A wall tie is a construction component used to connect and secure two parallel walls together in a building or structure. It helps provide stability, structural integrity, and resistance against forces such as wind, seismic activity, or lateral pressure.

There are several types of wall ties available, including:

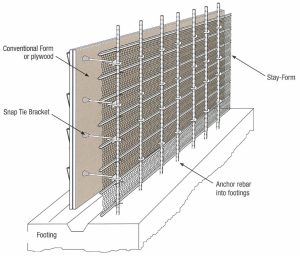

Snap Tie: A snap tie is a type of wall tie that consists of two parts – a metal rod or flat strap and a separate “snap” or wedge-shaped connector. The tie is inserted through the formwork (typically during concrete pouring) and tightened using the snap, which holds the formwork in place until the concrete sets.Snap tie needs to be used in conjunction with plastic cone.

Full Tie: A full tie is a wall tie that extends through the entire width of the wall. It is embedded into both sides of the wall, providing a strong connection and stability.It needs to be used in combination with wedge pin and straight &curved wedge.

Nominal Tie: A nominal tie is a shorter wall tie that is embedded into one side of the wall, typically the outer layer of masonry or concrete. It provides some connection strength but not as robust as a full tie.It needs to be used in combination with head pin and straight &curved wedge.

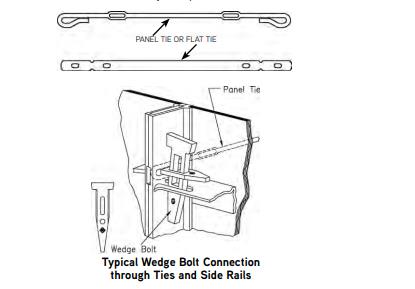

X Flat Tie: An X flat tie is a type of wall tie that is shaped like the letter “X.” It is embedded into the formwork or wall, creating an interlocking connection between the two walls and enhancing their stability.It needs to be used in combination with wedge bolt and straight &curved wedge.

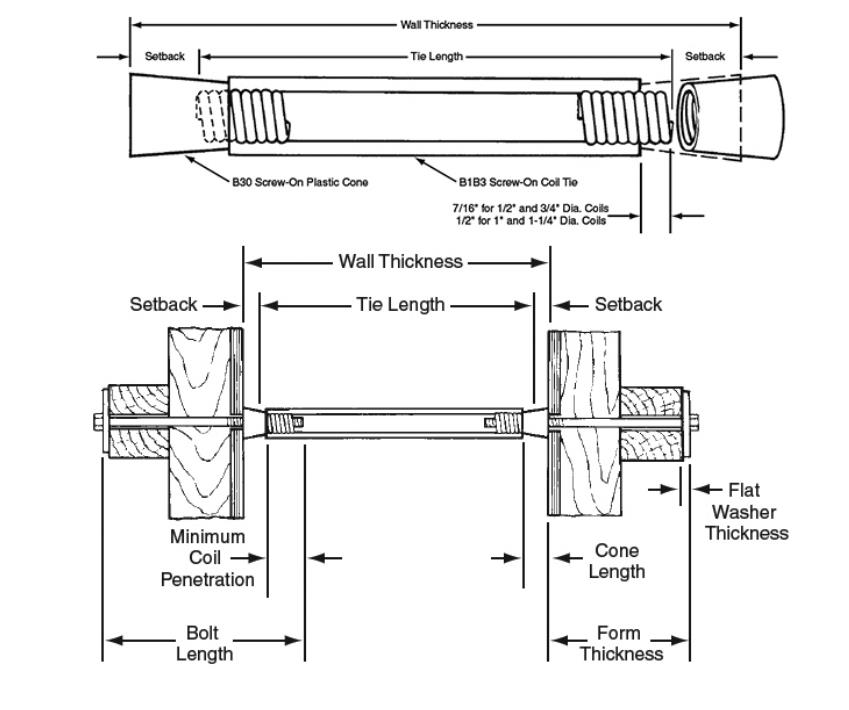

Coil Tie: A coil tie, as mentioned before, is a threaded rod with coil-like loops on each end. It is used to connect and secure parallel walls together, typically by embedding the loops into the mortar joints of the masonry walls.

