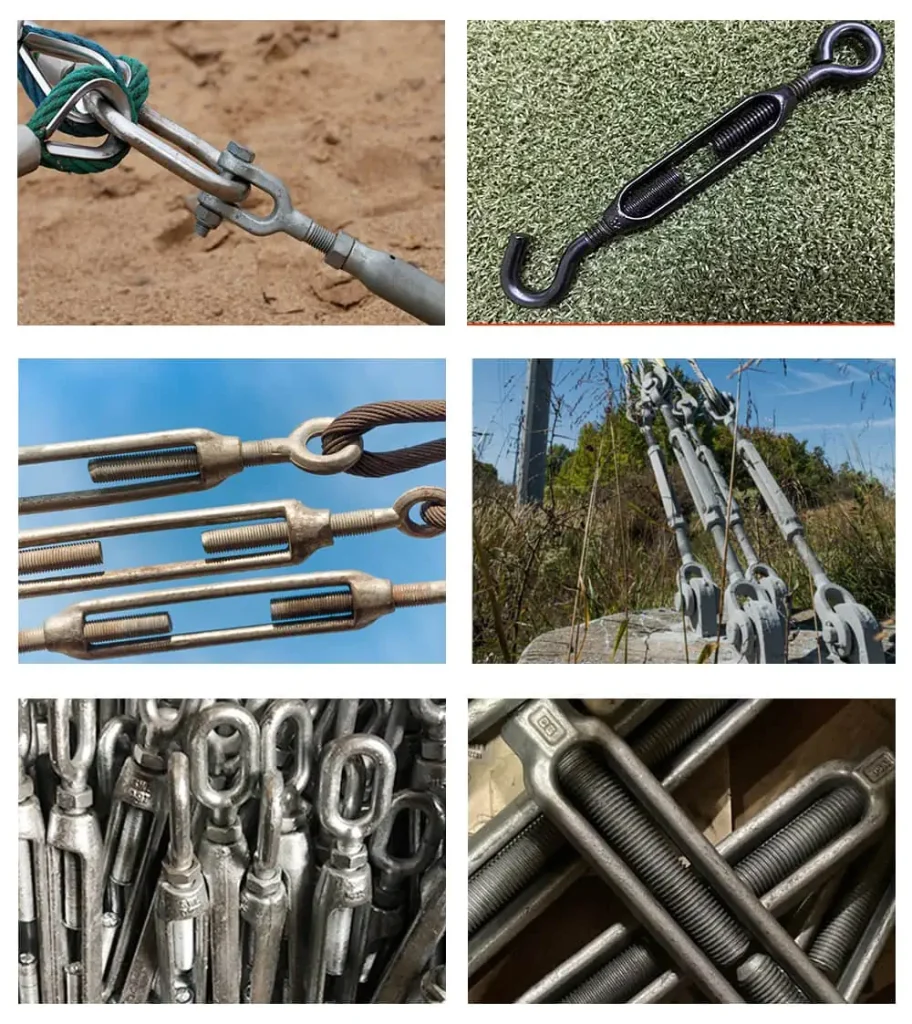

As a rigging supplier with more than 20 years of experience, turnbuckle has always been one of our best-selling products. After all, it has a wide range of application scenarios and is often used with shackle and wire rope.

Turnbuckle is a mechanical device used to adjust the tension or length of ropes, cables, rods, or other tensioning systems. It typically consists of two threaded eye bolts, hooks, or jaws, connected by a central turnbuckle body with internal screw threads that allow for the lengthening or shortening of the device. Turnbuckles are commonly used in a variety of applications, including construction, rigging, marine, and sports equipment.

After reading this article, you will have a comprehensive understanding of turnbuckle!

The Different Types of Turnbuckle

Turnbuckles come in various types, each designed for specific applications and requirements:

Body Type

Open Body Turnbuckles: These turnbuckles feature a U-shaped or open body design, allowing for easy access to the turnbuckle components for adjustment.

Closed Body Turnbuckles: Closed body turnbuckles have a tubular or enclosed body design, providing protection to the internal components from environmental elements.

