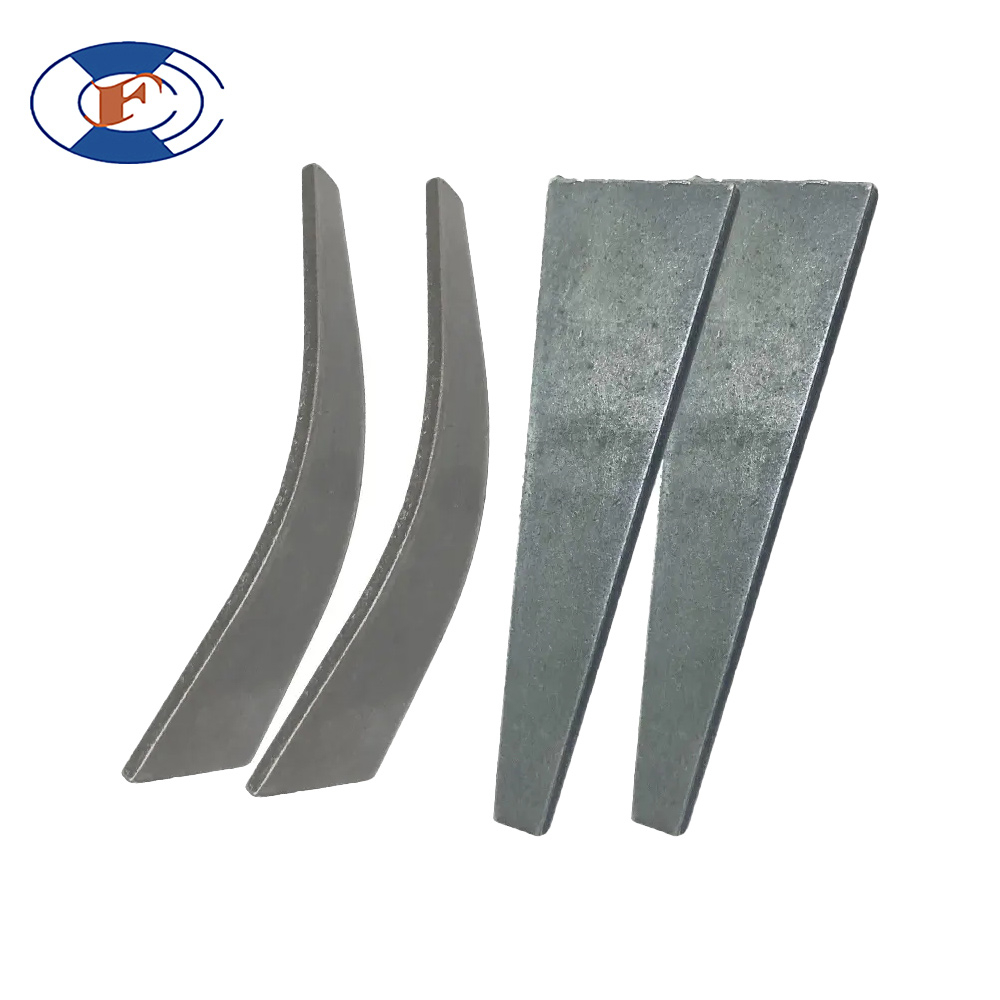

Concrete Form Curved Wedge Straight Wedge

The Concrete Curved Wedge Straight Wedge, paired with the x flat tie, offers a sophisticated solution for precise concrete alignment and support in construction projects. Engineered from high-grade, durable materials, these wedges and ties ensure exceptional strength, longevity, and a secure fit. They are meticulously designed for both aesthetic appeal and functional performance, meeting rigorous quality control tests and holding relevant certifications. This product line represents the perfect blend of innovation and reliability in modern construction technology.

