIL-W-83420D – PVC Coated Improved Plow Steel

PVC coating adds an extra layer of protection to wire ropes, making them resistant to environmental factors such as moisture and chemicals.

7×7 PVC Coated Wire Rope

The 7×7 construction with PVC coating enhances durability while maintaining flexibility.

Available Sizes: 3/64, 1/16, 3/32, 1/8, 3/16 inches.

7×19 PVC Coated Wire Rope

The 7×19 construction with PVC coating offers superior flexibility along with enhanced protection.

Available Sizes: 3/32, 1/8, 5/32, 3/16, 1/4, 5/16, 3/8 inches.

Focus Sizes:

- 1/8 inches: Ideal for outdoor applications like fencing and landscape cables.

- 3/16 inches: Suitable for marine environments where corrosion resistance is crucial.

- 1/4 inches: Often used in safety and security applications.

- 3/8 inches: Used in heavy-duty applications requiring robust performance in harsh conditions.

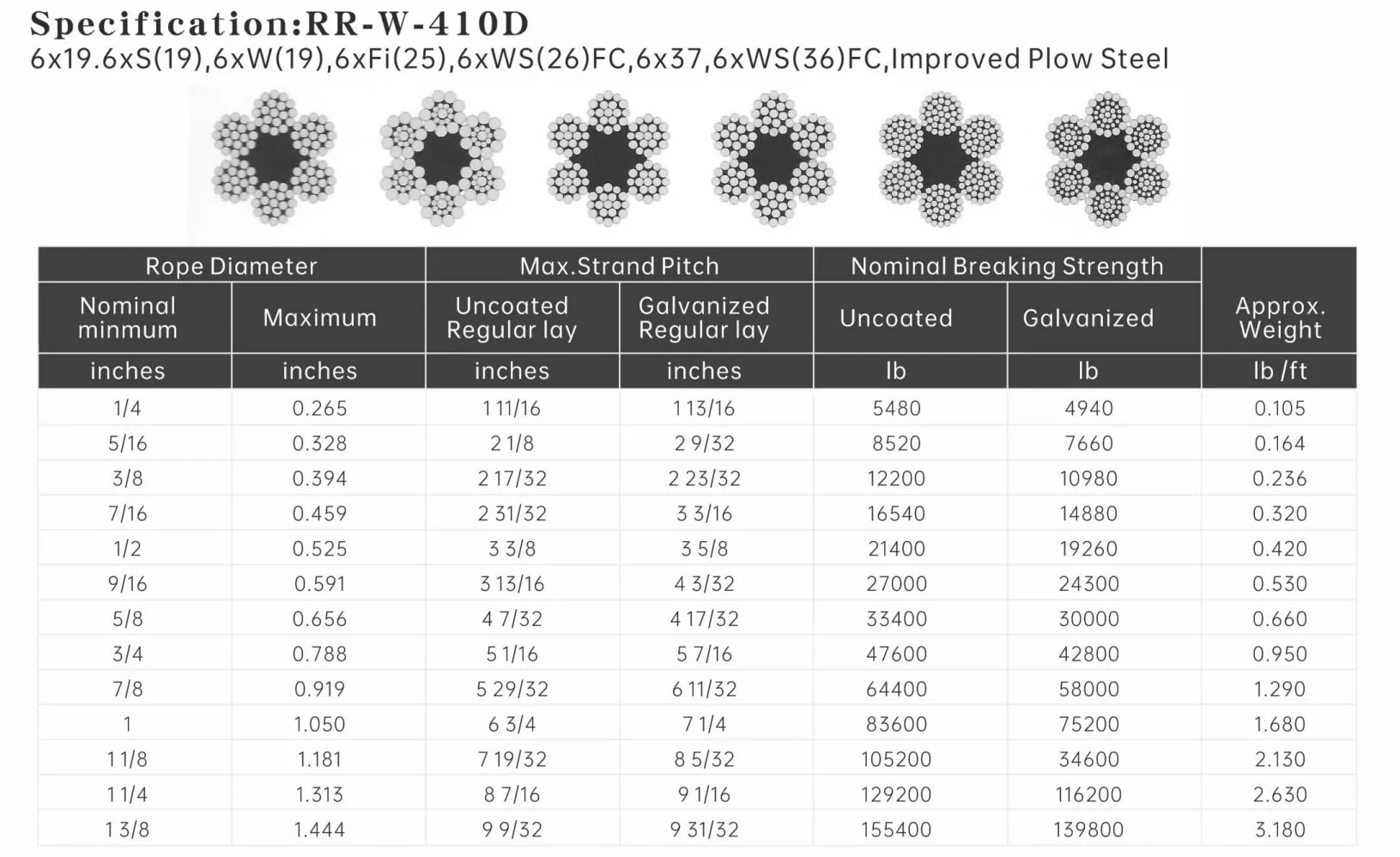

Specification: RR-W-410D – Improved Plow Steel

The RR-W-410D specification pertains to wire ropes made from improved plow steel, with various constructions available for different uses.

Wire Rope Types

- 6×19, 6xS(19), 6xW(19), 6xFi(25), 6xWS(26)FC, 6×37, 6xWS(36)FC

Available Sizes: 1/4, 5/16, 3/8, 7/16, 1/2, 9/16, 5/8, 3/4, 7/8, 1, 1 1/4, 1 3/8 inches.

Focus Sizes:

- 1/4 inches: Utilized in hoisting, towing, and load-bearing applications.

- 3/8 inches: Employed in construction and structural support systems.

