What Is A Snap Tie

In the world of concrete construction, the term “Snap Tie” might sound like jargon to the uninitiated. However, for those involved in the industry, Snap Ties play a crucial role in ensuring the structural integrity and stability of concrete forms.

In this article, we’ll delve into what Snap Ties are and introduce you to two essential variations: the Concrete Snap Tie with Washer and the Concrete Snap Ties with Plastic Cone.

Snap tie is also one of H&F’s highest-selling products. Below is a video of the snap tie and the assembly of the wedge and jahn bracket.

Understanding Snap Ties: The Backbone of Formwork

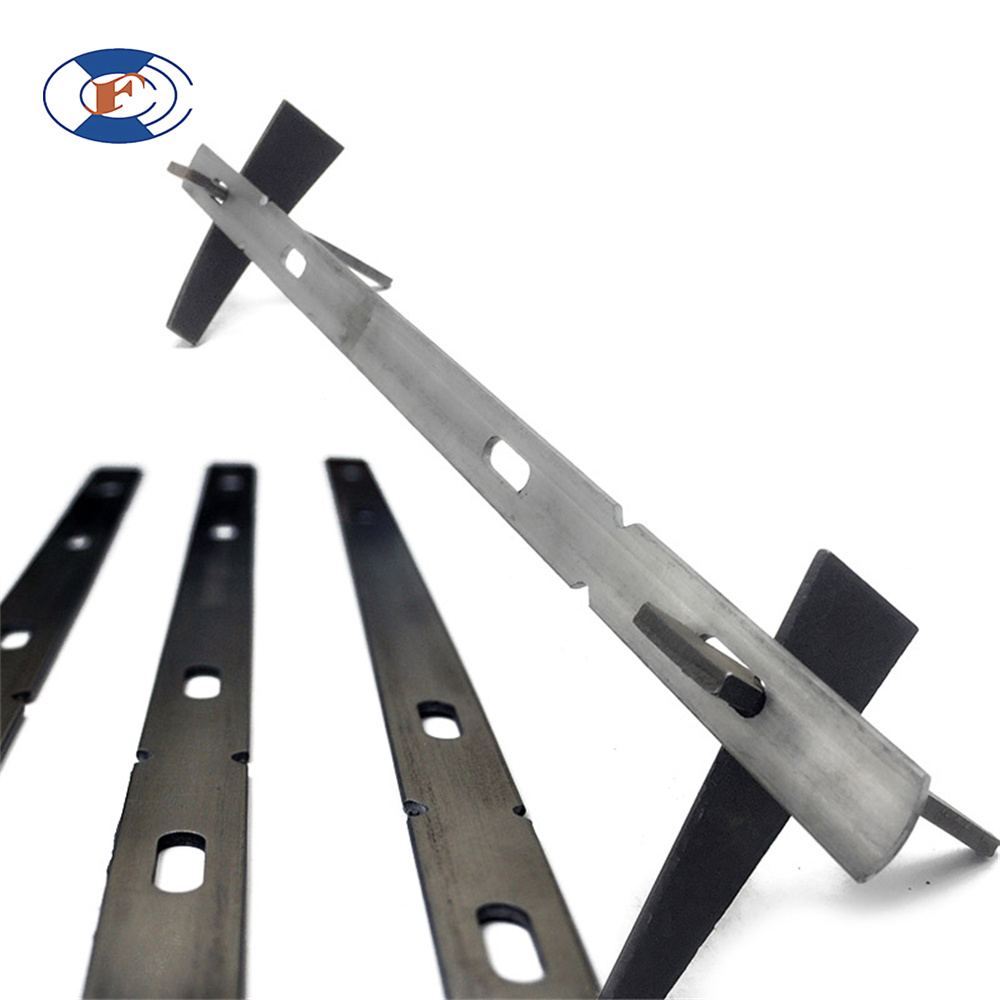

At its core, a Snap Tie is a mechanical fastener used in concrete formwork. Concrete formwork, also known as shuttering or molds, is the temporary structure used to hold and shape fresh concrete until it sets and gains enough strength to support its weight.

Snap Ties serve as the backbone of this formwork, holding it securely in place during the pouring and curing process.

Concrete Snap Tie with Washer: Adding Stability and Reusability

The Concrete Snap Tie with Washer is a popular choice in the construction industry due to its reliability and reusability. Here’s how it works:

Installation: A Snap Tie consists of a threaded rod and a washer. During formwork assembly, the rod is inserted through the formwork, and the washer is placed on the exposed end of the rod inside the form.

Tightening: As the concrete is poured into the formwork, the Snap Tie is tightened from the exterior, securing the form panels together. This provides stability and prevents the form from bulging or shifting due to the pressure of the concrete.

Removal: Once the concrete has cured, the Snap Tie can be easily removed from the outside of the form. The washer remains embedded in the concrete, leaving behind a smooth finish.

The key advantage of the Concrete Snap Tie with Washer is its reusability. After removal, it can be cleaned and used again in future projects, making it a cost-effective choice for construction professionals.

Concrete Snap Ties with Plastic Cone: Enhancing Efficiency

Concrete Snap Ties with Plastic Cone offer added efficiency and convenience in formwork assembly:

Installation: Similar to the Snap Tie with Washer, a threaded rod is inserted through the formwork. However, in this case, a plastic cone is placed on the exposed end of the rod inside the form.