Turnbuckle End Fittings and Nuts Type

Turnbuckles can be further categorized based on their end fittings and nuts:

Eye to Eye Turnbuckle:

Characteristics: This type of turnbuckle features eye fittings on both ends, allowing for easy attachment to cables, ropes, or other components using bolts, shackles, or other hardware.

Applications: Eye & Eye turnbuckles are commonly used in applications where a straight-line pull is required, such as tensioning cables, guy wires, or overhead lines.

Hook to Eye Turnbuckle:

Characteristics: Hook & Eye turnbuckles feature a hook fitting on one end and an eye fitting on the other end, providing versatility in attachment options.

Applications: These turnbuckles are suitable for applications where one end needs to be easily attachable to a hook or anchor point, while the other end requires a secure connection to a fixed point.

Hook to Hook Turnbuckle:

Characteristics: Hook & Hook turnbuckles have hook fittings on both ends, offering quick and convenient attachment to anchor points, chains, or other hardware.

Applications: They are commonly used in applications where both ends need to be easily attachable to hooks or anchor points, such as in temporary installations or rigging setups.

Jaw to Eye Turnbuckle:

Characteristics: Jaw & Eye turnbuckles feature a jaw fitting on one end and an eye fitting on the other end, providing a secure connection to fixed points while accommodating easy attachment to cables or ropes.

Applications: These turnbuckles are ideal for applications where one end needs to be securely anchored to a fixed point, while the other end requires attachment to a cable or rope.

Jaw to Jaw Turnbuckle:

Characteristics: Jaw & Jaw turnbuckles have jaw fittings on both ends, offering a secure and stable connection to cables, ropes, or other components without the need for additional hardware.

Applications: They are commonly used in applications where a strong and reliable connection is required, such as in heavy-duty rigging, marine, or construction applications.

Material Type

Galvanized Turnbuckles: Galvanized turnbuckles are coated with a layer of zinc to enhance corrosion resistance, making them suitable for outdoor or marine applications.

Stainless Steel Turnbuckles: Stainless steel turnbuckles offer superior corrosion resistance and strength, making them ideal for harsh environments or applications where aesthetics are important.

How Does Turnbuckle Work

A turnbuckle is a mechanical device designed to adjust the tension or length of ropes, cables, rods, or other tensioning systems. It consists of two threaded eye bolts, hooks, or jaws connected by a central turnbuckle body with internal screw threads. This design allows for the lengthening or shortening of the device by rotating the central body, which in turn moves the threaded components along the screw threads.

Here’s a step-by-step breakdown of how a turnbuckle works:

Threaded Components: A turnbuckle typically consists of two threaded components, often referred to as the “end fittings,” which can be eye bolts, hooks, or jaws. These threaded components are designed to engage with the internal screw threads of the turnbuckle body.

Central Turnbuckle Body: The threaded components are connected by a central turnbuckle body, which houses the internal screw threads. This body is usually cylindrical or tubular in shape and serves as the mechanism for adjusting the tension or length of the device.

Adjustment Mechanism: To adjust the tension or length of the turnbuckle, one or both of the threaded components are rotated by turning the central turnbuckle body. Rotating the body in one direction moves the threaded components inward along the screw threads, effectively shortening the overall length of the turnbuckle. Conversely, rotating the body in the opposite direction moves the threaded components outward along the screw threads, lengthening the turnbuckle.

Tensioning Action: As the threaded components move along the screw threads, they exert force on the connected components, such as ropes, cables, or rods, thereby adjusting the tension in the system. This action allows for precise tensioning of the connected components to achieve the desired level of tightness or slackness.

Locking Mechanism: Once the desired tension is achieved, locking nuts or fasteners are used to secure the position of the threaded components, preventing them from unintentionally moving and maintaining the desired tension in the system.

How to Use a Turnbuckle

Five steps to use turnbuckle:

Inspect the Turnbuckle: Before use, thoroughly inspect the turnbuckle for any signs of damage or defects to ensure safety.

Attach the Turnbuckle: Securely attach the turnbuckle to the desired anchor points using appropriate fittings.

Adjust the Length: Rotate the body of the turnbuckle to increase or decrease the length as needed.

Tighten or Loosen: Utilize the turnbuckle’s mechanisms to tighten or loosen the connection until the desired tension is achieved.

