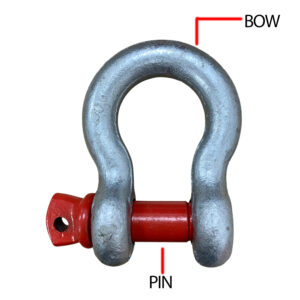

A shackle, the most common type of rigging, is a metal fastening device used to connect, lift and secure loads in a variety of industrial applications. It is usually a ring with a pin or bolt in the opening that provides a secure attachment point. It is an essential tool in various industries and is a versatile connector for lifting, hoisting and securing loads.

In fact shackle can be found everywhere in our lives. Let’s delve into the world of shackles with this blog and learn about their types, uses and importance in different situations!

Types of Shackles

1. Bow Shackle (Anchor Shackle)

Bow shackles, also known as anchor shackles, are characterized by their U-shaped design with a rounded bow shape. This design allows for a larger loop, providing ample space for multiple connections or attachment points. Bow shackles are commonly used in applications where versatility and flexibility are required, such as lifting and rigging operations in construction, marine, and industrial settings.

Common Models:

G209: This model is a general-purpose bow shackle suitable for various lifting and rigging applications. It features a galvanized finish for corrosion resistance.

G213: Designed for more demanding applications, the G213 bow shackle offers a higher working load limit (WLL) and increased strength compared to the G209 model.

G2130: The G2130 bow shackle is a high-capacity model designed for heavy-duty lifting and rigging tasks. It offers a higher working load limit (WLL) and increased strength compared to standard bow shackles.

G2140: Similar to the G2130 model, the G2140 bow shackle is designed for heavy-duty lifting and rigging applications. It features a larger size and higher working load limit (WLL) to accommodate larger loads.

2. D Shackle (Chain Shackle)

D shackles, also referred to as chain shackles, feature a D-shaped design with straight sides and a curved shape. This design provides a more secure connection compared to bow shackles, making D shackles ideal for applications where safety is paramount. D shackles are commonly used in lifting and rigging operations in construction, mining, and oil and gas industries.

Common Models:

G210: The G210 D shackle is a general-purpose model suitable for various lifting and rigging applications. It features a hot-dip galvanized finish for corrosion resistance.

G2150: This model is a high-capacity D shackle designed for heavy-duty lifting and rigging tasks. It offers a higher working load limit (WLL) and increased strength compared to the G210 model.

3. Screw Pin Shackle

Screw pin shackles feature a threaded pin that screws into the shackle body for secure fastening. This design allows for quick and easy installation without the need for additional tools. Screw pin shackles are commonly used in applications where frequent connection and disconnection are required, such as rigging, towing, and general lifting operations.

Common Models:

G209: The G209 screw pin shackle is a general-purpose model suitable for various light to medium-duty lifting and rigging applications. It features a hot-dip galvanized finish for corrosion resistance.

G210: Designed for more demanding applications, the G210 screw pin shackle offers a higher working load limit (WLL) and increased strength compared to the G209 model.

4. Bolt-Type Shackle

Bolt-type shackles feature a bolt secured by a nut, providing a robust and secure connection. This design offers enhanced stability and safety, making bolt-type shackles suitable for heavy-duty lifting and rigging applications in construction, mining, and industrial settings. Bolt-type shackles are commonly used in applications where high loads and demanding conditions are encountered.

Common Models:

G2130: This model is a high-capacity bolt-type shackle designed for heavy-duty lifting and rigging tasks. It offers a higher working load limit (WLL) and increased strength compared to standard bolt-type shackles.

G2140: Similar to the G2130 model, the G2140 bolt-type shackle is designed for heavy-duty lifting and rigging applications. It features a larger size and higher working load limit (WLL) to accommodate larger loads.

5. Round Pin Shackle

Round pin shackles feature a simple pin that fits through the shackle body, providing a quick and easy connection. This design allows for fast installation and removal without the need for additional tools, making round pin shackles ideal for temporary or non-critical applications where frequent assembly and disassembly are required.

Common Models:

G213: The G213 round pin shackle is a general-purpose model suitable for various light to medium-duty lifting and rigging applications. It features a hot-dip galvanized finish for corrosion resistance.

G215: Designed for more demanding applications, the G215 round pin shackle offers a higher working load limit (WLL) and increased strength compared to the G213 model.