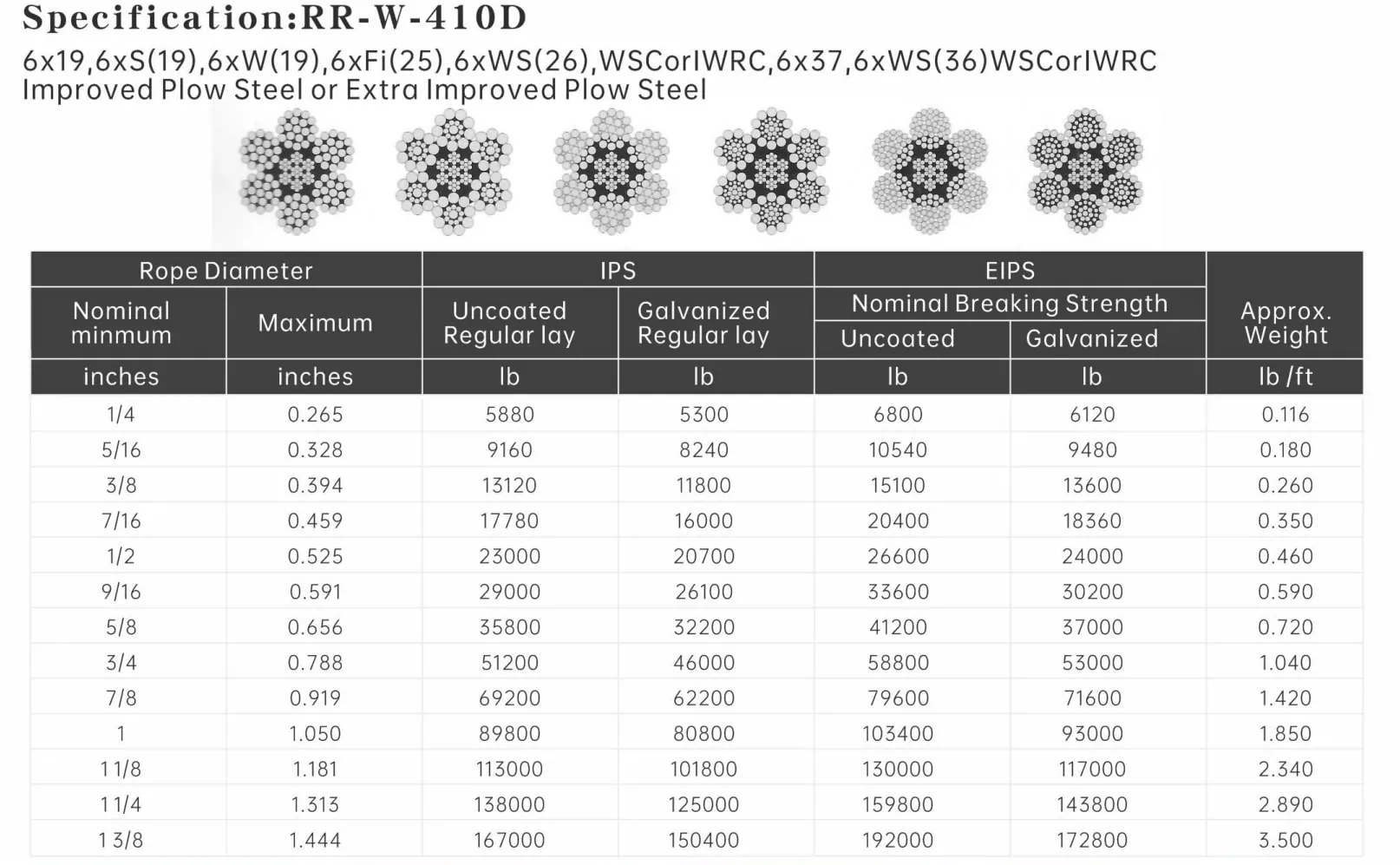

Specification: RR-W-410D – Improved and Extra Improved Plow Steel

This specification also covers wire ropes made from both improved and extra improved plow steel, providing additional strength and durability.

Wire Rope Types

- 6×19, 6xS(19), 6xW(19), 6xFi(25), 6xWS(26), WSC or IWRC, 6×37, 6xWS(36)WSC or IWRC

Available Sizes: 1/4, 5/16, 3/8, 7/16, 1/2, 9/16, 5/8, 3/4, 7/8, 1, 1 1/4, 1 3/8 inches.

Focus Sizes:

- 1/4 inches: Used in industrial lifting and rigging.

- 3/8 inches: Commonly used in construction, mining, and marine applications.