Secure the Adjustment: Once the desired tension is attained, secure the turnbuckle in place to prevent accidental loosening.

If you want to know how to use turnbuckle, read this article: How to Use a Turnbuckle.

Where are Turnbuckles Used?

Marine and Nautical Applications: Turnbuckles are extensively used in sailing and boating to tension rigging wires, ropes, and cables on sailboats, yachts, and other marine vessels. They are crucial for adjusting the tension of the sails and rigging to optimize performance and safety.

Construction and Architecture: In construction, turnbuckles are used for bracing and supporting structures like bridges, towers, and buildings. They help to maintain the stability and integrity of these structures by adjusting tension in cables and tie rods.

Aerospace and Aviation: Turnbuckles are employed in aircraft construction for controlling control surfaces like ailerons, elevators, and rudders. They ensure precise adjustment of the tension in control cables and pushrods, contributing to the safety and performance of aircraft.

Sports and Recreation: Turnbuckles are used in sports and recreational activities such as rock climbing, zip-lining, and gymnastics. They are employed in safety systems, tensioning nets, and other equipment where adjustable tension is required.

Utilities and Power Distribution: Turnbuckles find applications in utility poles and power distribution lines for maintaining proper tension in cables and wires. This helps to prevent sagging and ensures the efficient transmission of electricity.

Entertainment and Stage Rigging: In theaters, concert venues, and event spaces, turnbuckles are used in stage rigging systems to adjust the tension in curtains, lighting fixtures, and other suspended equipment. They play a crucial role in ensuring the safety and stability of overhead installations.

Fencing and Trellising: Turnbuckles are used in fencing and trellising systems for agriculture, vineyards, and landscaping. They help to maintain the tension in wires and supports, ensuring the stability of fences and trellises.

Industrial and Mechanical Engineering: Turnbuckles are employed in various industrial and mechanical applications where adjustable tensioning is required. They are used in conveyor systems, hoists, lifting equipment, and tensioning devices for belts and chains.

Conclusion about Turnbuckle

In conclusion, turnbuckles are versatile mechanical devices used for adjusting the tension or length of tensioning systems in a wide range of applications. With various types, end fittings, and materials available, turnbuckles offer flexibility and reliability in tensioning solutions.

FAQS about Turnbuckle

1. How do I choose the right size turnbuckle for my application?

The size of the turnbuckle depends on factors such as the load capacity and desired tension. Refer to manufacturer specifications and guidelines for selecting the appropriate size.

2. Can turnbuckles be used in outdoor environments?

Yes, galvanized or stainless steel turnbuckles are suitable for outdoor applications as they offer corrosion resistance against environmental elements.

3. What is the maximum tension capacity of a turnbuckle?

The maximum tension capacity varies depending on the type and size of the turnbuckle. Refer to manufacturer specifications for exact capacity ratings.

4. Can turnbuckles be used for lifting applications?

Turnbuckles are not designed for lifting heavy loads. It’s recommended to use dedicated lifting equipment for such applications.

5. How often should turnbuckles be inspected for wear and tear?

Regular visual inspections should be conducted to check for signs of wear, corrosion, or damage. Replace any worn or damaged turnbuckles immediately to prevent safety hazards.

6. Can turnbuckles be used for angular adjustments?

Turnbuckles are primarily designed for linear tensioning applications. For angular adjustments, additional hardware or specialized fittings may be required.

7. Are turnbuckles reusable?

Yes, turnbuckles are reusable as long as they are in good condition and properly maintained. Inspect turnbuckles before reuse to ensure they meet safety standards.

8. Can turnbuckles be used in high-temperature environments?

Stainless steel turnbuckles can withstand higher temperatures compared to galvanized turnbuckles. However, it’s important to consider the specific temperature limits of the materials used.

9. How do I prevent turnbuckles from seizing or getting stuck?

Apply a lubricant or anti-seize compound to the threads and moving parts of the turnbuckle to prevent seizing or corrosion.

10. Can turnbuckles be used for overhead applications?

Yes, turnbuckles can be used for overhead applications, but it’s essential to ensure proper installation and secure anchoring to prevent accidents or injuries.