What are Shackles Used For

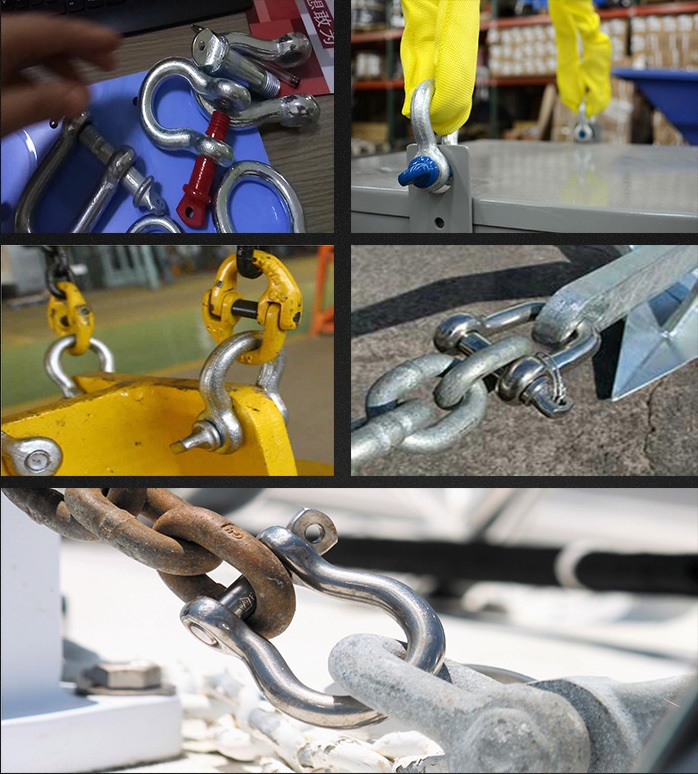

Shackles are used across various industries for lifting, rigging, towing, and securing loads. They are vital components in construction, maritime, mining, and transportation sectors. Common applications include:

Lifting heavy machinery and equipment

Rigging sailboats and securing sails

Connecting chains and cables in towing operations

Anchoring and securing loads in construction sites

Supporting overhead loads in material handling

Shackles play a crucial role in ensuring safety, efficiency, and reliability in lifting and rigging operations.

Usage in Construction

Shackles are widely used in construction for lifting heavy materials, securing scaffolding, and anchoring loads. They provide a strong and reliable connection point, enhancing safety and efficiency on construction sites.

Maritime Applications

In maritime settings, shackles are indispensable for rigging sails, securing anchor lines, and connecting ropes and chains on ships. Their robust construction and corrosion resistance make them ideal for marine environments.

Industrial Rigging

In industrial settings, shackles are essential for rigging and lifting operations, supporting heavy machinery, and securing loads during transportation. Their versatility and durability make them indispensable tools in various industrial applications.

Conclusion about Shackles

Shackles are indispensable tools in lifting, rigging, and securing loads across various industries. With their diverse types and robust construction, they provide reliable connections, enhance safety, and ensure efficiency in various applications. Understanding the different types of shackles and their uses is essential for selecting the right tool for specific tasks, ensuring optimal performance and safety.

FAQs about Shackles

1. How do I determine the working load limit of a shackle?

The working load limit (WLL) of a shackle is typically marked on its body and represents the maximum weight it can safely lift or hold. It’s essential to check the manufacturer’s specifications and never exceed the rated WLL to ensure safety.

2. Can shackles be used for overhead lifting?

Yes, shackles can be used for overhead lifting when properly rated and used within their specified working load limits. It’s crucial to inspect shackles regularly for wear and damage and replace them if any signs of wear are detected.

3. What is the difference between a bow shackle and a D shackle?

Bow shackles have a rounded shape resembling a bow, while D shackles have a D-shaped design. Bow shackles offer a larger loop for attachment points, while D shackles provide a more secure connection due to their straight sides.

4. Can I use a screw pin shackle for critical lifting applications?

Screw pin shackles are suitable for non-critical applications and should not be used for critical lifting operations where the load may cause the pin to unscrew. For critical lifting, consider using bolt-type shackles for added security.

5. How should I store shackles when not in use?

Shackles should be stored in a dry, clean environment away from moisture and corrosive elements. It’s recommended to store them in a designated rack or container to prevent damage and ensure easy access when needed.

6. Are stainless steel shackles suitable for marine environments?

Yes, stainless steel shackles are ideal for marine environments due to their corrosion resistance and durability. They provide reliable performance in saltwater conditions and are commonly used in maritime applications.

7. Can shackles be used for towing vehicles?

Yes, shackles are commonly used for towing vehicles when properly rated and used within their specified working load limits. It’s important to ensure that the shackle and towing equipment are in good condition and properly secured to prevent accidents.

8. What is the difference between a bolt-type shackle and a round pin shackle?

Bolt-type shackles have a bolt secured by a nut for a robust and secure connection, while round pin shackles feature a simple pin that fits through the shackle body. Bolt-type shackles offer added security, while round pin shackles provide quick and easy connections.

9. Can shackles be used for lifting personnel?

No, shackles should not be used for lifting personnel due to safety concerns. Dedicated lifting equipment designed for personnel lifting, such as harnesses and platforms, should be used to ensure safety and compliance with regulations.

10. How often should shackles be inspected for wear and damage?

Shackles should be inspected before each use and regularly during service for signs of wear, deformation, or damage. It’s important to follow the manufacturer’s recommendations and industry standards for inspection intervals to ensure safety and reliability.