Wall Ties for Aluminum Forms

Creating a strong, secure concrete foundation is crucial for any construction project. Wall Ties for Aluminum Forms play a vital role in achieving this goal by ensuring proper formwork spacing and withstanding concrete pressure during the pouring process. This guide dives deep into Wall Ties for Aluminum Forms, exploring their types, functionalities, and how they work with essential companion products like Pins and Wedges.

Ensure Strong Foundations: Understanding Wall Ties for Aluminum Forms

Building a solid concrete foundation is essential for any construction endeavor. Wall Ties for Aluminum Forms play a crucial role in this process by maintaining formwork spacing and enduring concrete pressure during pouring. This guide delves into Wall Ties for Aluminum Forms, covering their types, functions, and how they work with key companion products like Pins and Wedges.

Understanding Wall Tie Functionality

Wall Ties serve as the backbone of aluminum formwork systems. These metal rods are strategically positioned within the formwork to keep a consistent gap between inner and outer aluminum panels, determining the final thickness of the concrete wall. They’re built to withstand the outward pressure from poured concrete, preventing formwork from bending or collapsing.

Full Wall Ties vs. Nominal Wall Ties: Choosing the Right Fit

Wall Ties are divided into two main categories: Full Wall Ties and Nominal Wall Ties. The choice depends on your project’s needs:

Full Wall Ties: These span the entire width of the concrete wall, ideal for standard wall constructions where the desired concrete thickness matches the formwork panel’s width. They offer maximum stability and are typically preferred for most projects.

Nominal Wall Ties: Shorter than the full width of the formwork, Nominal Wall Ties are used when the desired concrete thickness is less than the panel’s width. They provide necessary spacing for thinner concrete sections while accommodating insulation or other exterior materials.

Material Matters: Durability and Strength

Wall Ties are usually made from high-strength steel to handle the weight and pressure of wet concrete. Some may be crafted from alternative materials like galvanized steel or epoxy-coated steel for added benefits such as corrosion resistance in moist or salty environments.

| Item | Wall Size | Weight | Ultimate Load |

|---|---|---|---|

| Full Wall Tie | 6" | 133g | 7,200lbs |

| Full Wall Tie | 8" | 155.1g | 7,200lbs |

| Full Wall Tie | 9" | 170.3g | 7,200lbs |

| Full Wall Tie | 10" | 185.5g | 7,200lbs |

| Full Wall Tie | 12" | 217.8g | 7,200lbs |

| Nominal Wall Tie | 6" | 127g | 7,200lbs |

| Nominal Wall Tie | 8" | 150.6g | 7,200lbs |

| Nominal Wall Tie | 10" | 181g | 7,200lbs |

| Nominal Wall Tie | 12" | 211.3g | 7,200lbs |

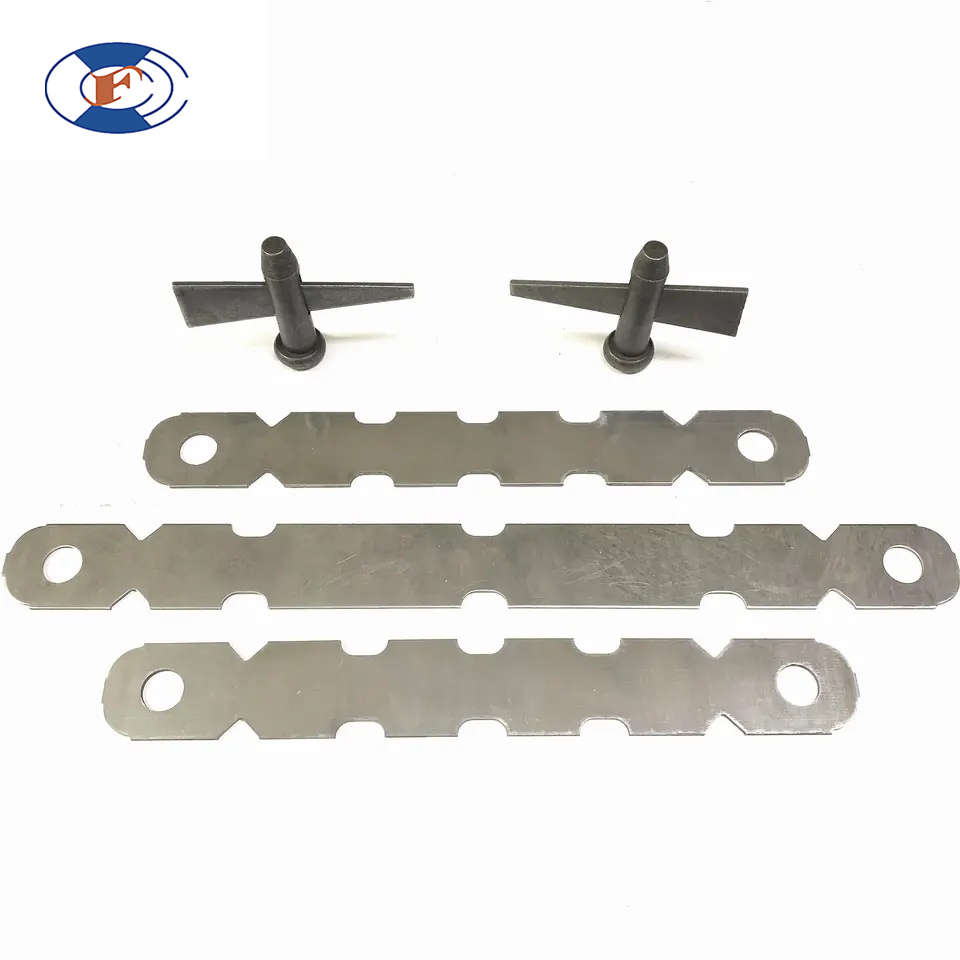

The Vital Companions: Pins and Wedges

Wall Ties work alongside two critical companion products: Pins and Wedges. Here’s how they contribute:

Pins: These slender metal rods slide through designated holes in the Wall Tie, securing it to the aluminum formwork panels.

Wedges: Tapered metal pieces, wedges are placed on the exposed end of the pin and expanded within the Wall Tie hole using a hammer. This ensures a tight and secure connection between the Wall Tie, Pin, and formwork panel.

| Aluminum Forming System Accessories | ||||

|---|---|---|---|---|

| Picture | Item | Size | Material | Feature |

| Flat Head Pin | 71g | Steel #45 | Heat Treatment |

| Round Head Pin | 103g | Steel #45 | Heat Treatment |

| Comobo Pin | 178g | Steel #45 | Heat Treatment |

| Straight Wedge | 49.2g | Steel #45 | Heat Treatment |

| Curved Wedge | 49.4g | Steel #45 | Heat Treatment |

Aluminum Form Tie Tensile Test

The tensile test of aluminum form ties is a crucial process in the construction industry to assess the strength and reliability of form ties used in concrete formwork systems. Form ties are essential components that hold the formwork together and ensure that the concrete structure remains stable during the curing process. Aluminum form ties, in particular, offer advantages such as lightweight, corrosion resistance, and ease of handling.

Additional Considerations

Remember these points when using Wall Tie systems:

Wall Tie Selection: Always use Wall Ties designed for your aluminum formwork system to avoid stability issues.

Loading Capacity: Check the Wall Tie’s load capacity to ensure it can withstand anticipated concrete pressure.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.