Tightening: As the concrete is poured, the Snap Tie is tightened from the outside, securing the form panels. The plastic cone serves as a spacer, ensuring that the tie remains in the desired position within the concrete.

Stripping: After the concrete cures, the Snap Tie can be removed from the outside. The plastic cone remains in the concrete and can be snapped off at the designated break point, leaving a neat finish.

Concrete Snap Ties with Plastic Cone streamline the formwork process by eliminating the need for additional washers and providing a clean break point for efficient stripping.

What is snap tie wedge and jahn a bracket

Next we will introduce the accessories used in combination with snpa tie.

Understanding the Jahn Bracket: Your Formwork Ally

When it comes to securing and aligning formwork, the Jahn Bracket is your trusted ally. This versatile component is engineered to:

Enhance Stability: The Jahn Bracket reinforces the stability of your formwork, ensuring that it remains in the desired position during the pouring of concrete. This stability is essential for maintaining the integrity and precision of your concrete structures.

Support Heavy Loads: Whether you’re working on a residential project or a large-scale construction endeavor, the Jahn Bracket can handle the load. Its robust design is capable of supporting the weight of concrete forms, offering you peace of mind and reliability.

Streamline Alignment: Achieving precise alignment of form panels is crucial for achieving impeccable concrete finishes. The Jahn Bracket simplifies this task, helping you align form panels accurately and efficiently.

Snap Tie Wedge: Precision and Ease

The Snap Tie Wedge is an indispensable companion to your snap tie applications. Here’s how it can benefit your construction projects:

Effortless Tightening: The Snap Tie Wedge simplifies the process of tightening snap ties. Its ergonomic design allows for easy insertion and tightening, saving you valuable time and effort on the job site.

Consistent Pressure: Achieving consistent pressure during the concrete pouring process is crucial for avoiding issues like formwork blowouts. The Snap Tie Wedge ensures that pressure is evenly distributed, reducing the risk of such complications.

Clean and Efficient Removal: Once the concrete has cured, the removal of snap ties becomes a breeze with the Snap Tie Wedge. It facilitates clean and efficient stripping, leaving you with a smooth concrete surface.

The Perfect Pairing for Your Snap Tie Applications

When combined with snap ties, the Jahn Bracket and Snap Tie Wedge create a winning team that enhances the precision and efficiency of your formwork. These components are designed to work seamlessly with snap ties, making them the perfect additions to your construction toolkit.

If you want to know more about concrete wall tie, you can read this article: What Is a Wall Tie

In Conclusion: Choosing the Right Snap Tie for Your Project

Snap Ties are indispensable components of concrete formwork, ensuring stability and facilitating the construction process. Whether you opt for the durability and reusability of Concrete Snap Ties with Washer or the efficiency of Concrete Snap Ties with Plastic Cone, selecting the right type depends on your project’s specific requirements.

At Qingdao H&F, we offer a comprehensive range of concrete forming accessories, including Snap Ties, to meet your construction needs. Our 20 years of industry experience, commitment to quality, and support for customization ensure that you have access to top-notch products tailored to your unique projects.

Explore our offerings and discover the perfect Snap Tie solution for your next construction venture.Send us an inquiry to get a free quote.

FAQS about Snap Tie

Why choose Concrete Snap Ties with Washer for construction projects?

Uncover the benefits of opting for Concrete Snap Ties with Washer, including increased reliability, reusability, and a smooth finish after concrete curing.

Can Concrete Snap Ties with Plastic Cone enhance formwork efficiency?

Explore how the innovative design of Concrete Snap Ties with Plastic Cone adds efficiency and convenience to the formwork assembly process, eliminating the need for additional components.

What role do Snap Tie Wedges play in the concrete construction process?

Learn about the indispensable role of Snap Tie Wedges in simplifying the tightening and removal of snap ties, saving valuable time and effort on construction sites.

How does the Jahn Bracket contribute to formwork stability and alignment?

Dive into the versatility of the Jahn Bracket, understanding how it reinforces formwork stability, supports heavy loads, and streamlines the alignment of form panels.

Why is achieving consistent pressure crucial in the concrete pouring process?

Gain insights into the significance of consistent pressure during concrete pouring and how the Snap Tie Wedge ensures even distribution, minimizing the risk of formwork complications.

What makes the combination of Snap Ties, Jahn Brackets, and Snap Tie Wedges a winning team?

Discover the synergies between Snap Ties, Jahn Brackets, and Snap Tie Wedges, creating a powerhouse that enhances precision and efficiency in concrete formwork.

How does the reusability of Concrete Snap Ties with Washer benefit construction professionals?

Explore the cost-effective advantages of choosing Concrete Snap Ties with Washer, which can be easily cleaned and reused for future construction projects.

In what ways do Concrete Snap Ties with Plastic Cone streamline the formwork process?

Understand how the inclusion of Plastic Cones in Concrete Snap Ties simplifies formwork assembly, eliminating the need for additional washers and providing a clean break point for efficient stripping.

What types of construction projects can benefit from the Qingdao H&F Snap Tie system?

Learn about the diverse applications of the Qingdao H&F Snap Tie system and how it caters to the unique requirements of various construction ventures.