Symons Concrete Forms are innovative formwork systems used in the construction industry to mold concrete into specific shapes and structures. These forms are crucial in creating precise and consistent concrete elements for a variety of projects, ranging from commercial buildings to residential foundations. Symons Concrete Forms are well-known for their strength, reusability, and ease of assembly, making them a go-to choice for many contractors and builders.

The Symons formwork system includes several components and accessories designed to work together seamlessly. These include steel and aluminum formworks, wedge bolts, wedge pins, one-piece waler brackets, turnbuckle form aligners, spreader cleats, tie holders, aluminum and steel form ties, and steel stakes. Together, these components create a robust and reliable system for shaping and supporting concrete during the curing process.

What are Symons Concrete Forms Systems

Symons Concrete Forms Systems are engineered solutions specifically designed to provide support and shape to concrete structures as they are being poured and cured. These systems are composed of modular formwork panels and a range of accessories, all of which work together to ensure that the concrete retains its intended shape and size. Symons Concrete Forms Systems are available in both steel and aluminum variants, each offering unique benefits.

Steel Formwork: Steel formwork is renowned for its durability and strength, making it ideal for large-scale projects that require high load-bearing capacity. Steel forms are typically used in commercial and industrial construction, where the demands for structural integrity are high. The smooth surface of steel formwork produces a flawless finish on the concrete surface, reducing the need for additional finishing work.

Aluminum Formwork: Aluminum formwork is a lightweight alternative to steel, making it easier to handle and install on site. Despite its lighter weight, aluminum formwork is incredibly strong and durable. It is also corrosion-resistant, which extends its lifespan and makes it suitable for use in environments where moisture or chemicals might be a concern. Aluminum formwork is often preferred for residential construction or smaller commercial projects due to its ease of use and efficiency in assembly and disassembly.

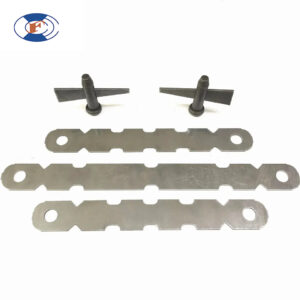

Wedge Bolt and Wedge Pin: The wedge bolt and wedge pin are critical components in the Symons Concrete Forms System. The wedge bolt is inserted through holes in the formwork panels, and the wedge pin is driven into the bolt to lock the panels together securely. This connection ensures that the formwork panels remain tightly in place during the concrete pour, preventing leaks and maintaining the integrity of the structure.

One-Piece Waler Bracket: The one-piece waler bracket is used to reinforce and align the formwork panels, ensuring that they remain properly positioned during the concrete pour. This bracket is especially useful in maintaining the alignment of taller formwork panels, which are more prone to shifting under the weight of the concrete.

Turnbuckle Form Aligner: The turnbuckle form aligner is an essential tool for adjusting the alignment of the formwork panels. By turning the buckle, workers can make fine adjustments to the position of the panels, ensuring that they are level and plumb. This precision is crucial for achieving a high-quality finished product.

Spreader Cleats: Spreader cleats are crucial for maintaining the correct spacing between formwork panels. These devices are inserted between panels to prevent them from bowing or bulging under the pressure of wet concrete. Spreader cleats ensure that the panels remain parallel and aligned, which is essential for producing uniform and accurate concrete structures. By keeping the formwork panels evenly spaced, spreader cleats help achieve a consistent thickness and shape in the final concrete product.

Z Tie Holder: The Z tie holder is a specific type of accessory used to secure form ties in place within the formwork system. These holders are designed to lock the form ties, which connect opposing sides of the formwork, preventing the panels from spreading apart during the concrete pour. The Z tie holder plays a critical role in maintaining the stability and integrity of the formwork system, ensuring that the concrete structure is formed precisely as intended. With the Z tie holder, the risk of formwork failure or deformation is significantly reduced, resulting in a smoother and more successful construction process.

Aluminum Form Tie: Aluminum form ties are used to hold opposing sides of the formwork together. They are lighter and easier to handle than steel form ties, making them ideal for projects where quick setup and takedown are required. Despite their lightweight nature, aluminum form ties are strong and provide adequate resistance to the pressure exerted by wet concrete.

