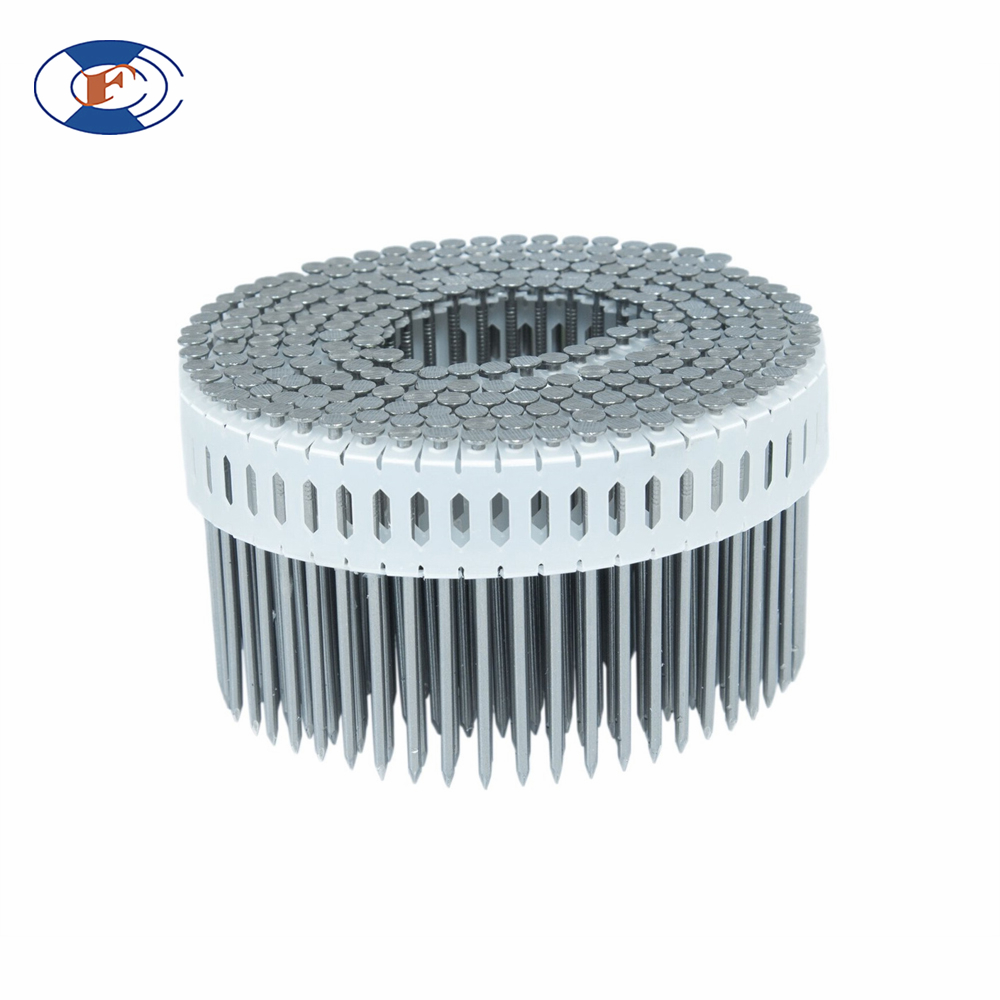

There are many ways to describe a coil nail for concrete, but to simply understand what they are is by looking at them, You will see they are a joint together or hand in hand collection of nails arranged in a circular shape which is held together by a piece of iron or metal which is then loaded on a Nail Gun.

Coil nails are popular among all contractors traders and suppliers and they are often used on floors and roofs as they simply hold the structure together. As we know nod nails and coil head nails go hand in hand, you could have a pile of them lying around your house without you even knowing it.

As a professional coil nail supplier. Many people don’t know the specific uses of coil nails. What are coil nails? After reading this article you may have the answer.

There are many types of coil nail used in industrial environments.

1: According to the material, it can be divided into galvanized carbon steel or stainless steel.

2: The most common types of finish on nail, they are classified as bright, electro-galvanized and hot-dip galvanized.

3: According to the type of nail handle, it can be divided into Smooth Shank, Ring Shank, Screw Shank.

4: According to its type of finishing is divided into: plastic coil nails, wire coil nails.

Read on and I will explain the difference between them!

The Differences Between Galvanized Coil Nails And Stainless Steel Colil Nail

Galvanized Coil Nails

Galvanized coil nails.They coated with a layer of zinc to resist corrosion. The galvanizing process also distinguishes between hot-dip galvanizing and electro-galvanizing. The advantage of galvanized nails is that they are corrosion resistant and ductile, making them easier to work with. The biggest advantage is the low price. However, it does not resist salt water.