In the demanding world of construction, accuracy and durability are paramount. The performance of concrete formwork largely depends on the accessories used, and the Straight Wedge and Bend Wedge have emerged as indispensable tools. These products stand out by providing tailored solutions that guarantee precise alignment and secure installation. While both wedges serve critical roles, each boasts distinct features that cater to specific challenges encountered in various construction environments. This article presents an in-depth analysis of the Straight Wedge and Bend Wedge, detailing their construction, applications, and benefits, all while upholding the highest standards of quality and customer service.

| Aluminum Forming System Accessories | ||||

|---|---|---|---|---|

| Picture | Item | Size | Material | Feature |

| Flat Head Pin | 71g | Steel #45 | Heat Treatment |

| Round Head Pin | 103g | Steel #45 | Heat Treatment |

| Comobo Pin | 178g | Steel #45 | Heat Treatment |

| Straight Wedge | 49.2g | Steel #45 | Heat Treatment |

| Curved Wedge | 49.4g | Steel #45 | Heat Treatment |

Standard X Flat Tie

| Size | Unit | Pallet | Weight (kg) | Ultimate load |

|---|---|---|---|---|

| 4" | 100pcs/box | 10000pcs/pallet | 0.1040 | 6000lbs |

| 6" | 100pcs/box | 10000pcs/pallet | 0.1198 | 6000lbs |

| 8" | 100pcs/box | 10000pcs/pallet | 0.1412 | 6000lbs |

| 10" | 100pcs/box | 10000pcs/pallet | 0.1626 | 6000lbs |

| 12" | 100pcs/box | 10000pcs/pallet | 0.1840 | 6000lbs |

| 14" | 100pcs/box | 5000pcs/pallet | 0.2054 | 6000lbs |

| 16" | 100pcs/box | 5000pcs/pallet | 0.2268 | 6000lbs |

| 18" | 50pcs/bundle | 5000pcs/pallet | 0.2482 | 6000lbs |

| 20" | 50pcs/bundle | 2500pcs/pallet | 0.2696 | 6000lbs |

| 22" | 50pcs/bundle | 2500pcs/pallet | 0.2910 | 6000lbs |

Heavt Duty X Flat Tie

| Size | Unit | Pallet | Weight (kg) | Ultimate Load (lbs) |

|---|---|---|---|---|

| 4" | 100pcs/box | 10000pcs/pallet | 0.1240 | 7000 |

| 6" | 100pcs/box | 10000pcs/pallet | 0.1429 | 7000 |

| 8" | 100pcs/box | 10000pcs/pallet | 0.1684 | 7000 |

| 10" | 100pcs/box | 10000pcs/pallet | 0.1939 | 7000 |

| 12" | 100pcs/box | 10000pcs/pallet | 0.2195 | 7000 |

| 14" | 100pcs/box | 5000pcs/pallet | 0.2450 | 7000 |

| 16" | 100pcs/box | 5000pcs/pallet | 0.2705 | 7000 |

| 18" | 50pcs/bundle | 5000pcs/pallet | 0.2960 | 7000 |

| 20" | 50pcs/bundle | 2500pcs/pallet | 0.3215 | 7000 |

| 22" | 50pcs/bundle | 2500pcs/pallet | 0.3470 | 7000 |

Straight Wedge Overview

The Straight Wedge serves as a cornerstone in ensuring uniformity and stability in concrete formwork systems. Constructed from high-tensile alloy steel, it offers unmatched rigidity and load-bearing capacity, making it ideal for maintaining a perfectly aligned structure. The design emphasizes simplicity and functionality; its flat surface and precise angles distribute pressure evenly across the formwork. This feature minimizes deformation and ensures a secure fit between components, even in high-pressure scenarios. Quality control measures and certification standards validate the Straight Wedge’s ability to deliver consistent performance, ensuring that it meets the rigorous demands of modern construction projects. The straightforward yet robust design allows for both standard and customized configurations, providing flexibility to match project-specific requirements without compromising on quality.

Bend Wedge Overview

In contrast to its straight counterpart, the Bend Wedge offers an innovative solution for formwork systems that require angular adjustments and dynamic positioning. Designed with a subtly curved profile, the Bend Wedge accommodates the need for non-linear alignments in complex structures. Its construction utilizes advanced composite materials in conjunction with high-strength alloy steel, achieving a delicate balance between flexibility and durability. This design ensures that the wedge can adjust to varying angles while maintaining the integrity of the formwork. The meticulous engineering process behind the Bend Wedge involves precise calibration of its curvature to distribute stresses effectively, ensuring that the concrete setting process remains undisturbed. Certification from quality control agencies underscores its reliability, making it a trusted choice for projects where adaptability and precision converge.