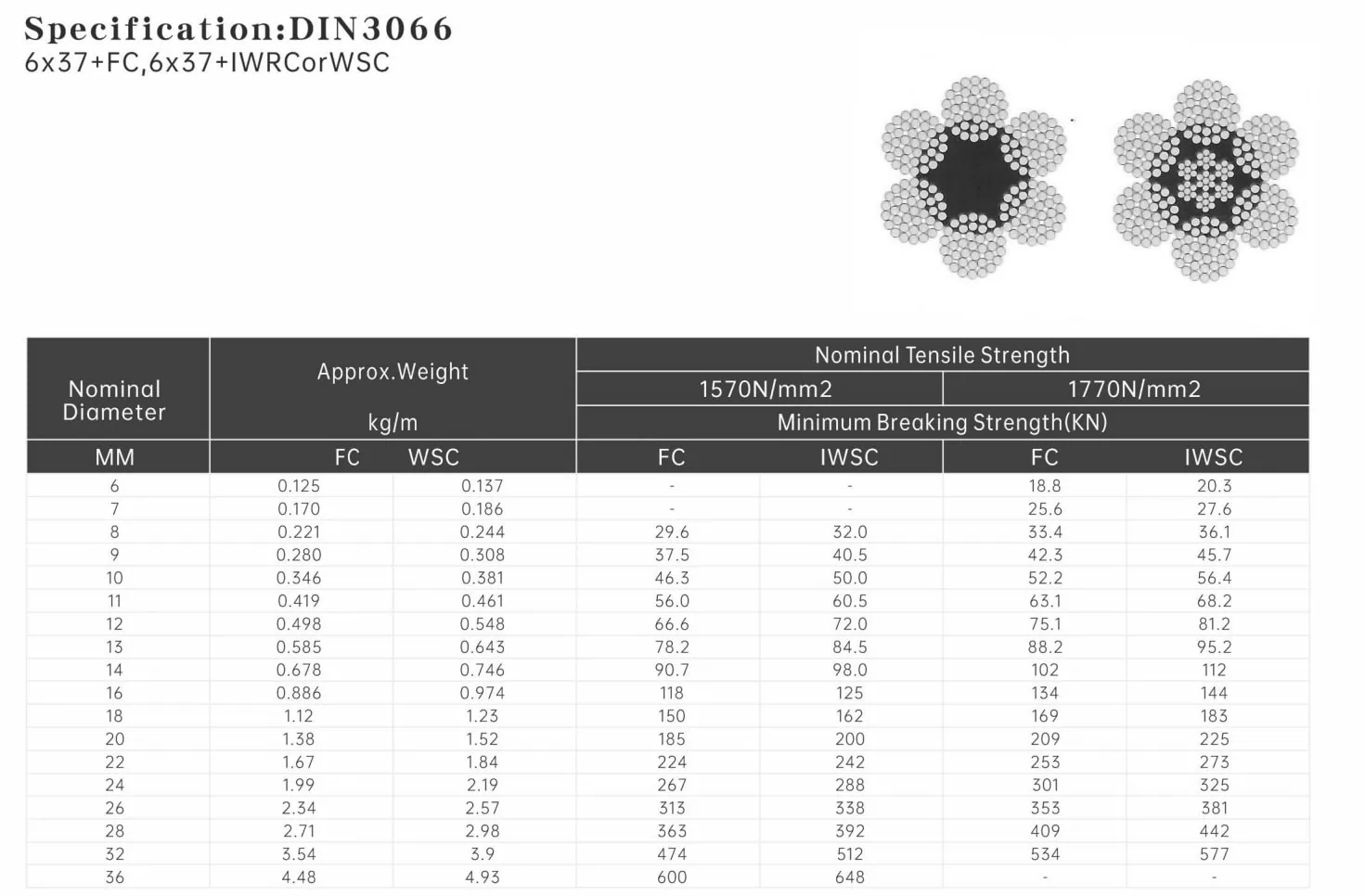

Specification: DIN3066

The DIN3066 specification defines wire ropes with various core options and construction types, made to high German standards.

Wire Rope Types

- 6×37+FC, 6×37+IWRC or WSC

Available Sizes: 6, 7, 8, 9, 10, 11, 12, 13, 14, 16, 18, 20, 22, 24, 26, 28, 32, 36 mm.

