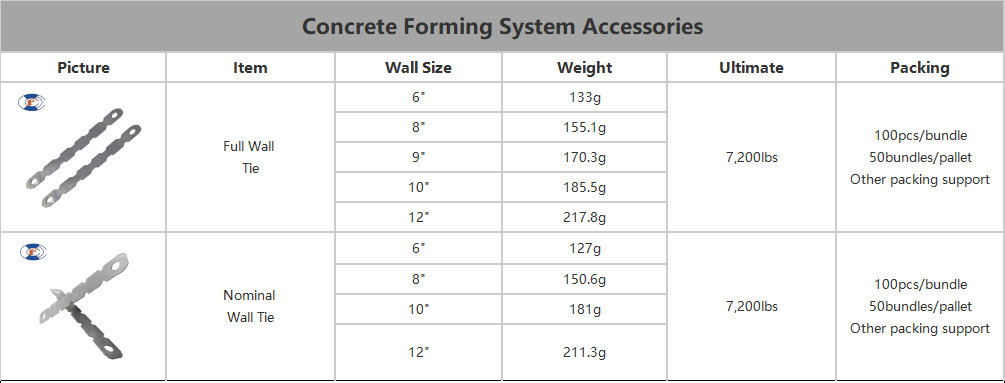

Aluminum Form Tie Full Wall Tie Nominal Tie

Full ties are used to connect opposite sides of the formwork. They extend through the entire thickness of the concrete, creating a continuous connection between the two sides. Full ties are essential for ensuring that the formwork can withstand the pressure of the concrete as it is poured and cured. They are typically made of steel and are designed to be easily removable after the concrete has hardened.

Nominal ties are used to hold the two sides of the formwork together without penetrating the concrete. They are typically made of plastic or other non-metallic materials and are used in situations where the concrete does not need to be completely reinforced. Nominal ties are used for smaller concrete projects, such as walls or sidewalks, where the load on the formwork is relatively low.

Understanding Aluminum Form Ties

Aluminum form ties are essential in concrete forming applications where precision and strength are crucial. H&F builds form ties that won’t let you down in the field, combining rugged durability with practical features that won’t break your budget.

Key Features of Aluminum Form Ties

Strength and Durability

These ties don’t mess around when it comes to strength – they’re built like tanks to keep your concrete structures rock-solid. Weather them, work them, expose them to the elements – they’ll keep performing day after day.

Lightweight and Easy Handling

You might expect all that muscle to come with extra weight, but these ties stay surprisingly light. Your crews can work faster and longer without wearing themselves out.

Types of Aluminum Form Ties

Full Ties

Full ties are your go-to option when you’re dealing with serious formwork that demands unwavering support and performance.

Applications of Full Ties

These workhorses show up on major projects where the formwork needs to handle massive loads without flinching.

Advantages of Full Ties

Count on full ties to resist tension like champions while keeping everything locked in place throughout the curing process.

Nominal Ties

Nominal ties step up when you need a perfect balance between strength and maneuverability.

Uses of Nominal Ties

Perfect for smaller projects or anywhere weight savings matter without sacrificing reliability.

Benefits of Nominal Ties

These ties prove you don’t need excessive bulk to deliver solid performance in the field.

Key Benefits and Quality Assurance

Corrosion Resistance and Efficiency

Throw whatever mother nature’s got at these ties – their natural corrosion resistance means they’ll keep performing in harsh conditions. The lightweight design isn’t just about convenience – it translates to real efficiency gains without compromising structural integrity.

Quality Control Measures

At H&F, we’re obsessive about quality. Each tie faces a gauntlet of testing to ensure it’ll perform exactly as promised when you need it most.

Customer Service Excellence

We know construction inside and out, and our team works directly with buyers to match them with form ties that fit their specific project demands.

Customization Options

Every job has its quirks – that’s why we offer ties in various lengths and diameters to work seamlessly with your existing formwork systems.

Quality Inspection Reports

No surprises – each batch ships with comprehensive testing data covering everything from tensile strength to elongation and surface quality.