Snap Tie: A snap tie is a form tie specifically designed to be easily broken or “snapped” off after the concrete has set. Snap ties are used in conjunction with the snap tie wedge, which holds the tie securely in place during the pour. The snap tie system is efficient and cost-effective, allowing for quick removal of the formwork without leaving large holes or requiring extensive patching.

Jahn A Bracket: The Jahn A Bracket is a versatile and essential component in the Symons system, used to secure the formwork panels and maintain their alignment during the pour. The bracket works in conjunction with snap ties, providing additional support and ensuring that the panels remain properly aligned and secure. The Jahn A Bracket’s design allows for easy adjustment and removal, making it a practical choice for a variety of concrete forming applications.

Steel Stakes: Steel stakes are used to anchor the formwork panels to the ground, preventing them from shifting during the concrete pour. The stakes are driven into the ground along the base of the formwork, providing stability and ensuring that the panels remain in place throughout the curing process.

Symons Concrete Forms Systems are designed to be versatile, allowing them to be used in a wide range of construction projects. Whether you’re building a high-rise skyscraper or a simple residential foundation, these formwork systems provide the reliability and precision needed to achieve a high-quality result.

How to Install Symons Concrete Forms

Proper installation of Symons Concrete Forms is critical to ensuring the success of your concrete construction project. The following steps outline the process for installing Symons Concrete Forms, including tips on how to use the various components effectively.

1. Site Preparation

Before installing Symons Concrete Forms, you must prepare the construction site. This includes clearing the area of debris, vegetation, and any obstructions that could interfere with the installation process. The ground should be leveled and compacted to provide a stable foundation for the formwork. In some cases, it may be necessary to excavate the site to the required depth before beginning the installation.

2. Layout and Measurement

Once the site is prepared, you will need to mark out the layout of the concrete structure. This involves measuring and marking the dimensions of the structure on the ground, ensuring that all corners and edges are square. Accurate measurements are crucial at this stage, as any errors will be reflected in the final structure. Use stakes and string lines to mark the layout, making sure that all lines are straight and level.

3. Setting Up Formwork Panels

With the layout in place, you can begin setting up the Symons formwork panels. Start by placing the panels along the marked lines, making sure that they are aligned with the layout. Use wedge bolts and wedge pins to secure the panels together, creating a tight and stable connection. As you install each panel, check that it is level and plumb, using a level and a plumb bob as needed. If the panels are not properly aligned, the finished concrete structure may be uneven or out of square.

4. Using Turnbuckle Form Aligners

After the formwork panels are in place, use turnbuckle form aligners to make any necessary adjustments. The turnbuckle aligners allow you to fine-tune the alignment of the panels, ensuring that they are perfectly level and plumb. This step is particularly important for taller formwork panels, which can be more difficult to align by hand. By making small adjustments with the turnbuckle aligners, you can ensure that the panels are set up correctly, reducing the risk of errors in the final structure.

5. Installing Spreader Cleats and Tie Holders

Once the formwork panels are aligned, you will need to install spreader cleats and tie holders. Spreader cleats are placed between the panels to maintain the correct spacing and prevent them from bowing under the pressure of the wet concrete. Tie holders are used to secure the form ties, which connect the opposite sides of the formwork and resist the lateral pressure exerted by the concrete. Make sure that all spreader cleats and tie holders are properly installed and secure before proceeding to the next step.

6. Inserting Form Ties

With the spreader cleats and tie holders in place, you can insert the form ties. The form ties should be inserted through the tie holders and secured tightly. These ties are critical for maintaining the integrity of the formwork during the concrete pour, as they prevent the panels from separating or bulging. Make sure that all ties are properly tightened and that there are no gaps or weak points in the formwork.

7. Securing with Steel Stakes

To further secure the formwork, drive steel stakes into the ground along the base of the panels. The stakes should be placed at regular intervals, providing additional stability and preventing the formwork from shifting during the concrete pour. Use a hammer or stake driver to drive the stakes into the ground, making sure that they are firmly embedded and that the formwork is securely anchored.

8. Final Check

Before pouring the concrete, perform a final check of the formwork to ensure that everything is properly aligned and secured. Double-check that all panels are level and plumb, that the spreader cleats and tie holders are in place, and that the form ties are tight. This is your last opportunity to make any adjustments before the concrete is poured, so take the time to ensure that everything is correct.