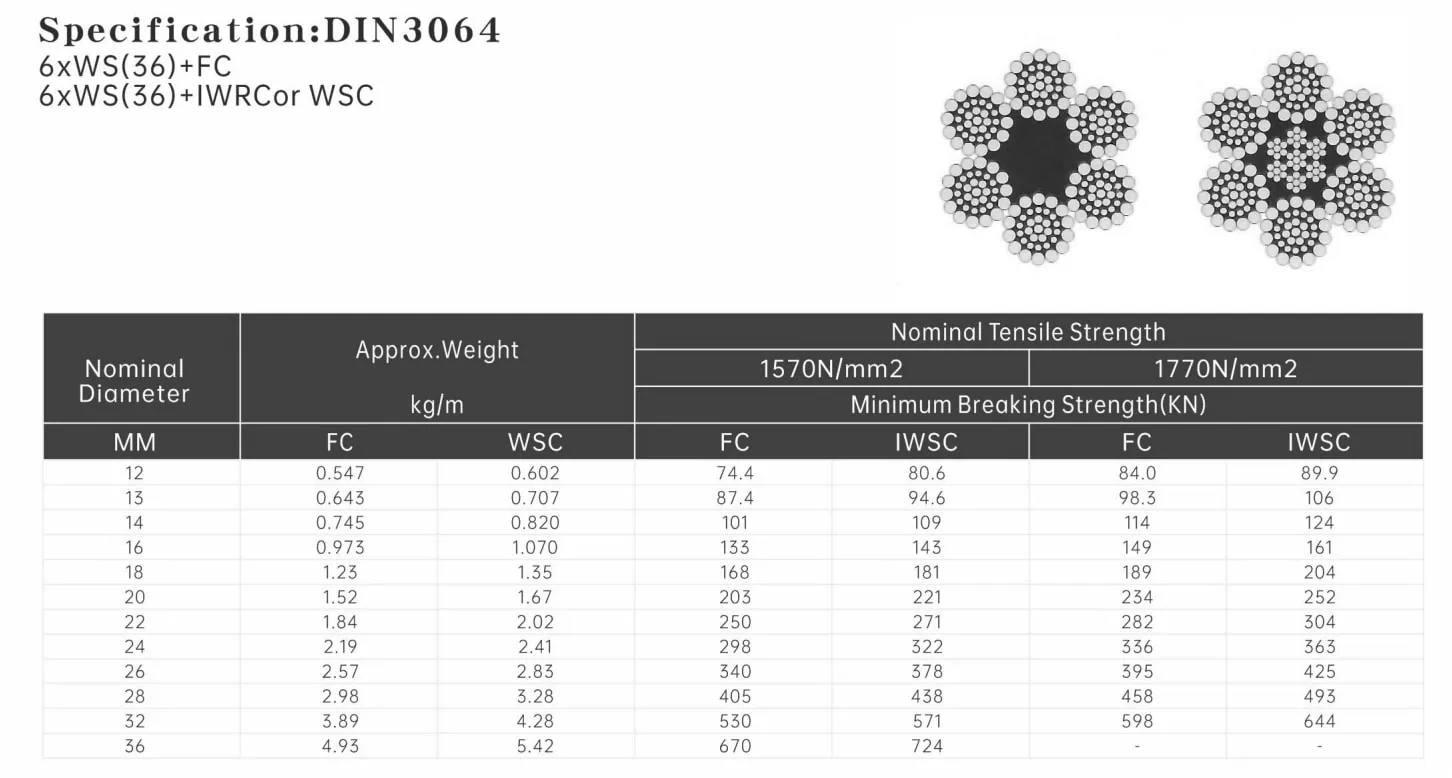

Specification: DIN3064

DIN3064 wire ropes are designed for specific high-strength applications with various core options.

Wire Rope Types

- 6xWS(36)+FC, 6xWS(36)+IWRC or WSC