Efficiency and Cost-Effectiveness

Construction is all about the bottom line. Our aluminum ties deliver by cutting labor costs and installation time through smart, streamlined design.

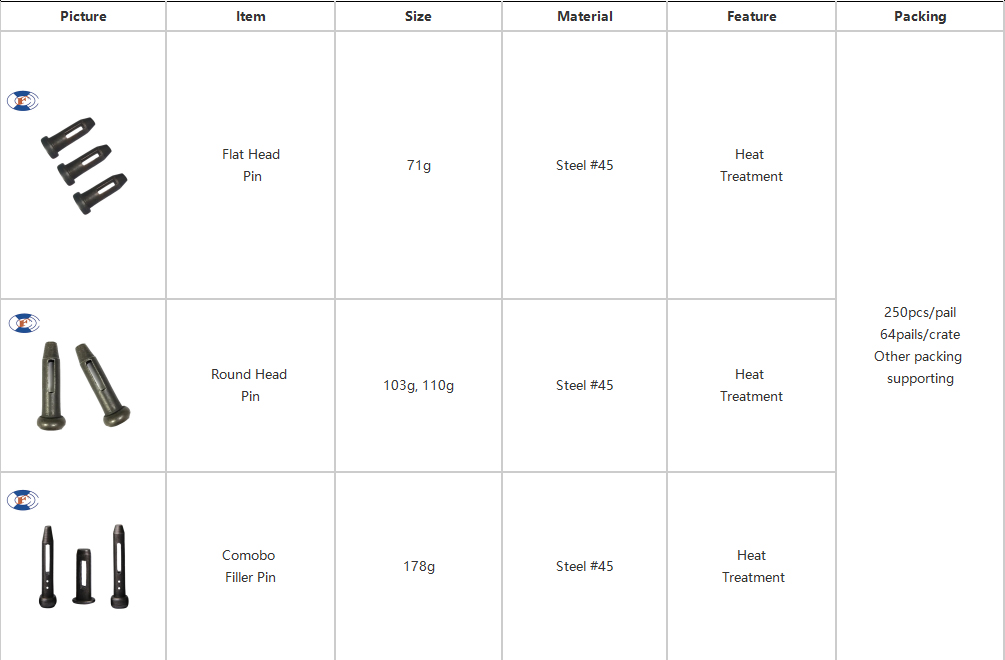

Pins and Wedges

In construction practices, aluminum form ties are commonly paired with pins and wedges to create a dependable formwork system. We offer various types to meet diverse project needs.

Flat head pin:

Ensures a secure formwork system with a flush concrete finish.

Round head pin:

Creates a strong connection with the formwork.

Combo pin:

Blending the advantages of flat and round head pins.

Straight wedge:

The go-to choice for most formwork setups.

Curved wedge:

Tailored for curved or angled formwork configurations.

As a leading manufacturer and factory supplier, Qingdao H&F is your trusted vendor and wholesaler for top-quality Concrete Forming Accessories And Rigging Hardware. With 20 years of history and expertise in this industry, we take pride in offering a wide range of products, including concrete forming full ties and nominal ties.

To solve your sourcing challenges, look no further than Qingdao H&F. We offer a comprehensive range of concrete forming accessories and rigging hardware, all backed by our two decades of experience in the industry. Whether you need full ties, nominal ties, or any other products from our catalog, we’ve got you covered.

Why Choose H&F for Aluminum Form Ties

Finding a reliable supplier matters as much as choosing the right product. Twenty years in foreign trade has taught us what construction professionals need to succeed.

Commitment to Excellence

We combine deep market knowledge with an unwavering focus on quality and service. That’s why construction pros trust us to deliver solutions that perform from groundbreaking to completion.

Conclusion

From massive infrastructure projects to modest commercial builds, aluminum form ties quietly keep concrete structures standing strong. H&F takes pride in delivering ties that exceed expectations – it’s how we’ve built our reputation for two decades and counting.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

4. Certified Excellence: CE and More for Reliable Partnerships

Related products

-

Standard Wedge Bolt

$1.00