9. Pouring the Concrete

Once you are satisfied with the formwork setup, you can begin pouring the concrete. Pour the concrete evenly into the formwork, making sure that it fills all spaces and that there are no voids or air pockets. Use a vibrator or a tamping rod to compact the concrete and ensure that it is evenly distributed. Continue pouring until the formwork is filled to the desired height.

10. Curing and Removing the Forms

After the concrete has been poured, allow it to cure according to the manufacturer’s instructions. Curing times can vary depending on the type of concrete used and the environmental conditions. Once the concrete has cured, you can begin removing the formwork panels. Start by removing the wedge bolts and pins, then carefully disassemble the panels. Be sure to clean the formwork components thoroughly after use, as this will extend their lifespan and ensure that they are ready for the next project.

How Thick is a Symons Form?

The thickness of a Symons form is an important consideration in determining its suitability for a particular project. The thickness can vary depending on the type of formwork and the material used, and it plays a key role in the strength and durability of the form.

Steel Forms: Symons steel forms are typically available in thicknesses ranging from 0.125 inches to 0.25 inches. Thicker steel forms are stronger and more resistant to deformation, making them ideal for projects that require high load-bearing capacity. The exact thickness of the steel form will depend on the specific requirements of the project, including the size and shape of the concrete structure, as well as the pressure exerted by the wet concrete.

Aluminum Forms: Symons aluminum forms are generally available in thicknesses ranging from 0.08 inches to 0.125 inches. While aluminum forms are not as strong as steel forms, they are still highly durable and provide excellent resistance to corrosion. The lighter weight of aluminum forms makes them easier to handle and install, but it is important to choose the appropriate thickness to ensure that the form can withstand the pressure of the concrete.

Specialty Forms: In addition to standard steel and aluminum forms, Symons also offers specialty forms with varying thicknesses to meet the unique needs of different projects. These specialty forms may include additional reinforcement or be made from alternative materials, such as fiberglass or plastic, to provide specific performance characteristics.

The thickness of a Symons form should be carefully selected based on the specific requirements of the project. Thicker forms provide greater strength and durability, but they may also be heavier and more difficult to handle. Thinner forms are lighter and easier to work with, but they may not be suitable for projects that require high load-bearing capacity.

Conclusion about Symons Concrete Form

Symons Concrete Forms are an essential tool for any concrete construction project. Whether you are building a commercial structure, a residential foundation, or any other concrete element, these formwork systems provide the strength, durability, and precision needed to achieve a high-quality result. By understanding the components of Symons Concrete Forms Systems, how to install them properly, and the importance of selecting the right thickness for your forms, you can ensure the success of your project and create structures that stand the test of time.

FAQs about Symons Concrete Forms

1. What are Symons Concrete Forms made of?

Symons Concrete Forms are typically made of steel or aluminum, though specialty forms may be made of alternative materials like fiberglass or plastic.

2. How long can Symons Concrete Forms be reused?

With proper care and maintenance, Symons Concrete Forms can be reused multiple times, making them a cost-effective choice for many projects.

3. Can Symons Concrete Forms be customized?

Yes, Symons Concrete Forms can be customized to meet the specific needs of your project. Custom forms can be made in various sizes, shapes, and thicknesses.

4. Are Symons Concrete Forms easy to install?

Yes, Symons Concrete Forms are designed for ease of installation. The modular design and lightweight materials make them easy to handle and assemble on site.

5. What are the benefits of using Symons Concrete Forms?

Symons Concrete Forms offer several benefits, including durability, reusability, ease of installation, and the ability to create precise and consistent concrete structures.

6. How do I maintain Symons Concrete Forms?

To maintain Symons Concrete Forms, clean them thoroughly after each use, store them in a dry and protected area, and inspect them regularly for any signs of damage or wear.

7. Can Symons Concrete Forms be used for curved structures?

Yes, Symons Concrete Forms can be used for curved structures with the appropriate formwork components and accessories.

8. What is the weight capacity of Symons Concrete Forms?

The weight capacity of Symons Concrete Forms depends on the thickness and material of the formwork. Steel forms generally have a higher weight capacity than aluminum forms.

9. Are Symons Concrete Forms compatible with other formwork systems?

Symons Concrete Forms are designed to be compatible with other formwork systems, allowing for flexibility and versatility in your construction projects.

10. Where can I purchase Symons Concrete Forms?

Symons Concrete Forms can be purchased from authorized dealers and distributors. It is important to work with a reputable supplier to ensure that you receive high-quality forms and accessories.