Available Sizes: 12, 13, 14, 16, 18, 20, 22, 24, 26, 28, 32, 36 mm.

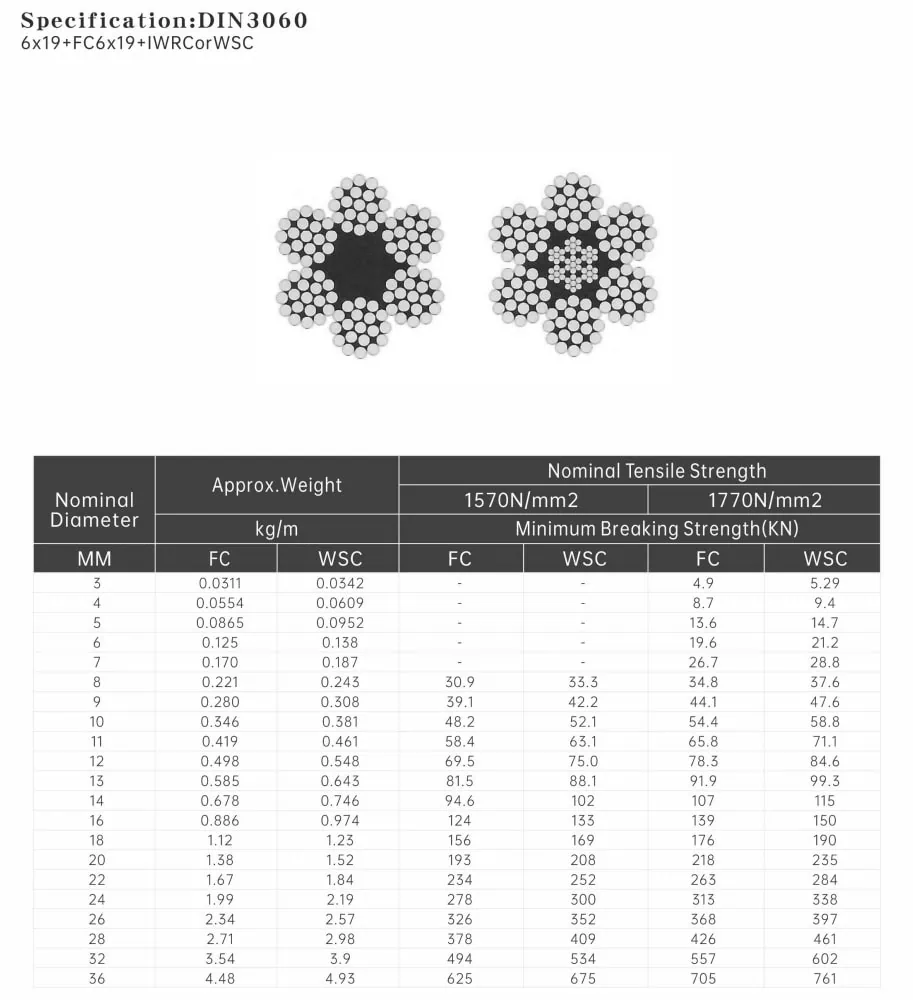

Specification: DIN3060

DIN3060 wire ropes provide a balance of flexibility and strength, with various core options.