Stainless Steel Coil Nails

Stainless steel nails.They are made by adding chromium to fresh water. It is extremely strong and corrosion resistant, even to salt water. And it is stronger and more durable than galvanized ding. But it does cost several times as much as galvanized nails.

The Types Of Finish On Nail

Bright

Nails do not have any coating and are susceptible to corrosion, so they should not be used outdoors or in wet environments. It is mainly used in the manufacture of pallets and boxes where corrosion problems do not occur.

Advantages: inexpensive. Disadvantages: not resistant to corrosion

Electro-Galvanized

Nails are immersed in an electrolyte solution containing zinc ions. An electric current is passed through the solution, causing the zinc ions to bind to the metal surface and form a thin zinc layer. Galvanized coatings are typically used for indoor applications or environments with low corrosion exposure

Advantages: corrosion resistant and moderately priced. Disadvantages: Less durable.

Hot-Dip Galvanizing

The nail is immersed in a molten zinc bath at a temperature of approximately 450-480 degrees Celsius (842-896 degrees Fahrenheit). The zinc reacts with the metal surface, forming a metallurgical bond and a thicker, stronger zinc coating.

This results in greater resistance when used in wet environments. Hot-dip galvanized coatings are widely used in outdoor applications and in harsh environments where corrosion resistance is critical.

Benefits: Good corrosion resistance and durability. Disadvantages: Expensive.

Different Type of Nail Shank

Smooth Shank

Smooth shank nails are the most common type. They are commonly used for framing and general construction applications. They provide adequate support for most everyday use.

They are easy to produce and cost less. However, smooth shank nails lack the best holding power and cannot be used for jobs that require a lot of tensile strength, such as roofing.

Applications: Framing, Siding, Trim and Finishing, General Woodworking

Ring Shank

Ring shank nails have a better grip than bare shank nails with ring threads. When driven, the ring threads provide a “locking” effect with the wood material, and the wood fills the cracks in the ring, which provides friction to help prevent the nail from exiting over time, and does not damage the wood. These nails are suitable for softer woods.They are a preferred nail roofing product.

Applications: Siding, Roof Decking, Asphalt Shingles, Underlayment, Subfloors

Screw Shank

A screw shank nail is a combination of a nail and a screw. Screw shank nails are typically used in hardwoods to prevent the wood from splitting when the fastener is driven.

When the nail is driven in, a tight groove is formed using the threads of the screw. Making it less likely that the fastener will exit. This type of nail requires a more responsible manufacturing process, so the price is more costly than smooth shank and ring shank nails.

Applications: Decking, Flooring, Pallet Assembly, Siding, Fencing, Framing, Sheathing

Different Type of Coil Nail Collation

Plastic-Collated Coil Nails

Plastic Coil nails do not necessarily have to be attached with metal wire, but can also be inserted into plastic strips, called plastic rows of coil nails or intermediate coil nails.

Since these nails easily come off the strip when nailing, the direction of nailing can remain the same. plastic band is generally used for 15 degree coil nails

plastic band is a more expensive alternative to plastic strip, but it eliminates cluttered job sites and plastic debris stuck under the nail head. The plastic strip outlet is a one-piece coil nail gun for easy cleanup.

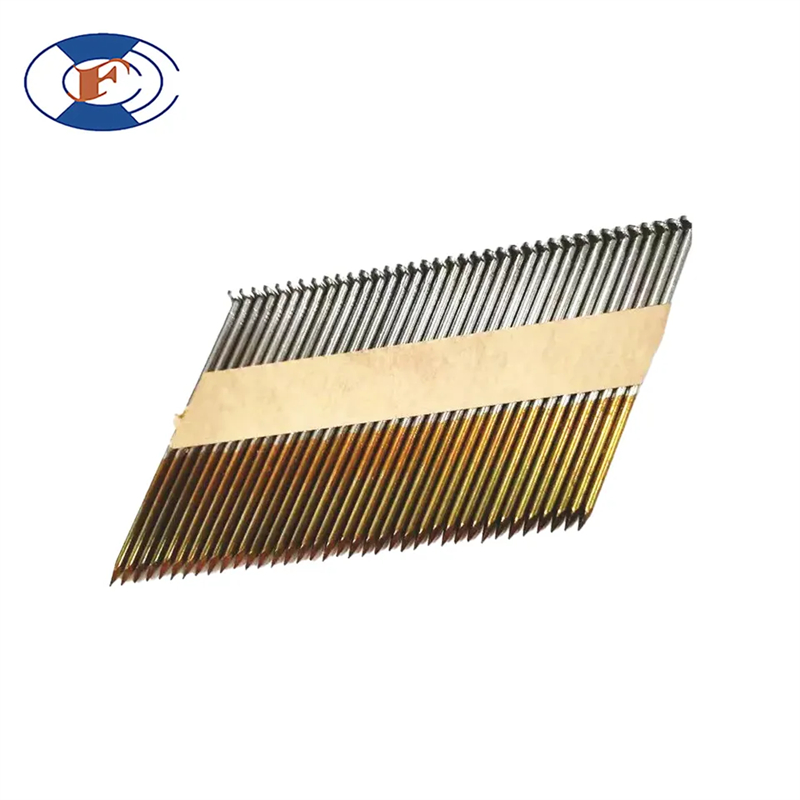

Wire-collated Coil Nails

Wire-collated Coil Nails is generally used for 28 degree framing nails and 15 degree coil nails.