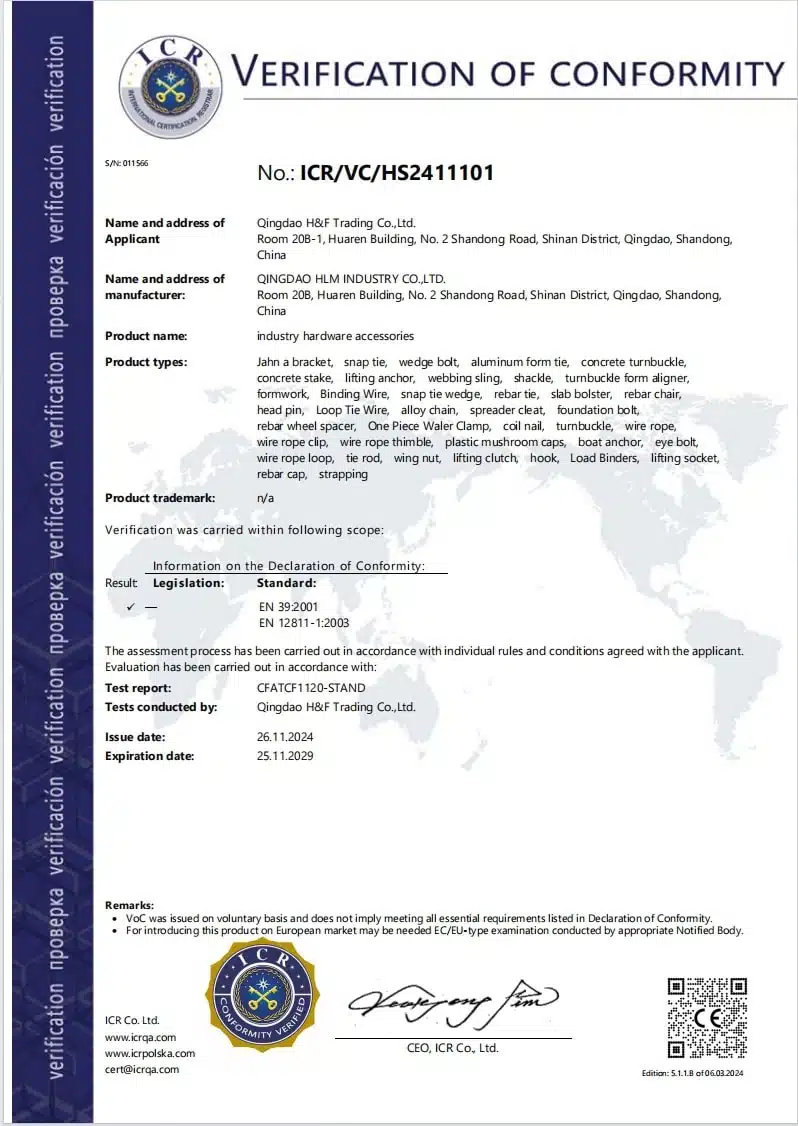

Material Composition and Certification

At the core of the Concrete Bend Wedge Straight Wedge lies high-tensile alloy steel that provides exceptional strength and resilience. Manufacturers utilize materials that resist corrosion and withstand significant stress, ensuring that the wedge maintains its structural integrity over time. Complementing this, the x-flat tie incorporates advanced composite elements that strike a balance between flexibility and rigidity. This thoughtful selection of materials not only contributes to the longevity of the system but also ensures that each component meets rigorous quality control tests. Certification by internationally recognized agencies further substantiates the reliability and safety of these products, reinforcing confidence in their performance in diverse construction settings.

Technical Specifications and Applications

Precision defines the design of the Concrete Bend Wedge Straight Wedge. With carefully engineered dimensions and tolerances, the wedge facilitates accurate load distribution across the formwork, thereby preventing misalignments and structural deformations during the concrete curing process. The x-flat tie, designed to seamlessly integrate with the wedge, offers a secure connection that minimizes the potential for slippage or misalignment. This pair finds its application in a variety of projects, from the assembly of precast concrete elements to extensive infrastructure developments. The product parameters, including dimensional accuracy, weight capacity, and load-bearing characteristics, have been meticulously optimized based on thorough field testing and engineering analysis. Each unit undergoes strict quality evaluations, ensuring that the accessories consistently perform under the challenging conditions typical of modern construction environments.