Wire Rope Types

- 6×19+FC, 6×19+IWRC or WSC

Available Sizes: 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 16, 18, 20, 22, 24, 26, 28, 32, 36 mm.

Why Choose Our Steel Wire Rope?

Manufacturer and Factory Direct: As a leading manufacturer, we have our own cooperative factory, ensuring superior quality control and competitive pricing.

Supplier and Vendor: With decades of experience, we have established ourselves as a trusted supplier and vendor in the industry, providing you with top-notch products.

In-Stock and Ready to Ship: Our extensive inventory allows us to fulfill your orders promptly, ensuring that the steel wire ropes you need are readily available.

Competitive Wholesale Prices: We offer our steel wire ropes at wholesale prices, making us the preferred choice for businesses seeking cost-effective solutions.

QC Inspection Report: Quality is our priority. Each steel wire rope undergoes rigorous quality control, and we provide a comprehensive QC Inspection Report for your peace of mind.

Customization Services: We understand that your projects may have unique requirements. Our team is here to customize the steel wire rope to meet your specific needs.

Free Samples: To ensure you make an informed decision, we offer free samples of our steel wire rope, allowing you to assess its performance firsthand.

One-on-One Service: Our dedicated team is committed to providing personalized one-on-one service, guiding you through the entire purchasing process.

Our Services:

Wholesaler and Distributor: We serve as a wholesaler and distributor, catering to your bulk requirements of steel wire ropes and other rigging hardware.

China-based Manufacturing: Our factory in China ensures access to high-quality products at competitive prices, backed by China’s manufacturing excellence.

Global Sourcing Capabilities: As experts in sourcing, we can assist you in finding the best solutions for your industrial needs.

Here are some common types of wire rope rigging hardware:

Wire Rope Clips

Wire rope clips, also known as cable clamps or u-bolt clamps, are used to create an eye or loop in a wire rope by securing the loose end to the standing part of the rope. They consist of a u-shaped bolt, a saddle, and two nuts that are tightened to secure the rope in place.

Our Duplex Wire Rope Clips offer exceptional reliability and secure fastening solutions for various applications, making them an ideal choice for your diverse needs.

Shackles

Shackles are U-shaped metal connectors with a pin or screw-type closure. They are used to join wire ropes, slings, or other lifting components. Shackles come in various types, including anchor shackles, chain shackles, and bow shackles, each suited for different applications and load capacities.

Turnbuckles

Turnbuckles, also called bottle screws or rigging screws, are adjustable tensioning devices used to tighten or loosen wire ropes. They consist of two threaded eye bolts or hooks connected by a body that can be rotated to increase or decrease the tension in the wire rope.

Swivels

Swivels are rotating connectors that allow wire ropes to rotate freely without twisting or kinking. They are commonly used in lifting operations and applications where the load needs to rotate or change direction.

Thimbles

Thimbles are metal sleeves inserted into the eyes or loops of wire ropes to prevent wear and deformation caused by friction and bending. They help maintain the rope’s shape and protect it from abrasion.

Hooks

Hooks are curved or bent metal devices used to connect wire ropes to loads or other rigging components. They come in various configurations, such as clevis hooks, grab hooks, and eye hooks, and are designed to securely hold and suspend loads.

Links and Rings

Links and rings are circular connectors made of metal. They are used to join multiple wire ropes or connect wire ropes to other rigging hardware. They provide a secure and reliable connection point in rigging assemblies.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

4. Certified Excellence: CE and More for Reliable Partnerships

Related products

-

Bruce Claw Anchor

$1.00 -

7×7 Wire Rope

$1.00