Wire-collated Coil Nails use a thin metal wire to hold the fastener in place. They are not as susceptible to water or cold weather as paper or plastic nails, however, they can shoot sharp pieces of metal around the job site and it is easy to snag the wire under the head, exposing the nail.

Other Nail

Paper Tape Collation

Paper strip nail.Paper tape is typically used for 30 to 34 degree framing nails, using a strip of paper with glue to hold the nail together. The paper is driven into the wood along with the nail, with the benefit of easy cleanup.

Paper strips also reduce the risk of material getting stuck under the nail head and leaving the top of the fastener exposed. The disadvantage is that the paper can become wet in rainy or wet conditions, which can cause the paper to separate from the nail.

Plastic Strip Collation

Plastic strip nail.Plastic strip are generally used for 20-22 degree and 15 degree framing nails, which are less costly because of their manufacture. They are held together by a strip of plastic, which separates when used.

They leave a mess of plastic around the work site, which is difficult to clean. When the weather is cold, the plastic strips become very fragile. They also leave pieces of plastic under the head, causing nails to be exposed.

Conclusion about Coil Nails

When it comes to choosing a coil nail, a zinc plated coil nail is one of the most economical and practical choices. When you are installing a roof,you need to use roofing coil nails.Ring shank is the best choice.

smooth shank does not have the required tension for fixing and screw shank is too expensive and difficult to nail into hardwood.

FAQ about Coil Nails

What Are Coil Nails Used For?

Coil nails are commonly used in construction projects for applications such as framing, decking, roofing, siding, and other woodworking projects.

What Is The Advantage Of Using Coil Nails?

One of the main advantages of coil nails is their high capacity. The coil shape allows for a larger quantity of nails to be held in a single coil, reducing the need for frequent reloading, thereby increasing productivity.

Are Coil Nails Suitable For Outdoor Use?

Yes, coil nails can be used for outdoor projects. However, it is important to consider the coating and material of the nails to ensure they have proper corrosion resistance for outdoor environments.

Can Coil Nails Be Used With Pressure-Treated Lumber?

Yes, coil nails can be used with pressure-treated lumber. It is recommended to use stainless steel or hot-dipped galvanized coil nails for better resistance against the chemicals in the pressure-treated wood.

Can Coil Nails Be Used For Hardwood Installations?

Yes, coil nails can be used for hardwood installations. It is advisable to choose nails with a smooth shank to minimize splitting and ensure a secure hold.

What Is The Typical Length And Diameter Of Coil Nails?

Coil nails come in various lengths and diameters. Common lengths range from 1.5 inches to 3 inches, while diameters typically range from 0.099 inches to 0.131 inches.

How Do I Choose The Right Coating For Coil Nails?

The choice of coating depends on the application and environment. Galvanized coatings are suitable for general construction purposes, while stainless steel is recommended for outdoor projects requiring high corrosion resistance.

Are Coil Nails Compatible With All Nail Guns?

Coil nails are designed to be used with specific coil nail guns. It is important to check the compatibility of the nail gun and the nail specifications before making a purchase.

What is the holding power of coil nails?

The holding power of coil nails can vary depending on the nail’s diameter, length, and material. It is recommended to refer to the manufacturer’s specifications for information on the specific nail’s holding power.

Can You Hang Drywall With a Nail Gun?

Never with an ordinary nail gun – not one that shoots framing nails, not one that shoots sheathing nails, nor a brad gunned even then, it’s hard to get the depth just right – it’s easy for them to be too proud (which you can fix with a hammer) or to go too deep and tear the paper and if you do that, you need to place another nail close by.

Drywall is really predictable stuff – the whole room (give or take the ceiling) is done in 1/2″ or 5/8″ or, rarely, double 5/8″ but the stud behind the drywall can vary a lot in hardness from the common, widely-spaced growth rings of most framing lumber to the occasional 2×4 from an older tree and on to much older denser wood when remodelling old homes (I counted 90 rings in one inch in my 1910 Seattle house).

How Do You Make a Nail Magnetic With a Coil Wire, Nail And a Duracell D Battery?

It’s as simple as wrapping that coil around the nail and then connecting both ends to the battery.

· One to the positive end

· The other to the negative end

You now have an electromagnet. And in many cases, the nail will remain slightly magnetized after you remove the battery.