Design Innovation and Quality Assurance

Innovation drives the continuous improvement of the wedge and tie system. Engineers incorporate advanced computer-aided design techniques to refine each detail, ensuring that the components deliver on both performance and ease of use. The manufacturing process embraces precision machining and modern fabrication methods that allow for consistent replication of the finely tuned specifications. In doing so, the system not only meets but often exceeds the expectations of construction professionals. The emphasis on quality assurance is evident in every stage of production, from the selection of materials to the final inspection. Each product passes through comprehensive testing phases that evaluate both its physical and mechanical properties, culminating in accessories that embody both robust design and meticulous craftsmanship.

Partnership and Service Excellence

Beyond the technical merits of the Concrete Bend Wedge Straight Wedge and x-flat tie, the collaborative advantages provided by H&F add significant value for buyers. By choosing to work with H&F, clients gain access to free samples that allow for hands-on evaluation of the product’s performance before a full-scale commitment. One-to-one customer service ensures that every inquiry is handled with expert attention, providing customized solutions that address specific project requirements. Additionally, the door-to-door delivery service underscores a commitment to efficiency and reliability, streamlining the procurement process and ensuring that materials arrive promptly and safely. These advantages make H&F a trusted partner in the competitive market of concrete form accessories and rigging hardware, offering a blend of technical expertise and exceptional service.

The Concrete Bend Wedge Straight Wedge, in combination with the matching x-flat tie, represents a well-considered solution for enhancing the performance of concrete formwork systems. The detailed attention to material quality, precise engineering, and rigorous quality control results in a product that construction professionals can rely on under even the most demanding circumstances. By integrating state-of-the-art design with a commitment to customer satisfaction, this system not only meets but often surpasses the expectations of its users. With a focus on real-world applications and a deep understanding of construction dynamics, these accessories provide an invaluable contribution to building projects that demand precision and durability.

What sets us apart

1. Dedicated, 24/7 One-on-One Customer Service

Our team is available around the clock to provide personalized support and promptly address any questions or concerns, ensuring a smooth and reliable experience.

2. Extensive Inventory, Competitive Pricing, and Free Samples

We maintain a robust inventory to support fast, reliable fulfillment. Our competitive prices and free samples allow you to assess quality firsthand, ensuring timely and dependable delivery within each project cycle.

3. Rigorous Quality Control and Comprehensive Inspection Reports

Our strict quality inspection process ensures all products meet the highest standards. Every order is backed by detailed test reports, delivering peace of mind and consistent quality assurance.

4. Certified Excellence: CE and More for Reliable Partnerships

Corporate Profile

Established in 2000, QINGDAO H&F CORP is a globally recognized provider of engineered industrial hardware solutions. We specialize in the design, manufacturing, and worldwide distribution of certified hardware for concrete construction, rigging systems, and precast applications. Over two decades of operation have cemented our commitment to delivering cost-optimized, standards-compliant solutions to engineering firms, contractors, and distributors across 70+ countries.

Core Capabilities Statement

Product Certification & Compliance

All structural hardware products are CE certified in accordance with applicable EU directives, validated through independent testing protocols. Certification encompasses rigorous verification of load ratings, corrosion resistance, and safety performance against EN/ISO benchmarks. Full traceability from raw materials to finished goods is maintained through our ISO 9001:2015-certified quality management system.

Commercial Operations

We offer market-competitive pricing structures with negotiable project-based procurement terms, accommodating flexible payment arrangements including Letters of Credit (LC), Telegraphic Transfers (TT), and Open Account (OA) solutions. Our zero Minimum Order Quantity (MOQ) policy ensures equal service standards for single-unit prototypes and bulk industrial orders.

Global Logistics Network

Comprehensive door-to-door shipping solutions are executed under DAP/DDP Incoterms® 2020, featuring:

Multi-modal transport coordination (FCL/LCL)

ISTA 3E-compliant export packaging

Pre-validated customs documentation

Real-time GPS-enabled shipment tracking

Service coverage extends from our 40,000m² Qingdao manufacturing hub to destination warehouses worldwide, with average transit times of 25 days to North American ports and 32 days to European terminals.

Related products

-

Flat Stacking Tie

$0.01