Read on and you’ll learn in detail what they are used for!

How are They Installed?

Snap Tie Installation:

Prepare the formwork: Set up the formwork panels in the desired position for the wall. Ensure they are properly aligned and secured.

Insert the snap ties: Place the snap ties through the formwork, evenly spacing them along the wall. The snap ties should be inserted through the holes or slots in the formwork panels.

Tighten the snap ties: Attach the wedge-shaped snap or connector to the end of each tie and tighten it securely. This will hold the formwork in place until the concrete sets.

Repeat the process: Continue inserting and tightening snap ties along the entire length of the formwork, ensuring they are properly aligned and secured.

Full Tie Installation:

Prepare the wall: Build the parallel walls, ensuring they are plumb and aligned.

Position the full ties: Place the full ties at the desired spacing between the walls, typically extending through the entire width of the walls.

Secure the ties: Attach appropriate fasteners or clips to each end of the full tie, ensuring they are securely connected to both walls.

Repeat the process: Install additional full ties at regular intervals along the height and length of the walls to provide adequate support and stability.

Nominal Tie Installation:

Prepare the wall: Construct the walls, ensuring they are properly aligned and positioned.

Position the nominal ties: Place the nominal ties at the desired spacing along the outer layer of the wall, typically extending partially into the inner layer.

Embed the ties: Insert the nominal ties into the mortar joints of the outer layer of the wall, ensuring they are embedded securely.

Repeat the process: Install additional nominal ties as per the required spacing and design considerations.

X Flat Tie Installation:

Prepare the formwork or wall: Set up the formwork panels or construct the walls, ensuring proper alignment.

Position the X flat ties: Place the X flat ties diagonally across the formwork or wall, forming an X pattern.

Secure the ties: Attach appropriate fasteners or clips to each end of the X flat tie, ensuring they are securely connected to the formwork or wall.

Repeat the process: Install additional X flat ties at regular intervals, creating a strong interlocking connection.

Coil Tie Installation:

Prepare the wall: Construct the parallel walls, ensuring they are properly aligned and positioned.

Position the coil ties: Place the coil ties at the desired spacing along the walls, ensuring they are evenly distributed.

Embed the ties: Insert the coil tie loops into the mortar joints of each wall, ensuring they are embedded securely.

Repeat the process: Install additional coil ties as per the required spacing and design considerations.

How Do Wall Ties Work?

Snap Tie:

Working Principle: Once the snap tie is in place, a wedge or snap is attached to the exposed end of the tie and tightened. This compresses the formwork panels together, holding them in position until the concrete sets. The snap tie provides lateral stability and ensures the formwork maintains its desired shape during concrete pouring and

curing.

Full Tie:

Working Principle: Full ties work by providing a continuous and strong connection between the walls. They resist forces such as wind or soil pressure that act on the walls, preventing them from separating or leaning. Full ties distribute loads and stresses evenly across the walls, improving their overall stability.

Nominal Tie:

Working Principle: The nominal tie provides a partial connection between the two walls. While not as robust as a full tie, it helps resist some lateral forces and contributes to the overall stability of the structure.

X Flat Tie:

Working Principle: X flat ties work by interlocking with adjacent ties, reinforcing the formwork. They provide lateral stability to the formwork during concrete pouring and curing, preventing it from shifting or deforming under the pressure of the concrete.

Coil Tie:

Working Principle: The coil tie connects the walls by creating a mechanical bond within the mortar. It enhances the structural stability of the walls, preventing them from separating or leaning. Coil ties distribute forces between the walls, improving their overall resistance to external pressures.

Each type of wall tie is designed to provide connections and stability between parallel walls, ensuring their structural integrity. The installation process may vary slightly depending on the specific tie, but the underlying principle remains consistent—creating a secure and robust linkage between the walls to withstand forces and maintain structural stability.

Wall Tie Selection

Snap Tie:

Suitable for: Snap ties are commonly used in concrete formwork systems where quick installation and removal of the formwork are required.

Benefits: Snap ties are easy to install, and their wedge-based system allows for rapid assembly and disassembly of formwork.

Considerations: Snap ties are typically used for temporary applications and may not provide the same long-term stability as other types of ties.

Full Tie:

Suitable for: Full ties are suitable for parallel masonry or concrete walls that require a strong and continuous connection.

Benefits: Full ties provide a robust and secure connection between walls, ensuring structural stability and load-bearing capacity.

Considerations: Full ties require careful installation and may require drilling or embedding into the walls. They are typically more permanent and may be more difficult to remove.

Nominal Tie:

Suitable for: Nominal ties are often used in situations where a partial connection between the walls is sufficient or when full ties are not feasible.

Benefits: Nominal ties offer some degree of lateral stability and connection while being simpler to install than full ties.

Considerations: Nominal ties may not provide the same level of strength and stability as full ties. They are generally used in applications where reduced loads or movement is expected.

X Flat Tie:

Suitable for: X flat ties are commonly used in formwork systems, particularly when creating walls with interlocking features or angular shapes.

Benefits: X flat ties provide diagonal reinforcement, offering additional stability to the formwork and resisting lateral pressure during concrete pouring.

Considerations: X flat ties require careful positioning and alignment during installation. They may be more suitable for specific formwork designs and applications.

Coil Tie:

Suitable for: Coil ties are often used in masonry construction where parallel walls need to be connected and reinforced.

Benefits: Coil ties provide a mechanical bond between the walls, enhancing their stability and preventing separation.

Considerations: Coil ties require embedding into the mortar joints of the walls during construction. The spacing and depth of the ties should be determined based on engineering requirements and local building regulations.

Conclusion about Wall Tie

Snap tie: Quick and easy installation for forming concrete walls.

Full tie: Provides maximum strength and stability for heavy-duty structures.

Nominal tie: Offers a balance between strength and cost-effectiveness for mid-sized projects.

Coil tie: Specifically designed for curved or irregularly shaped structures.

X flat tie: Unique design allows for use in narrow spaces, accommodating tight formwork arrangements.

FAQ about Wall Tie

What is the main advantage of using snap ties over other tying systems

Answer: Snap ties offer quick and easy installation, saving time on construction sites.

Are full ties suitable for all types of construction projects?

Answer: Full ties are ideal for heavy-duty structures that require maximum strength and stability.

Can nominal ties provide adequate support for large-scale projects?

Answer: While nominal ties are versatile, they are best suited for mid-sized projects that require a balance between strength and cost-effectiveness.

What makes coil ties different from other tying systems?

Answer: Coil ties are specifically designed for curved or irregularly shaped structures, providing flexibility to adapt to the formwork’s contours.

Can x flat ties be used in tight spaces?

Answer: Yes, x flat ties have a unique design that allows them to be used in narrow spaces, making them suitable for tight formwork arrangements.

Are snap ties reusable, or are they single-use only?

Answer: Snap ties are typically reusable, making them a cost-effective option for multiple construction projects.

Are full ties compatible with various formwork materials?

Answer: Yes, full ties are compatible with different formwork materials, such as wood, metal, or plastic.

Do nominal ties require additional reinforcement for high-stress areas?

Answer: In areas with higher stress, it is recommended to use additional nominal ties or consider upgrading to full ties for added strength.

Can coil ties be adjusted to fit different curve sizes?

Answer: Yes, coil ties can be easily adjusted to accommodate various curve sizes, making them versatile for curved formwork designs.

Are x flat ties suitable for vertical or horizontal formwork?

Answer: X flat ties can be used for both vertical and horizontal formwork, providing secure connections in either orientation.